Silicon nano cone array coated with gold film as well as preparation method and application thereof

A silicon nanometer and cone array technology is applied in the fields of nanocone arrays and preparation, and can solve the problems that the product cannot be used for the detection of clenbuterol hydrochloride, the product cannot be obtained, the preparation method is complicated, and the production method is simple and convenient, and the preparation method is simple. , consistent and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The concrete steps of preparation are:

[0038] Step 1, first synthesize a single-layer colloidal crystal template with polystyrene colloidal spheres with a diameter of 250 nm on a silicon substrate through the gas-liquid interface self-assembly technology; Crystal silicon wafer. Then put the silicon substrate synthesized with a single-layer colloidal crystal template on it at a flow rate of 30 cm 3 / min and a pressure of 3.4Pa in a sulfur hexafluoride atmosphere for 3 minutes to obtain a silicon substrate with an ordered array of silicon nanocones placed thereon; wherein, the power of the plasma etching is 220W.

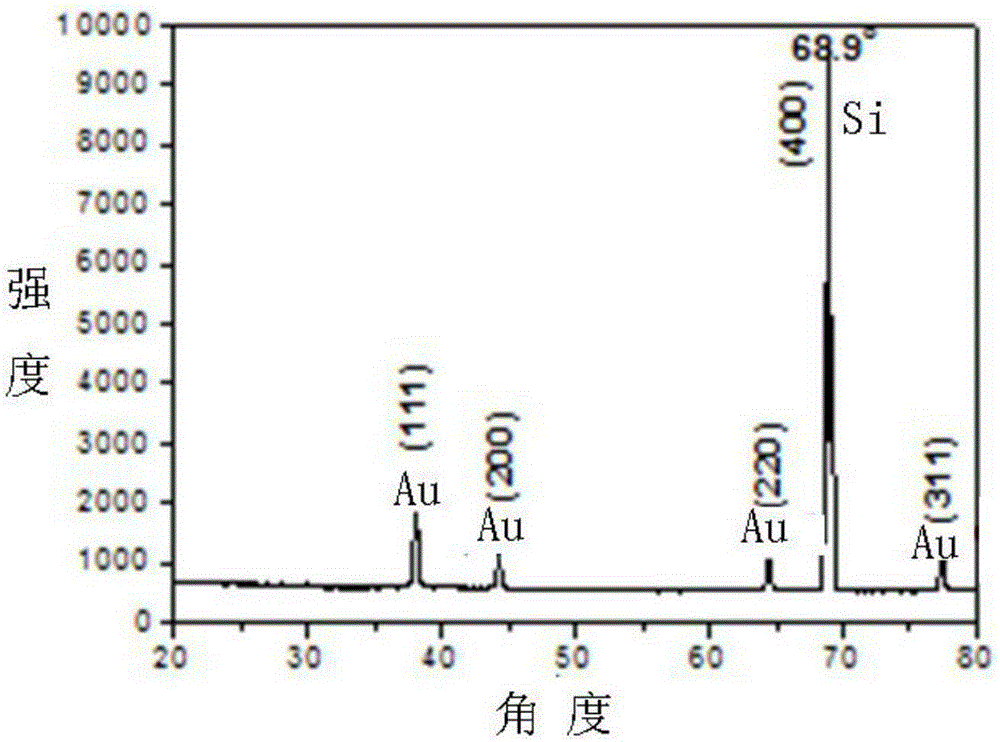

[0039] Step 2, using ion beam sputtering deposition (or thermal evaporation deposition) technology, depositing a gold film with a thickness of 15nm on a silicon substrate with an ordered array of silicon nanocones placed thereon; wherein, ion beam sputtering deposits a gold film When the deposition current is 18mA and the time is 5min, the obtained figure ...

Embodiment 2

[0041] The concrete steps of preparation are:

[0042] Step 1, first synthesize a single-layer colloidal crystal template with polystyrene colloidal spheres with a diameter of 280 nm on a silicon substrate through the gas-liquid interface self-assembly technology; Crystal silicon wafer. Then the silicon substrate synthesized with a single-layer colloidal crystal template is placed in a flow rate of 33 cm 3 / min and a pressure of 3.3Pa in a sulfur hexafluoride atmosphere for 3.3 minutes to obtain a silicon substrate with an ordered array of silicon nanocones; wherein, the power of the plasma etching is 210W.

[0043] Step 2, using ion beam sputtering deposition (or thermal evaporation deposition) technology, depositing a gold film with a thickness of 18nm on a silicon substrate with an ordered array of silicon nanocones placed thereon; wherein, the gold film is deposited by ion beam sputtering When the deposition current is 19mA and the time is 4.5min, the obtained figure 1 ...

Embodiment 3

[0045] The concrete steps of preparation are:

[0046] Step 1, first synthesize a single-layer colloidal crystal template with polystyrene colloidal spheres with a diameter of 300 nm on a silicon substrate through the gas-liquid interface self-assembly technology; Crystal silicon wafer. Place the silicon substrate on which the monolayer colloidal crystal template is synthesized at a flow rate of 35 cm 3 / min and a pressure of 3.2Pa in a sulfur hexafluoride atmosphere for 3.5 minutes to obtain a silicon substrate with an ordered array of silicon nanocones placed thereon; wherein, the power of the plasma etching is 200W.

[0047] Step 2, using ion beam sputtering deposition (or thermal evaporation deposition) technology, depositing a gold film with a thickness of 20nm on a silicon substrate with an ordered array of silicon nanocones placed thereon; wherein, ion beam sputtering deposits a gold film When the deposition current is 20mA and the time is 4min, the obtained figure 1 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com