Thruster layout method for truss type GEO (geostationary orbit) satellite adopting subdivision optimization design

A technology of subdivision optimization design and thruster layout, which is applied in the direction of aerospace vehicle propulsion system devices, etc., can solve the problems of installation, failure, and inability of thrusters to be installed on the opposite floor and the back floor, etc., to overcome interference torque, high satellite The effect of track change efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The propellant storage tanks of the truss-type GEO satellites are usually in the propulsion service module, and it is possible to carry out a modular design of compartments, but the center of mass of the truss-type GEO satellite is obviously higher than the Z-axis coordinates of the upper end of the propulsion service module, making the subdivision module It is very difficult to optimize the optimized thruster layout.

[0024] The present invention proposes a truss-type GEO satellite thruster layout method with subdivision optimization design, which not only needs to meet the basic requirements of subdivision modular design in which the truss-type GEO satellite thrusters are all in the propulsion service cabin layout, but also optimizes the thruster layout.

[0025] like figure 1 Shown is the flowchart of the method of the present invention. It is characterized in that the steps are as follows:

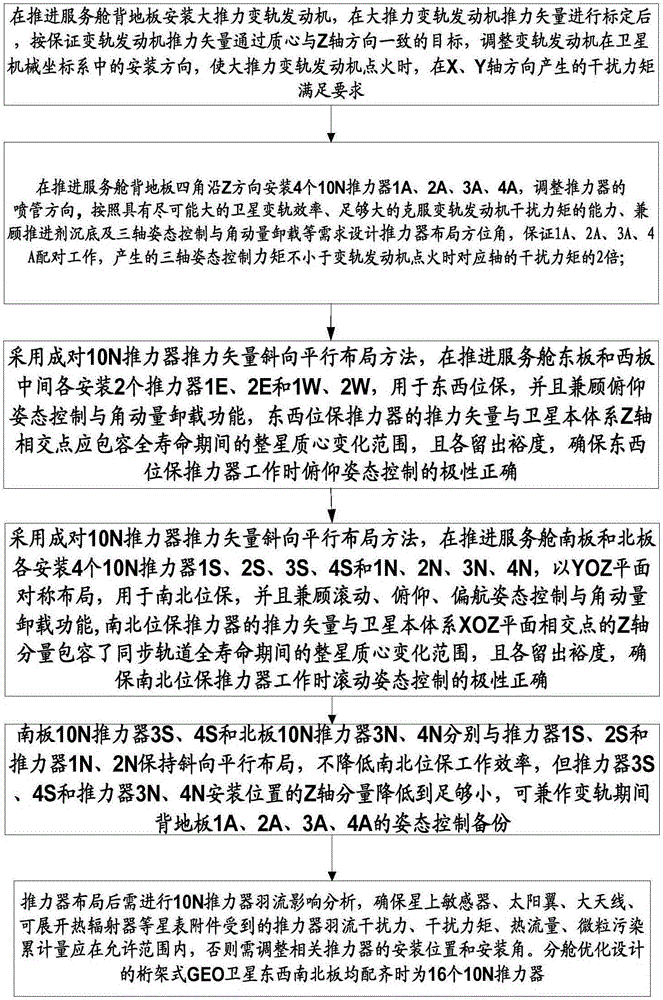

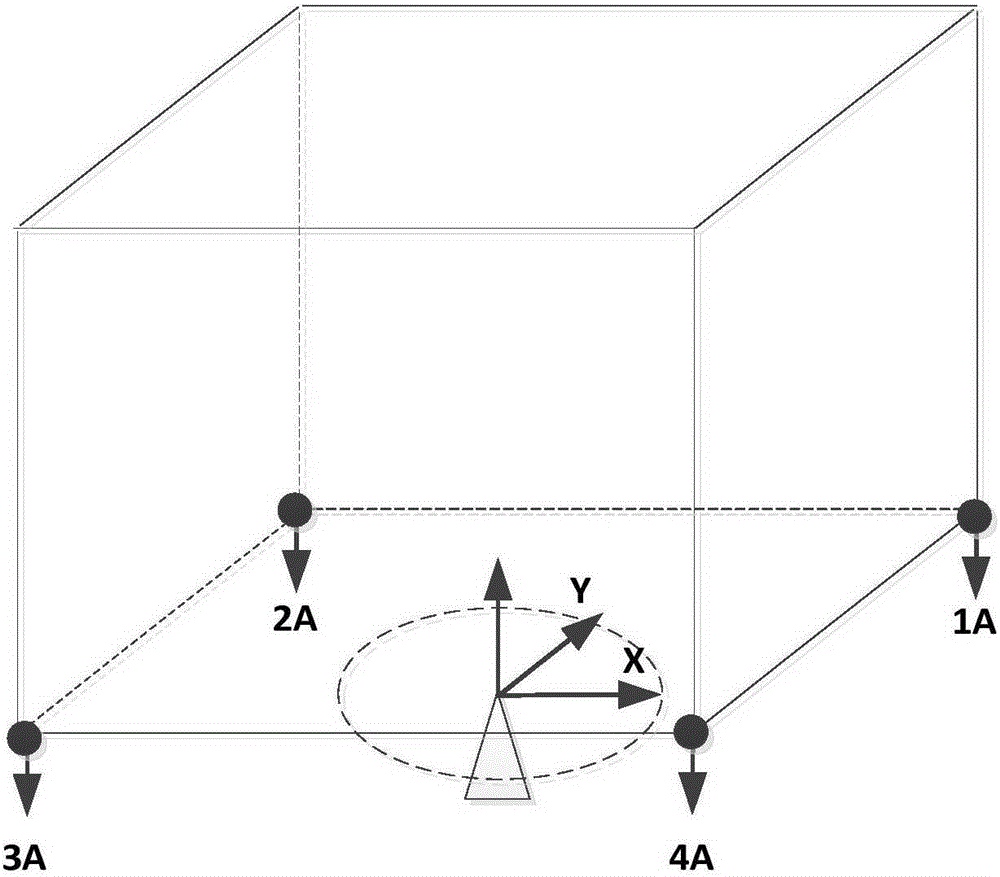

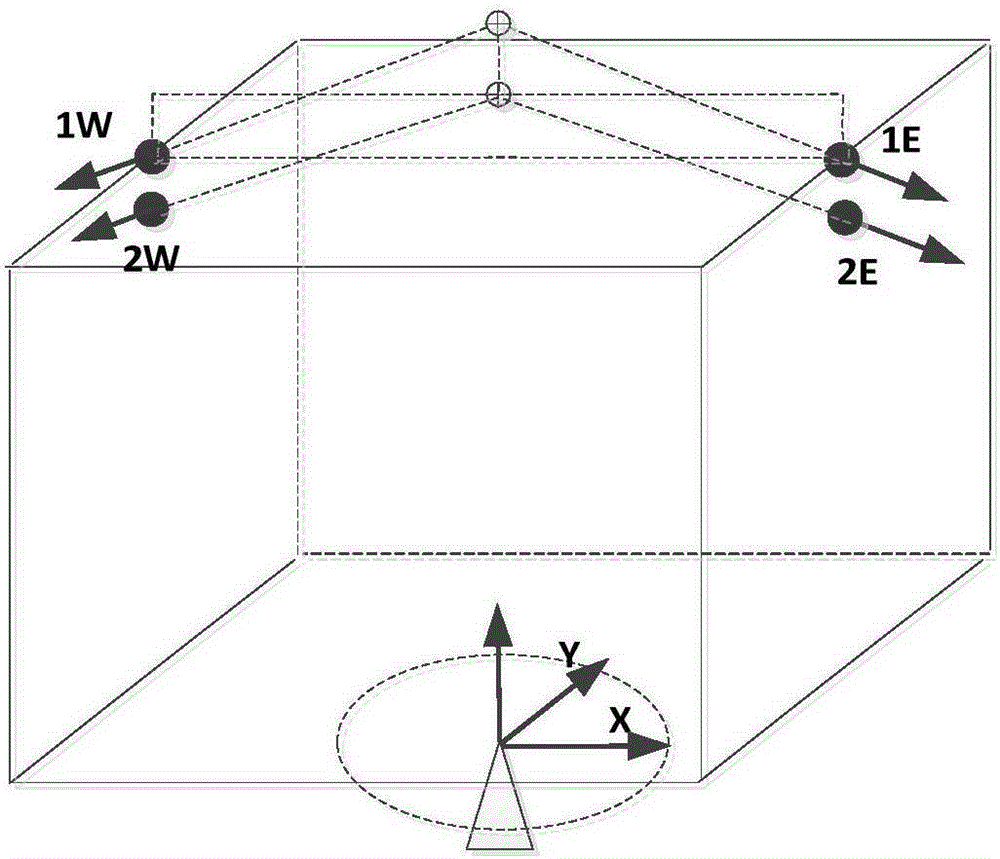

[0026] (1) Install the high-thrust orbit-changing engine on the back flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com