Method and device for online cleaning and detection of first lens of fusion device

A beam conversion and beam technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to transmit optical signals, inability to replace optical components, and decreased reflectivity of optical components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

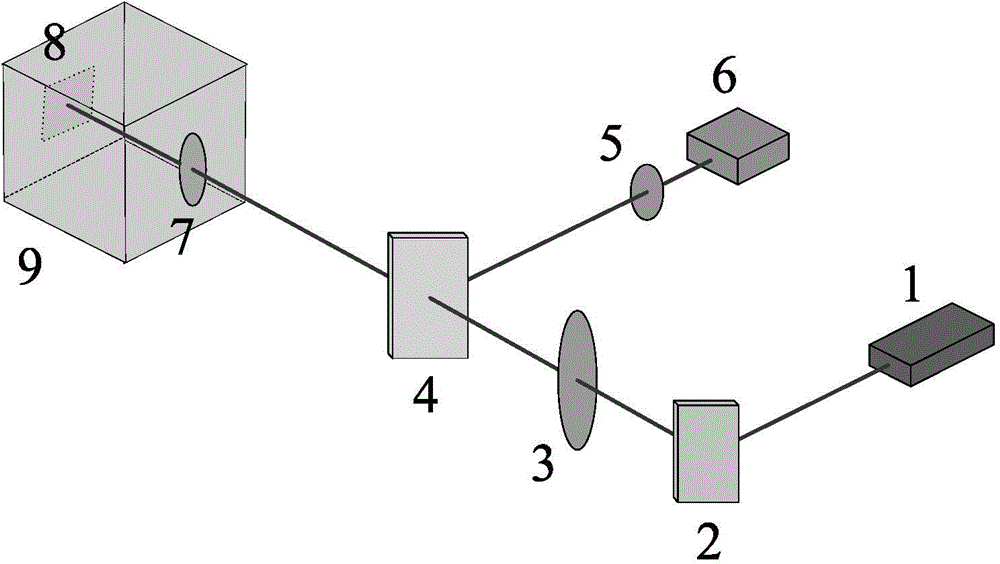

[0020] Such as figure 1 As shown, a device for online cleaning and detection of the first mirror of a fusion device includes a pulsed laser, a two-dimensional moving galvanometer, a CCD camera, an auxiliary light source, and an optical transmission system. Among them, the two-dimensional galvanometer system 2, the beam conversion system 3, the two-color beam splitter 4, the fusion device diagnostic window 7, the first mirror 8, and the fusion device vacuum chamber 9 are arranged along a straight line, and the fusion device vacuum chamber 9 is provided with The diagnostic window 7 of the fusion device, the pulse laser 1 is arranged on one side of the two-dimensional vibrating mirror system 2 , the auxiliary light source 5 is arranged on one side of the two-color beam splitter 4 , and the CCD camera 6 is arranged on the outside of the auxiliary light source 5 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com