Honeycombed catalyst for low-temperature denitration and preparation method

A honeycomb catalyst and low-temperature denitrification technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of inability to meet the technical requirements of low-temperature denitrification and the decline in catalytic efficiency, and achieve good acid resistance. Sulfur corrosion performance, increased load capacity and adhesion, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Carrier activation:

[0021] Weigh 1000g of zeolite powder and dissolve it in a nitric acid solution with a mass fraction of 20%. Dissolve it completely. Use a constant temperature water bath at 80°C to continuously heat and oscillate for 5 hours, then filter out the zeolite powder and wash the zeolite powder with deionized water until The pH value of the washing waste liquid is between 7 and 7.5, and then the zeolite powder is dried by controlling the temperature in an oven at 110°C to obtain activated zeolite powder for use;

[0022] (2) Loading of active ingredients:

[0023] Weigh titanium dioxide, ferric nitrate, and manganese nitrate to be 1250g, 625g, and 250g respectively, add a mixed solution formed by deionized water and 25% ammonia water according to the volume ratio of 1:1, and the usage amount of the mixed solution makes the active components completely Just dissolve; add 250g of the activated zeolite powder prepared in (1) after stirring continuously ...

Embodiment 2

[0027] (1) Carrier activation: the same as in Example 1.

[0028] (2) Active ingredient load: same as Example 1.

[0029] (3) Catalyst molding:

[0030] Weigh the catalyst initial material prepared in (2) 830g, Get stearic acid, methacrylic acid-2-carboxyethyl ester, glass fiber again 51g, 41g, 62g , Mix well to form a mixture, then add deionized water, the amount of deionized water used is to make the above mixture just become muddy. Afterwards, the muddy mixture is subjected to vacuum mud refining, aged under constant temperature and humidity conditions, shaped, dried, and calcined in a tunnel kiln until fully dried to make a honeycomb-shaped new low-temperature denitrification catalyst.

Embodiment 3

[0032] (1) Carrier activation: the same as in Example 1.

[0033] (2) Active ingredient load: same as Example 1.

[0034] (3) Catalyst molding:

[0035] Weigh 830g of the initial catalyst material prepared in (2), and then take stearic acid, 2-carboxyethyl methacrylate, and glass fiber as 60g, 49g, and 65g respectively, and fully mix to form a mixture, and then add deionized water , the amount of deionized water used is to make the above mixture just become muddy. Afterwards, the muddy mixture is subjected to vacuum mud refining, aged under constant temperature and humidity conditions, shaped, dried, and calcined in a tunnel kiln until fully dried to make a honeycomb-shaped new low-temperature denitrification catalyst.

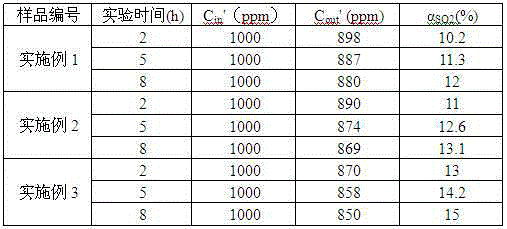

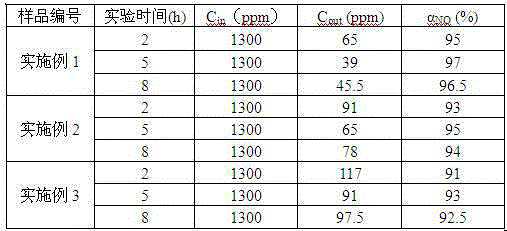

[0036] , sample catalyst experiment and test result calculation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com