Preparation method of Ni-loaded honeycomb ceramic catalyst suitable for VPCE

A honeycomb ceramic and catalyst technology, which is applied in the field of preparation of Ni-supported honeycomb ceramic catalyst, can solve the problems of poor active metal binding force, high catalyst cost, small specific surface area, etc. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

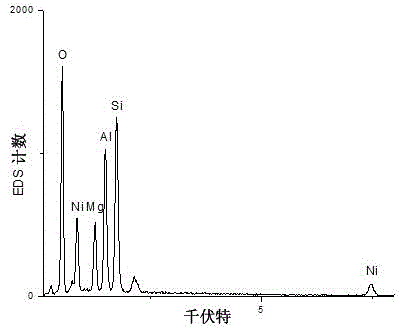

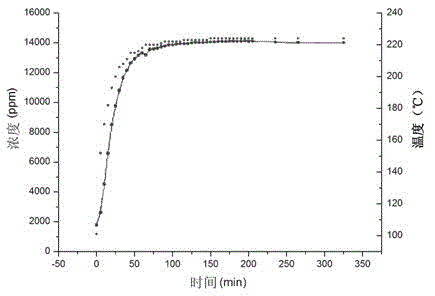

[0034] Such as figure 1 As shown, the present invention provides a Ni-loaded honeycomb ceramic catalyst, which is applicable to hydrogen-water vapor phase catalytic exchange (VPCE). The invention uses honeycomb ceramics as a carrier, elemental nickel (Ni) as a catalytic active component, and processes the honeycomb ceramics by drying, equal volume-liquid phase impregnation, roasting and hydrogen reduction to obtain a catalyst. The process includes the following:

[0035] (1) Dry the honeycomb ceramics at 150°C and use it as a carrier;

[0036] (2) Measure the saturated Ni(NO 3 ) 2 aqueous solution, and then put the carrier into the aqueous solution and soak for more than 12 hours until the carrier will be saturated with Ni(NO 3 ) 2 The aqueous solution is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com