High-content glucosamine sulfate tablet and preparation method

A technology of glucosamine sulfate and glucosamine sulfate potassium salt, applied to medical preparations containing active ingredients, sugar-coated pills, pharmaceutical formulas, etc., which can solve the problems of low content of effective drugs, low bioavailability, and low content of glucosamine , to achieve the effect of round and smooth appearance, lower production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

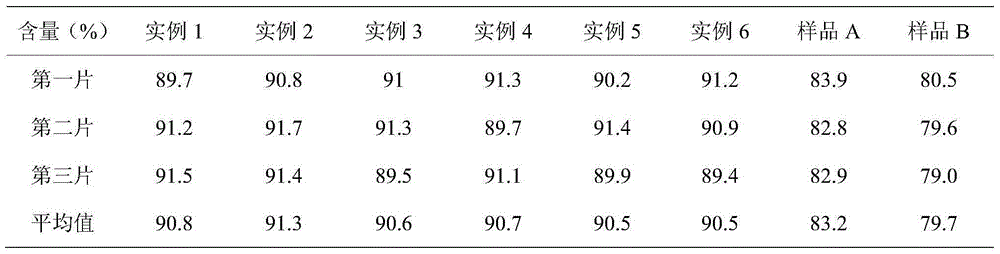

Examples

Embodiment 1

[0026] Preparation prescription: 87 parts of D-glucosamine sulfate potassium salt, 2.5 parts of povidone K30, 2.2 parts of microcrystalline cellulose, 1.5 parts of sodium carboxymethyl starch, 0.8 parts of magnesium stearate, 0.5 parts of silicon dioxide, film pack 1.3 parts of clothing powder, 4 parts of ultrapure water.

[0027] Preparation process: filter D-glucosamine sulfate potassium salt, microcrystalline cellulose, povidone K30 and carboxymethyl starch sodium through a 80-mesh sieve. Accurately weigh the above raw materials according to the formula, add them to the mixing granulator for crushing and stirring. Add an appropriate amount of ultrapure water, pass through a 20-mesh sieve and granulate. Put the granules into the dryer to remove moisture, set the fan frequency to 25Hz, the inlet air temperature to 65°C, and the temperature of the material to be about 45°C. After drying, the moisture content of the granules decreases. Add lubricant magnesium stearate and gl...

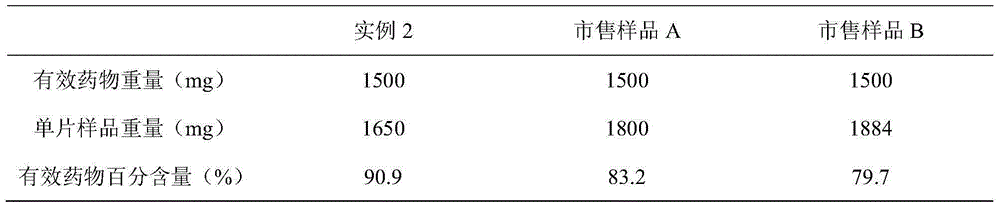

Embodiment 2

[0029] Preparation prescription: 91 parts of D-glucosamine sulfate potassium salt, 2.7 parts of povidone K30, 2.1 parts of microcrystalline cellulose, 2.2 parts of sodium carboxymethyl starch, 0.4 parts of magnesium stearate, 0.4 parts of silicon dioxide, film pack 0.8 parts of clothing powder, 5 parts of ultrapure water.

[0030] Preparation process: filter D-glucosamine sulfate potassium salt, microcrystalline cellulose, povidone K30 and carboxymethyl starch sodium through a 80-mesh sieve. Accurately weigh the above raw materials according to the formula, add them to the mixing granulator for crushing and stirring. Add an appropriate amount of ultrapure water, pass through a 20-mesh sieve and granulate. Put the granules into the dryer to remove moisture, set the fan frequency to 35Hz, the inlet air temperature to 75°C, and the temperature of the material to be about 50°C. After drying, the moisture content of the granules decreases. Add lubricant magnesium stearate and gl...

Embodiment 3

[0032] Preparation prescription: 90 parts of D-glucosamine sulfate potassium salt, 2.9 parts of povidone K30, 2.4 parts of microcrystalline cellulose, 1.7 parts of carboxymethyl starch sodium, 0.5 parts of magnesium stearate, 0.6 parts of silicon dioxide, film pack 1.2 parts of clothing powder, 6 parts of ultrapure water.

[0033] Preparation process: filter D-glucosamine sulfate potassium salt, microcrystalline cellulose, povidone K30 and carboxymethyl starch sodium through a 80-mesh sieve. Accurately weigh the above raw materials according to the formula, add them to the mixing granulator for crushing and stirring. Add an appropriate amount of ultrapure water, pass through a 20-mesh sieve and granulate. Put the granules into the dryer to remove moisture, set the fan frequency to 45Hz, the inlet air temperature to 85°C, and the temperature of the material to be about 55°C. After drying, the moisture content of the granules is reduced. Add lubricant magnesium stearate and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com