Production of aluminium-scandium alloys

一种合金、合金化元素的技术,应用在生产铝-钪系合金领域,能够解决缓慢、追加高纯Sc金属成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

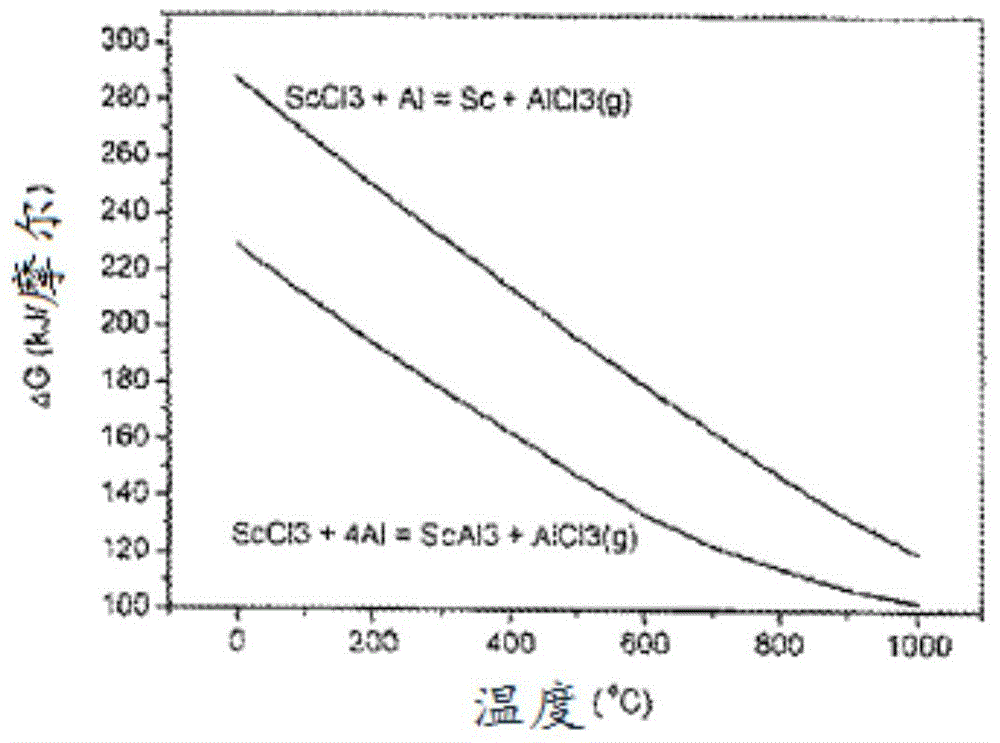

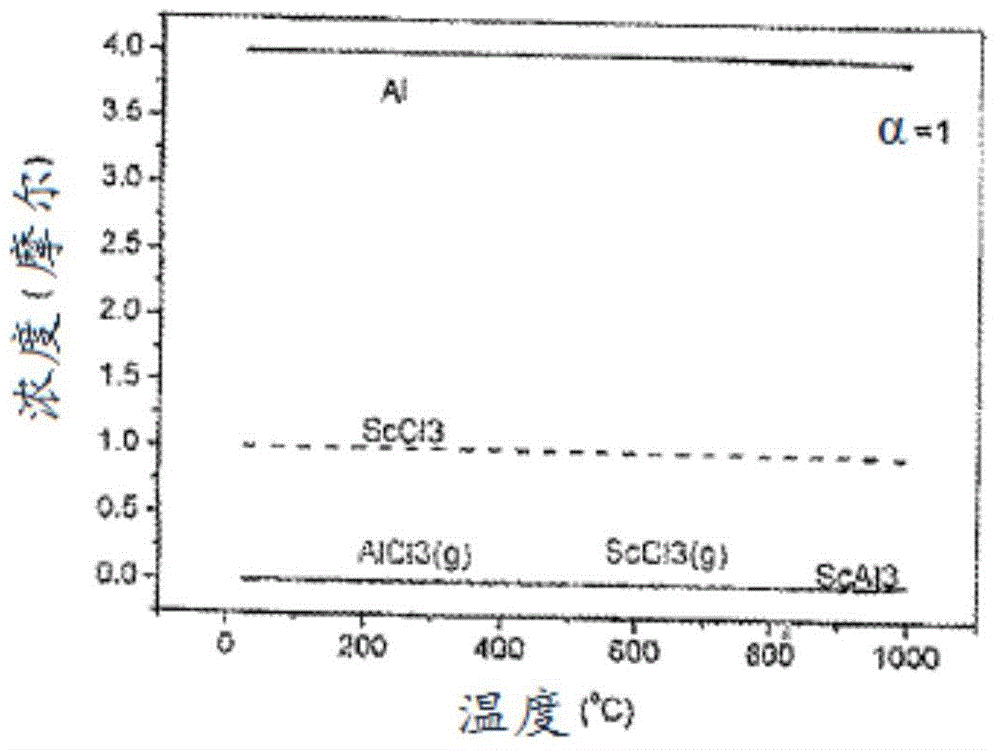

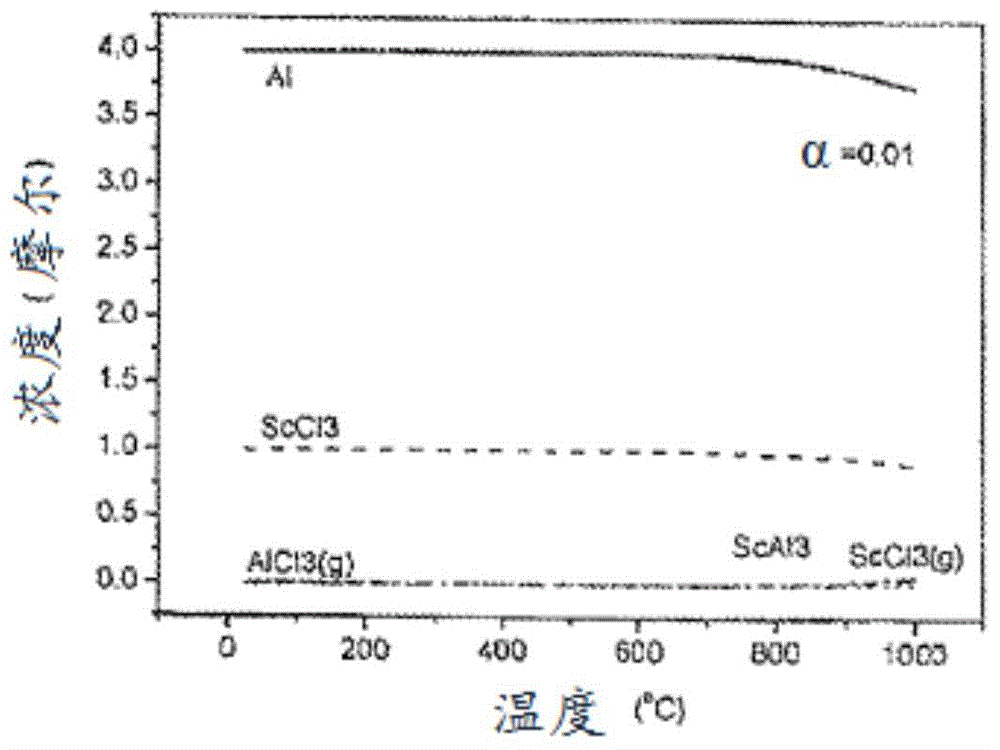

Method used

Image

Examples

Embodiment 1

[0136] Embodiment 1: produce Al 3 Sc powder

[0137] 4Al to 1ScCl 3 The molar ratio of 5g of Al powder with an average particle size of less than 15 microns to ScCl 3 Powder mix. The material is then placed in a quartz tube and heated at a temperature between 600°C and 900°C and a pressure below 100 mbar. The temperature was first held at 600°C for 10 minutes, then increased to 650°C for 10 minutes, and to 700°C for 10 minutes, and then increased to 800°C for 10 minutes and 900°C for 10 minutes. The material is then discharged and analyzed. The product is made of Al 3 A powder composed of Sc and a small amount of Sc. Figure 8 shows the XRD spectrum of the material, clearly showing that to correspond to the Al 3 The line of Sc is dominant.

Embodiment 2

[0138] Embodiment 2: produce Al 3 Sc powder

[0139] 4Al to 1ScCl 3 The molar ratio of 5g of Al powder with an average particle size of less than 15 microns to ScCl 3 Powder mix. The material is then placed in a quartz tube and heated at a temperature between room temperature and 900° C. and a pressure below 10 mbar. The temperature was raised in steps at 100° C. and the total heating time was 60 minutes. The material is then discharged and analyzed. The product is made of Al 3 Powder composed of Sc.

Embodiment 3

[0140] Embodiment 3: produce Al 3 (Sc-Zr powder)

[0141] 4Al to 0.5ScCl 3 and 0.5ZrCl 4 The molar ratio of 5g of Al powder with an average particle size of less than 15 microns to ScCl 3 Powder and ZrCl 4Powder mix. The material is then placed in a quartz tube and heated at a temperature between room temperature and 900° C. and a pressure below 10 mbar. The temperature was raised in steps at 100° C. and the total heating time was 60 minutes. The material is then discharged and analyzed. The product is made of Al 3 (Sc-Zr) powder composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com