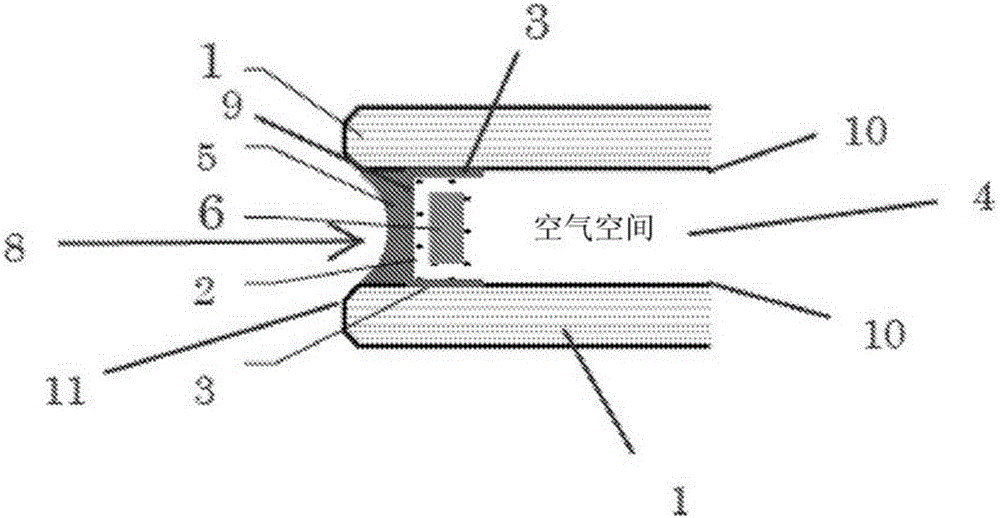

Polyurethane sealant based on poly (butylene oxide) polyols for glass sealing

A technology of butylene oxide and polyols, applied in polyurea/polyurethane adhesives, glass/slag layered products, adhesives, etc., can solve problems such as difficult mixing, increased viscosity, long mixing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

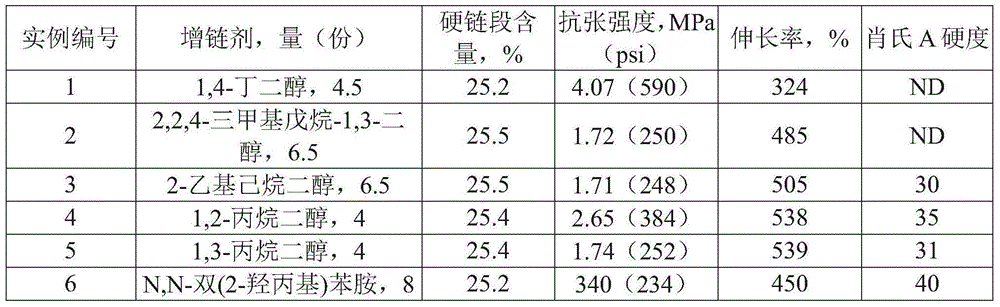

[0068] Example 1 was prepared by mixing 50 parts of a 2000 molecular weight bifunctional poly(1,2-butylene oxide) homopolymer with 50 parts of a 3000 molecular weight nominally trifunctional poly(1,2-propylene oxide) homopolymer Polyol blend. To this blend was added 4.5 parts 1,4-butanediol and about 0.04 parts tin catalyst. This blend was mixed with a 143 isocyanate equivalent weight "liquid" MDI product at an isocyanate index of 1.02 to form a reaction mixture. The resulting cured elastomer contained 25.2% hard segments. The reaction mixture was compression molded at 50° C. for 30 minutes under an applied pressure of 20,000 psi (about 140 MPa) for 30 minutes. Tensile strength and elongation were measured according to ASTM1708 and are reported in Table 1 below. The results are indicated in Table 1.

[0069] Examples 2-6 were prepared in the same manner except that in each case 1,4-butanediol was replaced by another chain extender (as indicated in Table 1). The amount of ...

example 7

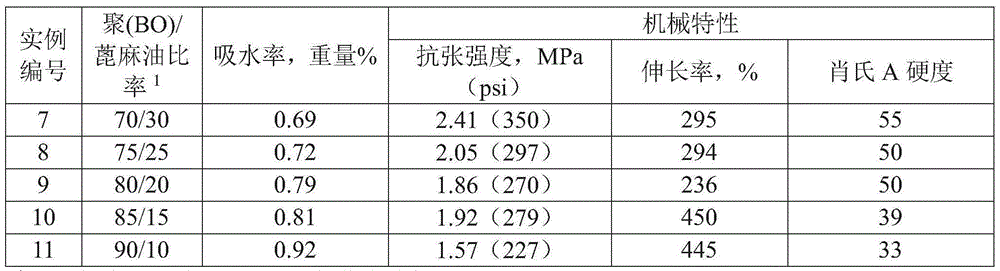

[0074] Example 7 was prepared by mixing 70 parts of a 2000 molecular weight bifunctional poly(1,2-butylene oxide) homopolymer with 30 parts of castor oil. To this blend was added 1.5 parts 1,4-butanediol and 0.04 parts tin catalyst. The amount of 1,4-butanediol is chosen such that when cured at an isocyanate index of 1.1, the resulting cured elastomer contains 25% hard segments. This mixture was then combined with a 143 isocyanate equivalent weight "liquid" MDI product at an isocyanate index of 1.1 to form a reaction mixture which cured as described for Examples 1-6. Tensile strength, elongation and Shore A hardness were measured as before and the results are indicated in Table 2 below.

[0075] Cured film samples were cut into dog bones to evaluate the effect of water immersion on mechanical properties. Determination of the initial weight of the film (W 0 ). In each case, the membranes were then immersed in deionized water maintained at 25°C for 24 hours or in boiling wat...

example 12

[0083] The sealant compositions were prepared and cured in the general manner described in the previous examples. The formulation is 85 parts of 2000 molecular weight bifunctional poly(1,2-butylene oxide) homopolymer, 15 parts of castor oil, 1.5 parts of 1,4 butanediol, 0.05 part of tin catalyst and 26.3 parts of 143 equivalent weight "liquid "MDI. The resulting elastomer was cured at 50°C for three days. Its tensile strength is about 200 MPa (290 psi) and its elongation is about 440. The water absorption was 0.8% by weight.

[0084]Moisture Vapor Transmission Rate (MVTR) was analyzed on a MOCONPermatran-W3 / 33 Water Vapor Permeability Instrument. Standards applied to instruments include ASTMF-1249, TAPPIT557 and JISK-7129. The moisture vapor transmission rate was 1.6 g / (100 in2 / day) (0.103 g / m2 / day).

[0085] Oxygen transmission rate (OTR) was analyzed on a MOCONOxtran2 / 21 instrument. Standards applied to instruments include ASTMD-3985, ASTMF-1927, DIN53380, JISK-7126 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com