Implementation method, application method and connection structure for welding tin-solderable conductor and tin-unsolderable matrix

A realization method and connection structure technology, applied in the direction of connection, welding equipment, connection contact materials, etc., can solve problems such as difficult to further improve production efficiency and labor costs, and achieve reduced surface treatment costs, high reliability, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Solderable Conductor and Non-Solderable Substrate Welding Realization Method

[0063] refer to Figure 1~4 , the solderable conductor of the present invention and the non-solderable substrate welding implementation method specifically include the following steps:

[0064] (1) Prepare the materials to be welded.

[0065] The materials to be soldered mainly refer to solderable conductors with solderable properties and non-solderable substrates without solderable properties.

[0066] The conductor referred to in this embodiment specifically refers to the outer conductor of the coaxial cable. Coaxial cables are usually used in the field of mobile communications, especially the connection between coaxial cables and radio frequency components of mobile communications to realize the conduction of signals based on electromagnetic waves. According to the application scenario, the components with specific functions connected to coaxial cables are is the corresponding substrate...

Embodiment 2

[0082] Connection structure between solderable conductor and non-solderable substrate

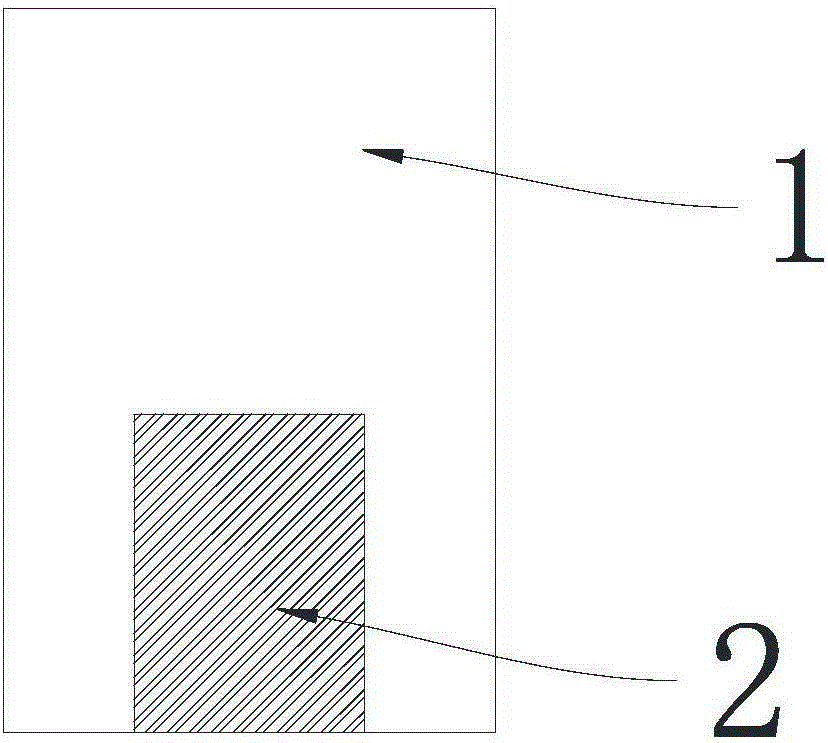

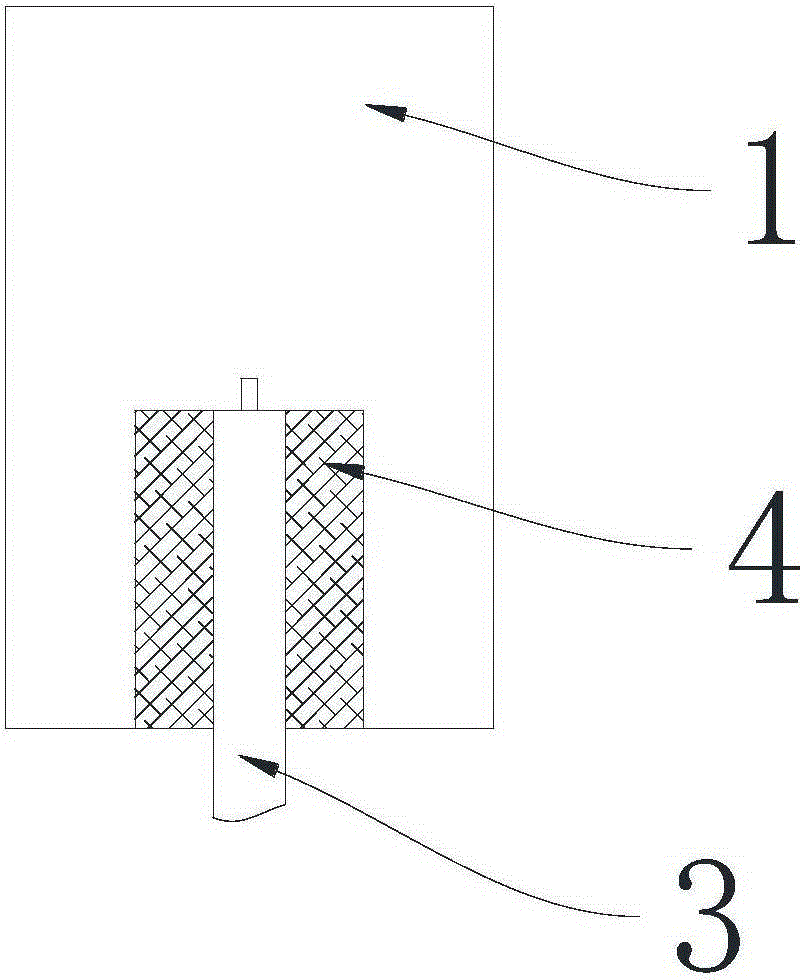

[0083] refer to Figure 4~6 , the welding point 11 is generally arranged at the intersection between the outer conductor (or inner conductor) of the coaxial cable 3 and the non-solderable substrate 1 .

[0084] Such as Figure 4 As shown, when the intersection is a plane, the metal layer 2 is sprayed within the range specified as the welding point 11, no matter whether the shape of the welding point 11 is regular or irregular, when the molten When the solder 4 is filled between the outer conductor of the coaxial cable 3 and the metal layer 2, the melted solder 4 will be on the outer conductor of the coaxial cable 3 and the metal layer 2 under the action of temperature field, gravity, etc. The gaps and spaces between are automatically distributed, and after the solder 4 is cooled and condensed, it will form as Figure 4 solder layer shown.

[0085] In order to facilitate the positioning ...

Embodiment 3

[0088] Connection structure of communication device and coaxial cable

[0089] The coaxial cable 3 usually needs to be electrically connected to the electrical components in the communication device, which requires the communication device to provide a metal base for electrical connection. In some cases, the metal base has a non-solderable Therefore, the connection between the communication device and the coaxial cable needs to be realized by the welding method of the above-mentioned solderable conductor and the non-solderable substrate, and the solderable conductor and the non-solderable substrate formed by this welding method have the above-mentioned connection structure.

[0090] If the communication device is an electrical component with complete functions, the metal base is provided by the electrical component, and the electrical component includes two parts: one is the first part for forming the metal layer, and the coaxial The outer conductor of the cable is welded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com