Industrialized test method for PTT/PET self-crimping filament elasticity

A self-curling yarn and self-crimping technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials and the preparation of test samples, can solve the problem of sticking, inconvenient operation of single multifilament dry heat treatment, and large test volume and other problems, to achieve the effect of improving the accuracy of the experiment, saving the cost and time of the experiment, and reducing the number of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Raw material: PTT / PET self-crimping filament, linear density 166.7dtex, number of filaments 64, component ratio 50 / 50.

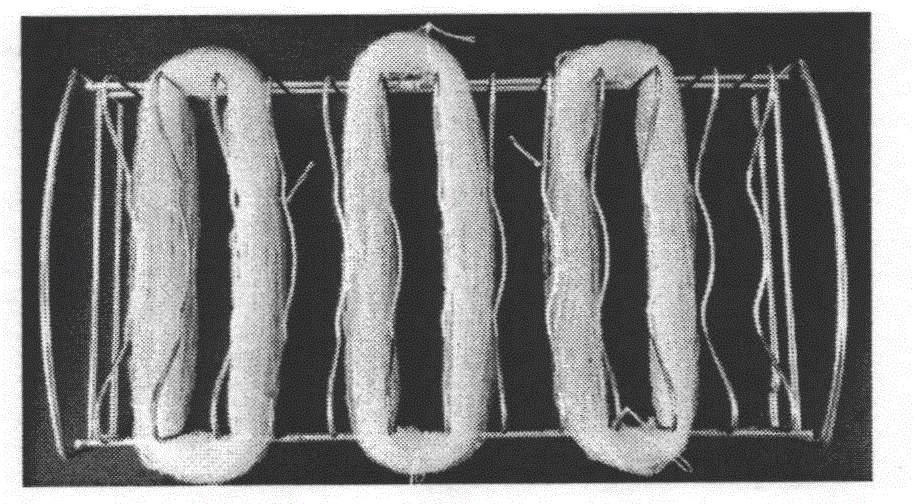

[0055] (1) Wind the PTT / PET self-crimping filament into skeins by using the YG086C skein length measuring machine. 100cm. 10 bobbins are randomly selected from each batch of samples, and each bobbin is wound with 1 skein.

[0056] (2) Carry out dry heat treatment to the skein, the dry heat treatment process is: constant temperature treatment at 120° C. for 8 minutes.

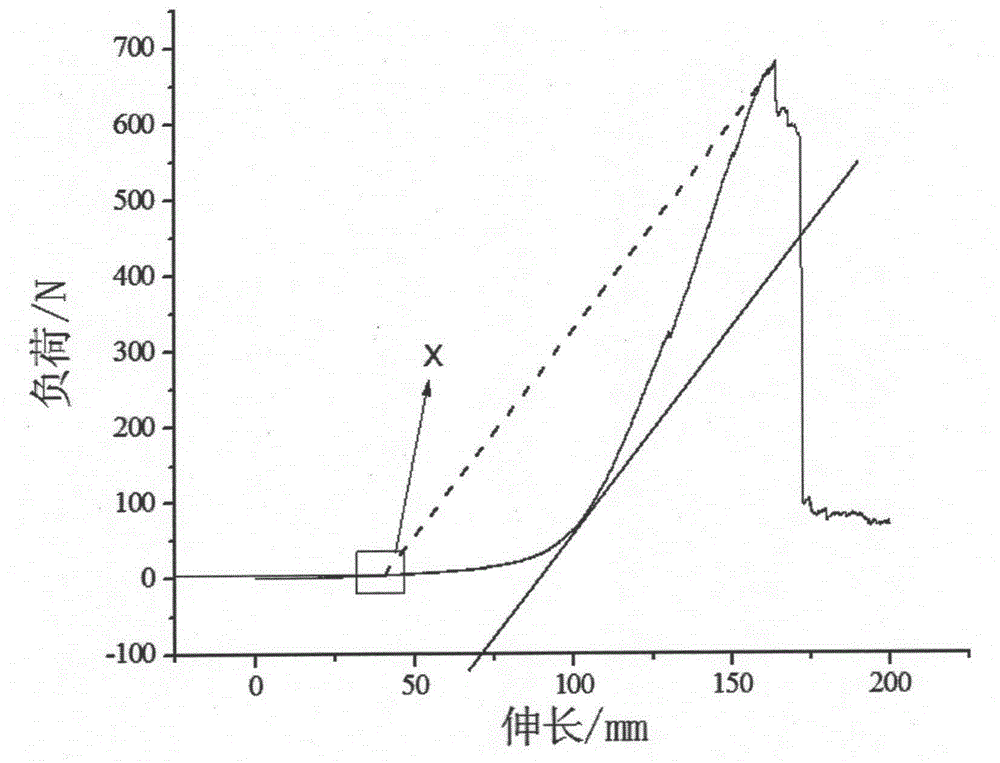

[0057] (3) Carry out tensile test to the skein sample after heat treatment with a special skein stretching column, and the test obtains the load-elongation curve of the skein, see Figure 5 , Test conditions: clamping distance 100mm, tensile speed 100mm / min.

[0058] (4) On the tensile curve of the skein, take the stress 0.01cN / dtex as the starting point of the elastic elongation of the skein, and make a straight line parallel to the starting point and the breaking point of the skein...

Embodiment 2

[0061] Raw material: PTT / PET self-crimping filament, linear density 166.7dtex, number of filaments 48, component ratio 50 / 50.

[0062] Referring to Example 1, PTT / PET self-crimping filaments were made into skeins, heat treated and tensile tested.

[0063] The average value of elastic elongation of PTT / PET self-crimping skein is 65.91%, and the coefficient of variation is 4.70%.

Embodiment 3

[0065] Raw material: PTT / PET self-crimping filament, linear density 166.7dtex, number of filaments 72, component ratio 40 / 60.

[0066] Referring to Example 1, PTT / PET self-crimping filaments were made into skeins, heat treated and tensile tested.

[0067] The average value of elastic elongation of PTT / PET self-crimping skein is 60.72%, and the coefficient of variation is 2.45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| coefficient of variation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com