Solvent-free polyurethane resin and preparation method and application thereof

A solvent-free polyurethane and polyurethane resin technology, applied in the field of polyurethane, can solve the problems of flat and stiff leather feel, insufficient lubrication between molecular chains, etc., to improve material compatibility, soft and plump hand feel, and delicate crease. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

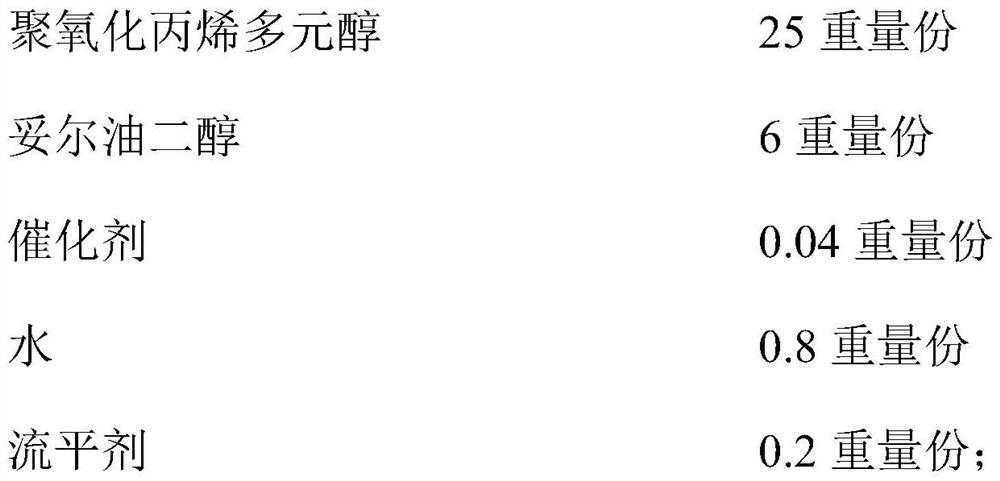

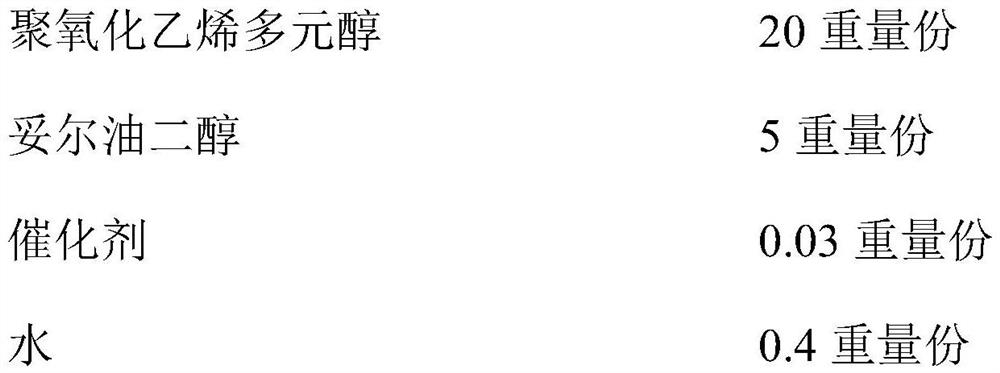

Method used

Image

Examples

preparation example 1

[0068] A kind of tall oil diol, its preparation method comprises the steps:

[0069] (1) Tall oil and thionyl chloride were reacted at 80° C. for 5 h, separated and purified to obtain tall oil chloride; the molar ratio of carboxyl in the thionyl chloride to tall oil was 2.5:1

[0070] (2) The tall oil chloride obtained in step (1) is slowly added dropwise in the DMF solution of dopamine under ice bath conditions (the mol ratio of the acid chloride group in dopamine and tall oil chloride is 1.1:1), and the dropwise addition ends Afterwards, continue mixing in the ice bath for 30 min, remove the ice bath, and react at 80° C. for 4 h to obtain the tall oil diol.

preparation example 2

[0072] A kind of tall oil diol, its preparation method comprises the steps:

[0073] (1) Tall oil and thionyl chloride were reacted at 70° C. for 6 h, separated and purified to obtain tall oil chloride; the molar ratio of the carboxyl groups in the thionyl chloride to tall oil was 3:1

[0074] (2) The tall oil acid chloride obtained in step (1) is slowly added dropwise in the DMF solution of dopamine under ice bath conditions (the mol ratio of the acid chloride group in dopamine and tall oil acid chloride is 1.2:1), and the dropwise addition ends Afterwards, continue mixing in the ice bath for 30 min, remove the ice bath, and react at 70° C. for 5 h to obtain the tall oil diol.

preparation example 3

[0076] A kind of tall oil diol, its preparation method comprises the steps:

[0077] (1) Tall oil and thionyl chloride were reacted at 100° C. for 4 h, separated and purified to obtain tall oil chloride; the molar ratio of the carboxyl groups in the thionyl chloride to tall oil was 2:1

[0078] (2) The tall oil acid chloride obtained in step (1) is slowly added dropwise in the DMF solution of dopamine under ice bath conditions (the mol ratio of the acid chloride group in dopamine and tall oil acid chloride is 1:1), and the addition ends Afterwards, continue mixing in the ice bath for 30 min, remove the ice bath, and react at 90° C. for 3 h to obtain the tall oil diol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com