Soft polyester cotton down-proof fabrics and processing method thereof

A technology for feather-proof fabrics and processing methods, which can be applied to fabric surface trimming, fabrics, and textiles, etc., which can solve the problems of high fabric cost, long floating length, thick fabric feel, etc., achieve good feather-proof durability, improve warmth retention, The effect of fabric structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

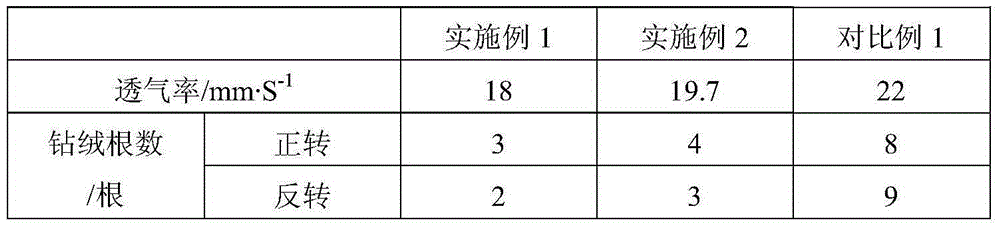

Embodiment 1

[0033] The warp yarn of the fabric is 50D / 96F polyester DTY, the polyester single fiber fineness is 0.5D, the weft direction is polyester-cotton blended 60S, and the polyester fiber accounts for 80% of the yarn mass. The fabric specification is 105 / polyester 50D*60S (polyester / cotton 80 / 20) / 182*115, the fabric weave is plain weave, the covering tightness in warp direction is 63%, and the covering tightness in weft direction is 52%.

[0034] The fabric processing process is: winding → warping → sizing → drawing and reeding → weaving → gray fabric singeing → desizing, scouring, bleaching → sanding → tentering → calendering → preshrinking.

[0035] Sizing mainly adopts soluble polyester size, antistatic agent and defoamer. Among them, 70kg of soluble polyester slurry, 2kg of antistatic agent, and 2kg of defoamer.

[0036] Warping: The warping machine adopts Benninger high-speed warping machine, the warping speed is 900m / min, and the position of the tension bar is 0mm.

[0037] ...

Embodiment 2

[0045] The warp yarn of the fabric is 75D / 144F polyester DTY, the polyester single fiber fineness is 0.5D, and the weft direction is polyester-cotton blended 40S, in which the polyester fiber accounts for 50% of the yarn mass. The fabric specification is 105 / polyester 75D*40S (polyester / cotton 50 / 50) / 145*100, the fabric weave is plain weave, the warp direction cover tightness is 61%, and the weft direction cover tightness is 56%.

[0046] Fabric processing process is: winding → warping → sizing → drawing and reeding → weaving → gray fabric singeing → desizing, scouring, bleaching → sanding → tenter setting → calendering → preshrinking.

[0047] Sizing mainly adopts soluble polyester size, antistatic agent and defoamer. Among them, the soluble polyester slurry is 75kg, the antistatic agent is 3kg, and the defoamer is 3kg. When the soluble polyester size is used for desizing under alkaline conditions, the size is easily removed and the fabric feels better.

[0048] Warping: Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com