A positive electrode grid alloy for maintenance-free lead-acid batteries

A technology of lead-acid battery and positive plate, applied in the direction of electrode carrier/collector, etc., to achieve the effect of preventing floating, uniform distribution, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

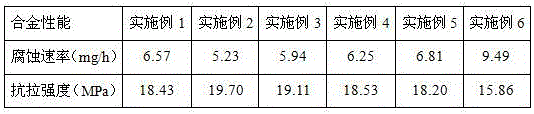

Examples

Embodiment 1

[0037] A positive grid alloy for a maintenance-free lead-acid battery, comprising the following components in weight percentages:

[0038] Barium 0.02%,

[0039] Silver 0.002%,

[0040] Calcium 0.04%,

[0041] Tin 0.25%,

[0042] Lanthanum 0.02%,

[0043] lead balance;

[0044] According to the proportioning of above-mentioned grid alloy, make following preparation:

[0045] (1) Divide the lead into two parts, one part is melted at 410-440°C, and the other part is used; after the lead is melted, add tin; after it is completely melted, heat up to 1500-1600°C, and add calcium; After melting, stir evenly; when the temperature drops to 500-550°C, take it out of the furnace to obtain lead-tin-calcium alloy;

[0046] (2) Melt rare earth elements in a high-temperature furnace at 950°C. After complete melting, heat up to 1000-1100°C, then add silver, and stir evenly after it is completely melted; when it drops to 400-450°C, take it out of the furnace to obtain Silver rare earth...

Embodiment 2

[0050] A positive grid alloy for a maintenance-free lead-acid battery, comprising the following components in weight percentages:

[0051] Barium 0.05%,

[0052] Silver 0.003%,

[0053] Calcium 0.08%,

[0054] Tin 0.95%,

[0055] Praseodymium 0.02%,

[0056] Neodymium 0.04%,

[0057] lead balance;

[0058] According to the proportioning of above-mentioned grid alloy, make following preparation:

[0059] (1) Divide the lead into two parts, one part is melted at 410-440°C, and the other part is used; after the lead is melted, add tin; after it is completely melted, heat up to 1500-1600°C, and add calcium; After melting, stir evenly; when the temperature drops to 500-550°C, take it out of the furnace to obtain lead-tin-calcium alloy;

[0060] (2) Melt rare earth elements in a high-temperature furnace at 950°C. After complete melting, heat up to 1000-1100°C, then add silver, and stir evenly after it is completely melted; when it drops to 400-450°C, take it out of the furnace ...

Embodiment 3

[0064] A positive grid alloy for a maintenance-free lead-acid battery, comprising the following components in weight percentages:

[0065] Barium 0.05%,

[0066] Silver 0.003%,

[0067] Calcium 0.08%,

[0068] Tin 0.95%,

[0069] Praseodymium 0.04%,

[0070] Neodymium 0.02%,

[0071] lead balance;

[0072] According to the proportioning of above-mentioned grid alloy, make following preparation:

[0073] (1) Divide the lead into two parts, one part is melted at 410-440°C, and the other part is used; after the lead is melted, add tin; after it is completely melted, heat up to 1500-1600°C, and add calcium; After melting, stir evenly; when the temperature drops to 500-550°C, take it out of the furnace to obtain lead-tin-calcium alloy;

[0074] (2) Melt rare earth elements in a high-temperature furnace at 950°C. After complete melting, heat up to 1000-1100°C, then add silver, and stir evenly after it is completely melted; when it drops to 400-450°C, take it out of the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com