Cr4Mo4V steel bearing powerful shot blasting and heating injection/permeation composite surface strengthening method

A composite surface and shot peening technology, which is applied in the direction of ion implantation plating, coating, metal material coating technology, etc., to achieve the effect of improving fatigue life, improving surface hardness and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

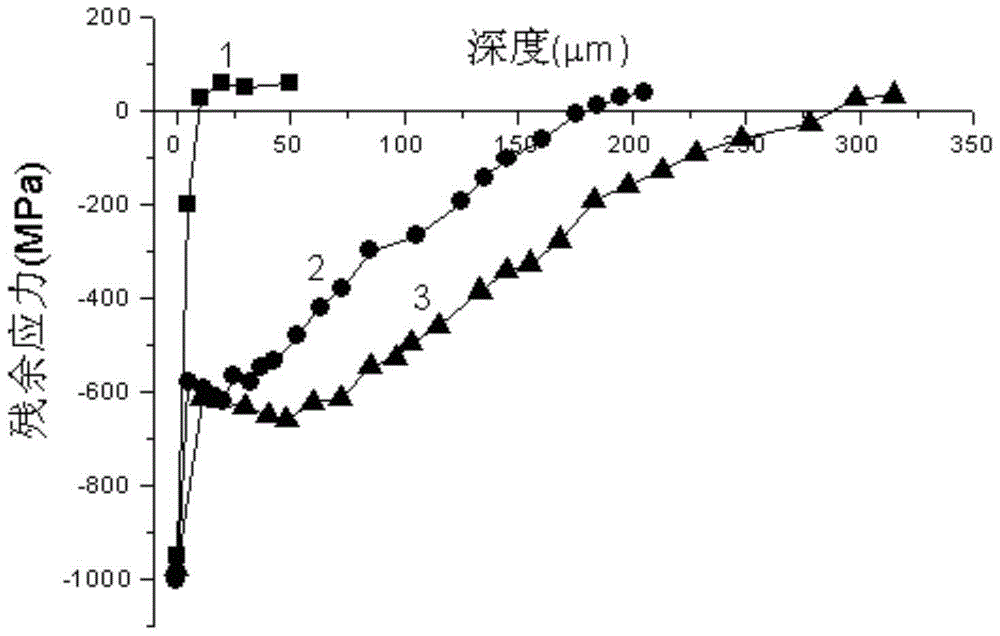

[0023] Specific implementation mode one: this implementation mode is a composite surface strengthening method of Cr4Mo4V steel bearing strong shot peening and temperature rise injection infiltration, which is completed as follows:

[0024] 1. Powerful shot peening: The Cr4Mo4V steel bearing raceway is treated with a strong shot peening process, and a deformation strengthening layer with a thickness of 500 μm to 700 μm is formed on the surface of the Cr4Mo4V steel bearing raceway;

[0025] The instrument used in the powerful shot peening process is a mechanical centrifugal shot peening machine. The centrifugal speed of the mechanical centrifugal shot peening machine is 2000r / min~5000r / min. The material of the shot is reinforced steel shot, and the microhardness of the shot is HRC58~ HRC63, the diameter is 1mm~2mm, the distance from the nozzle to the Cr4Mo4V steel shaft is 300mm~500mm, the shot peening flow rate is 50kg / min~200kg / min, the shot peening speed is 100m / s~200m / s, and ...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the Cr4Mo4V steel bearing raceway is treated with a powerful shot peening process, and a deformation strengthening layer with a thickness of 600 μm is formed on the surface of the Cr4Mo4V steel bearing raceway. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the instrument used in the powerful shot peening process described in step one is a mechanical centrifugal shot blasting machine, and the centrifugal force of the mechanical centrifugal shot blasting machine is The speed is 3000r / min, the projectile material is reinforced steel shot, the microhardness of the projectile is HRC58~HRC63, the diameter is 1.2mm, the distance from the nozzle to the Cr4Mo4V steel shaft is 400mm, the shot peening flow rate is 100kg / min, and the shot peening speed is 150m / s, the shot peening time is 3min, the spray angle is θ=50°, and the surface coverage is 100%. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com