Screw air compressor oil composition and preparation method thereof

An air compressor oil and screw type technology, which is applied in the direction of lubricating compositions, etc., can solve the problems of air compressor components such as corrosion, increased kinematic viscosity and acid value, harsh working conditions, etc. Viscosity and acid value change is small, the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a kind of preparation method of screw air compressor oil composition, comprises the following steps:

[0064] Mixing synthetic hydrocarbon base oil, synthetic ester base oil and functional additives to obtain screw air compressor oil, the temperature of the mixing is 60°C to 80°C; the functional additives include antiwear agents and metal deactivators , Antirust agent, antioxidant, pour point depressant, antiemulsifier, antifoam agent and acid scavenger.

[0065] In the present invention, the synthetic hydrocarbon base oil, synthetic ester base oil and functional additives are firstly mixed, wherein the present invention has no special restrictions on the mixing method and mixing order, and can be mixed according to the following method:

[0066] After mixing the synthetic hydrocarbon base oil and the synthetic ester base oil, heating and dehydrating, the temperature is lowered to 60-80°C, and then functional additives are added, mixe...

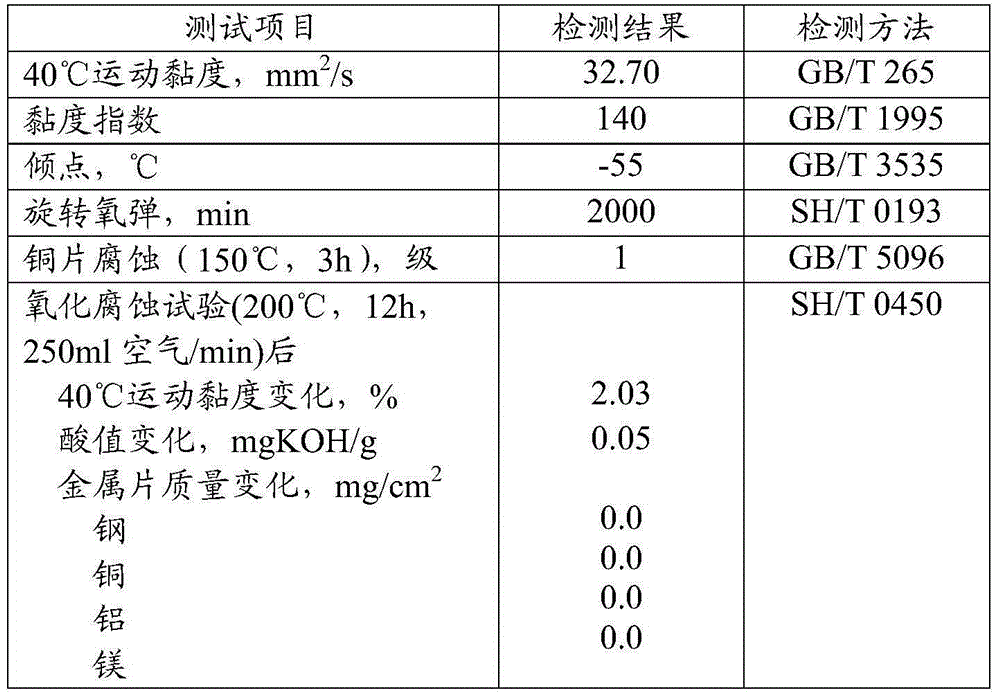

Embodiment 1

[0076] 1mol sebacic acid (purchased from Tongliao Xinghe Biotechnology Co., Ltd.), 2.6mol of isotridecanol (purchased from Foshan Kaizhou Chemical Co., Ltd.) and 1.5g p-toluenesulfonic acid (purchased from Sanyuan Chemical Trading Co., Ltd.) After the catalyst is mixed evenly, heat to 190°C for esterification reaction. After 4 hours of reaction, distill off excess acid under reduced pressure to obtain crude ester. After cooling down to 60°C, carry out alkali washing, water washing, dehydration and drying, and filter to obtain the base Oil.

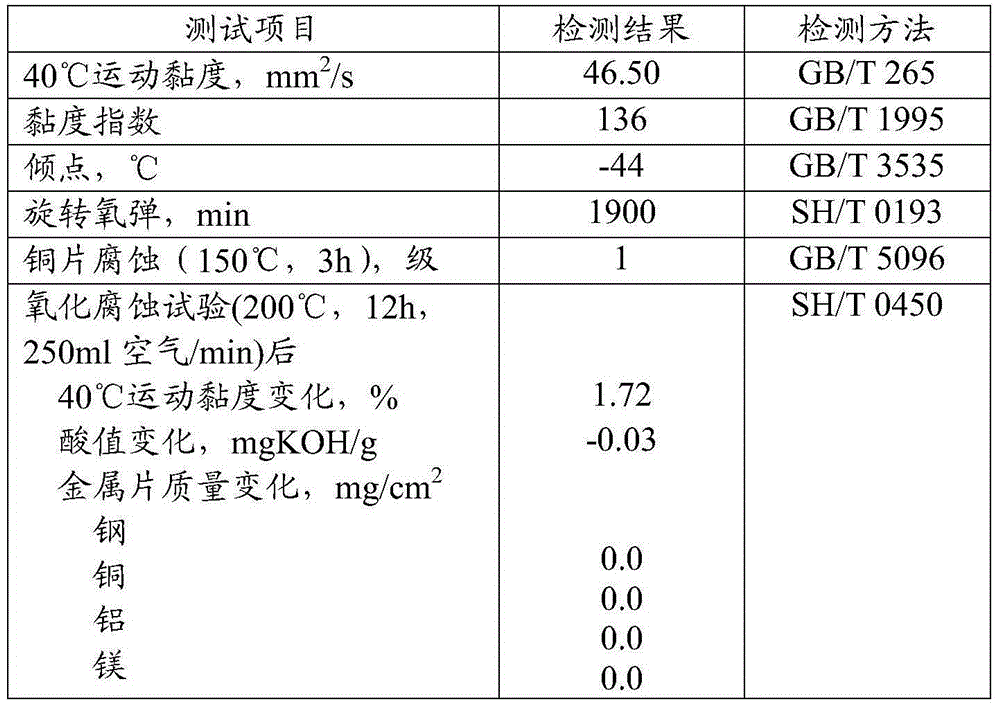

Embodiment 2

[0078] 1mol phthalic acid (purchased from Tongliao Xinghe Biotechnology Co., Ltd.), 2.6mol of isotridecanol (purchased from Foshan Kaizhou Chemical Co., Ltd.) and 1.5g p-toluenesulfonic acid (purchased from Sanyuan Chemical Trade Co., Ltd. ) after the catalyst is mixed evenly, heated to 190°C for esterification reaction, after 4 hours of reaction, the excess acid was distilled off under reduced pressure to obtain the crude ester, after cooling down to 60°C, it was washed with alkali and water, then dehydrated and dried, and filtered to obtain base oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com