Gasifier and method for conducting gasification treatment on carbon-bearing raw materials

A technology for gasifier and raw materials, which is applied in the direction of granular/powder fuel gasification, molten salt/molten metal gasification, etc., can solve problems such as restricting the application of gasifier, and achieve the elimination of air separation system and gas production performance. High, good material transfer properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

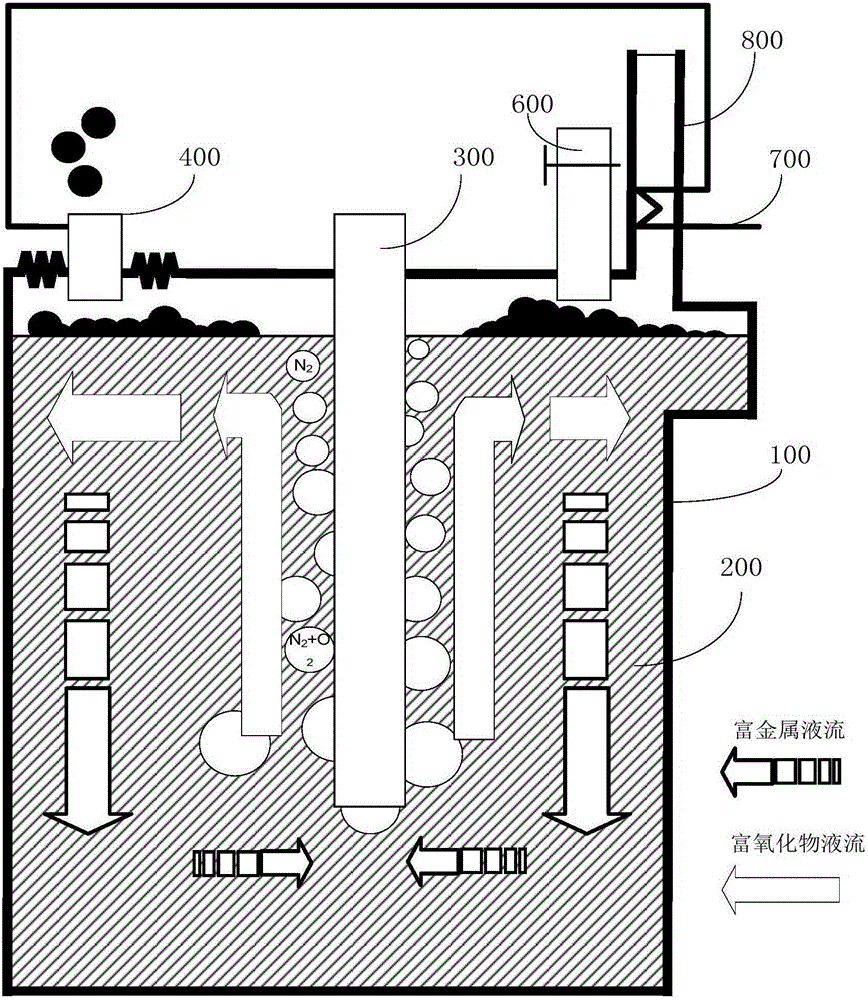

[0073] In this example, a double-chamber liquid metal gasifier is used, copper is used as the metal medium, biomass is used as the raw material, carbon dioxide and water vapor with a volume ratio of 1:1 are used as the gasification agent, and limestone is used as the slagging agent. Preparation of synthesis gas, wherein, the schematic diagram of the structure of the gasifier is as follows figure 2 Shown, preparation method is specifically as follows:

[0074] (1) The molten pool 200 is used to smelt copper to obtain molten copper.

[0075] (2) Utilize the air pipeline 300 to supply air to the oxidation zone, and oxidize the molten copper in the oxidation zone through the air to obtain molten copper oxide, and the remaining nitrogen gas is discharged from the nitrogen gas outlet 900 .

[0076] (3) Molten copper oxide enters the gasification zone and the slagging zone from the oxidation zone through the through hole 520, and the molten copper enters the oxidation zone from the...

Embodiment 2

[0082] In this example, a liquid metal gasification furnace is used, copper-zinc alloy is used as the metal medium, graphite is used as the raw material, carbon dioxide and water vapor with a volume ratio of 2:1 are used as the gasification agent, and bauxite is used as the slagging agent. Preparation of synthesis gas, wherein, the schematic diagram of the structure of the gasifier is as follows figure 1 As shown, the molten pool 200 is a deep metal molten pool, and the air pipeline 300 is extended to the bottom of the deep metal molten pool. After the molten pool is deepened, the oxygen in the air can fully react with the liquid metal, and the gaseous oxygen and carbon raw materials are isolated. The contact between the carbon raw material gasification intermediate product and the product gas ensures the safe operation of the gasifier. The method of using the gasifier to prepare synthesis gas is as follows:

[0083] (1) The copper-zinc alloy is smelted by using the melting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com