Closed coke quenching and heat energy recycling method and device

A closed-type technology for recovering heat energy, applied in the cooling of coke, coke oven, waste heat treatment, etc. It can solve the problems of restricting the widespread popularization of CDQ technology, heavy cost burden, high equipment investment and operating cost, and achieve coke quenching time. The effect of short, reduced equipment cost and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

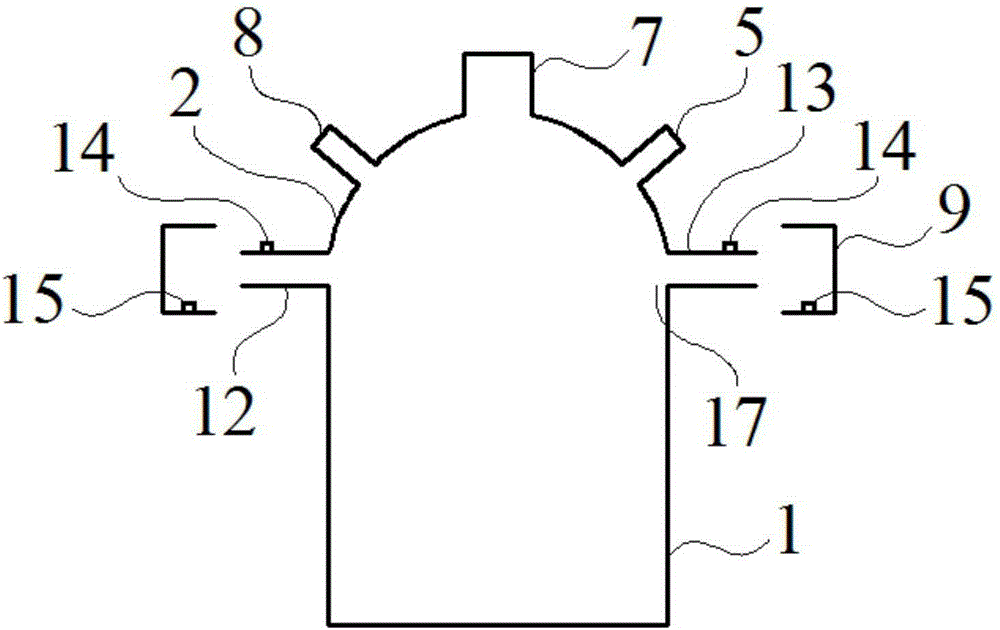

[0031] This embodiment is a coke quenching process scheme for airtight water spraying vaporization cooling, the system is as follows figure 1 shown. After the red coke is loaded into the coke drum 1, it is moved to the top airtight cover in the coke quenching tower (not shown in the figure) by the moving car 3, the top airtight cover 2 is lowered, and the outer edge sealing rings 9 are closed from both sides to complete The sealing of the coke tank. After opening the specific valve in the steam outlet pipe control valve 10, spray water to the red coke (not shown in the figure) in the coke tank through the top sealing cover water spray pipe 5 according to the flow rate calculated in advance, and the injected water vaporizes to produce The steam enters the steam storage tank 11 through the steam outlet pipe 7 . After spraying water at the top to a certain hour, stop the top water spraying and start to spray water from the bottom water spray pipe 6 . The water sprayed into the...

Embodiment 2

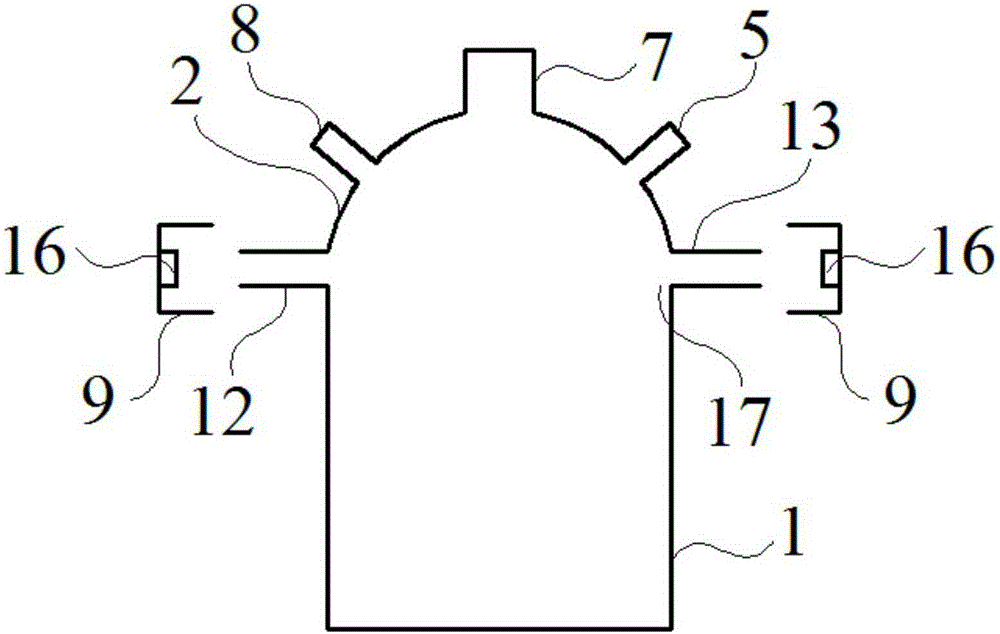

[0033] This embodiment is basically the same as Embodiment 1, except that the steam pressure in the coke tank is controlled at a gauge pressure of 0.40-0.45 MPa. The sealing ring in the outer edge sealing ring 9 adopts the mode arranged on the inner ring side of the outer edge sealing ring, such as image 3 The seal ring 16 on the inner ring side of the middle and outer edge seal ring is shown. The coke can overturning mechanism 4 is arranged on the coke unloading platform, and the mobile car 3 moves to the side of the overturning mechanism to overturn the coke can. After spraying water at the top to a certain hour, stop the top water spraying and start to spray water from the bottom water spray pipe 6 . The water sprayed into the coke tank from the top is steam condensed water, and the water sprayed into the coke tank from the bottom is residual ammonia water, sprayed until the coke temperature is 500-600 ° C, and then sprayed with steam condensed water. All water is heated...

Embodiment 3

[0035] This embodiment is basically the same as Embodiment 1, except that the sealing ring in the outer edge sealing ring 9 is arranged on the inner ring side of the outer edge sealing ring, and on the inner side of the lower part of the outer edge sealing ring and on the upper part of the protruding edge of the top airtight cover With the hybrid sealing method, the steam pressure in the coke tank is controlled at a gauge pressure of 0.55-0.60MPa. In addition, the water sprayed into the coke drum from the top is steam condensed water, and the water sprayed into the coke drum from the bottom is the mixed water of residual ammonia water and condensed water, sprayed until the coke temperature is below 500°C, and then sprayed with steam condensed water to the coke drum When the temperature of the coke in the furnace drops to 150°C, stop spraying water to complete the cooling of the coke and enter the coke unloading process. The pressure relief of the coke tank is realized through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com