Heat-resisting antibacterial thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of thermoplastic elastomers, can solve the problems of TPU's poor antibacterial performance, affecting performance, and endangering health, achieving high bacterial killing rate, improving heat resistance, and good long-term performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

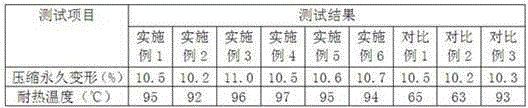

Examples

Embodiment 1

[0040] A heat-resistant and antibacterial thermoplastic polyurethane elastomer, the basic formula and weight ratio are: 40% polyester thermoplastic polyurethane, 10% polyphenylene ether, 5% chitin, 15% random copolymer polypropylene, saturated linear paraffin oil 28.5%, nano talc powder 1%, compound antioxidant 0.4%, EBS 0.1%.

[0041] The preparation technology of embodiment 1:

[0042] (1) Weigh the raw materials in the formula according to the weight ratio, add polyester thermoplastic polyurethane, polyphenylene ether, and random copolymerized polypropylene into the high mixer, stir for 1 hour, and mix well;

[0043] (2) Put the remaining other raw materials into the high mixer together with the raw materials mixed in step (1), stir for 10 minutes, and mix well;

[0044] (3) Put the raw materials mixed in step (2) into the hopper of the twin-screw extruder, melt and extrude, and granulate; the processing technology is as follows: set the temperature of the first zone of th...

Embodiment 2

[0046] A heat-resistant and antibacterial thermoplastic polyurethane elastomer, the basic formula and weight ratio are: polyether thermoplastic polyurethane 25%, polyphenylene sulfide 16%, silver-loaded antibacterial agent 12%, homopolypropylene 17%, naphthenic oil 20%, nano talc powder 5%, composite antioxidant 3%, silicone 2%.

[0047] The preparation technology of embodiment 2:

[0048] (1) Weigh the raw materials in the formula according to the weight ratio, add polyether thermoplastic polyurethane, polyphenylene sulfide, and homopolypropylene into the high mixer, stir for 2 hours, and mix well;

[0049] (2) Put the remaining other raw materials into the high mixer together with the raw materials mixed in step (1), stir for 40 minutes, and mix well;

[0050] (3) Put the raw materials mixed in step (2) into the hopper of the twin-screw extruder, melt and extrude, and granulate; the processing technology is as follows: set the temperature of the first zone of the twin-screw...

Embodiment 3

[0052] A heat-resistant and antibacterial thermoplastic polyurethane elastomer, the basic formula and weight ratio are: polyester thermoplastic polyurethane 32%, polyimide 20%, chitosan 5%, high-density polyethylene 15%, saturated linear alkanes Oil 25%, nano talc powder 1.5%, compound antioxidant 1%, erucamide 0.5%.

[0053] The preparation technology of embodiment 3:

[0054] (1) Weigh the raw materials in the formula according to the weight ratio, add polyester thermoplastic polyurethane, polyimide, and high-density polyethylene into the high-density mixer, stir for 1.5 hours, and mix well;

[0055] (2) Add the remaining other raw materials together with the raw materials mixed in step (1) into the high mixer, stir for 25 minutes, and mix well;

[0056] (3) Put the raw materials mixed in step (2) into the hopper of the twin-screw extruder, melt and extrude, and granulate; the processing technology is as follows: set the temperature of the first zone of the twin-screw extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com