Method for extracting natural preservative from bamboo leaves

A technology of natural preservatives and bamboo leaves, which is applied in the field of extracting active natural preservatives from bamboo leaves to achieve the effect of high extraction efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

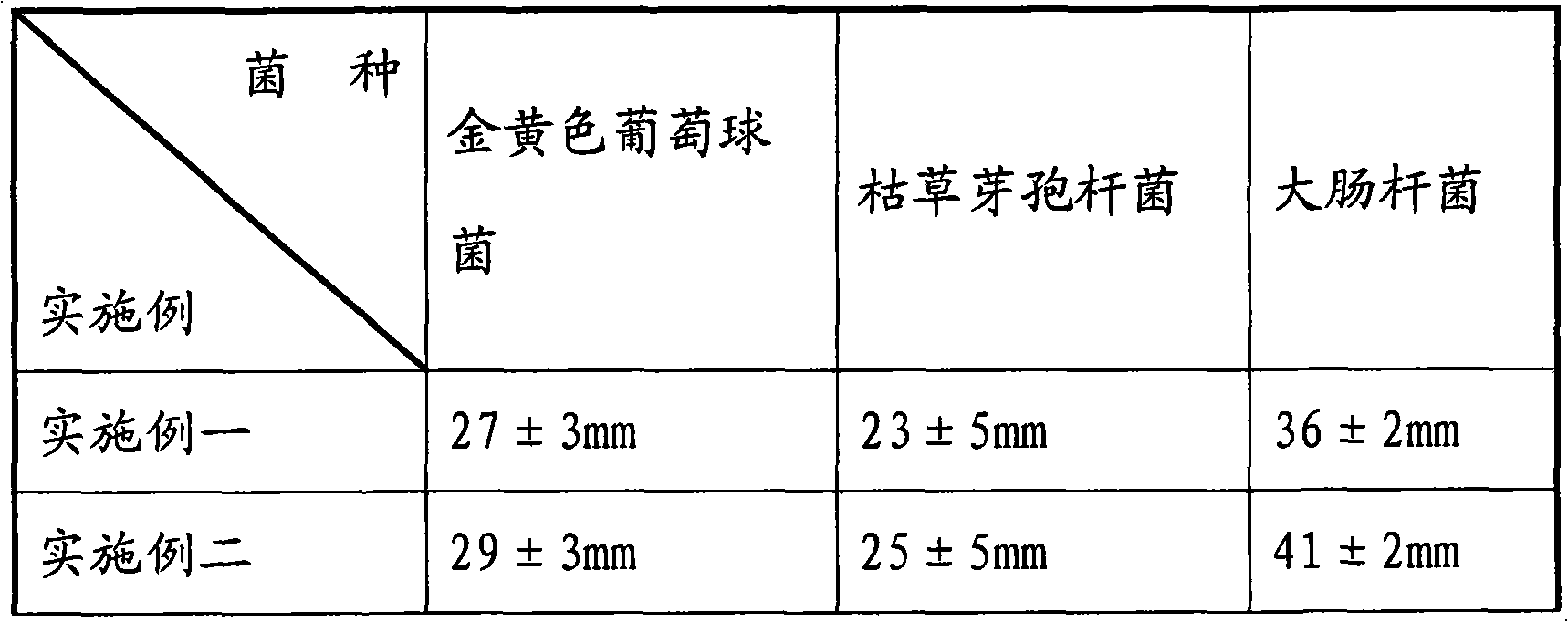

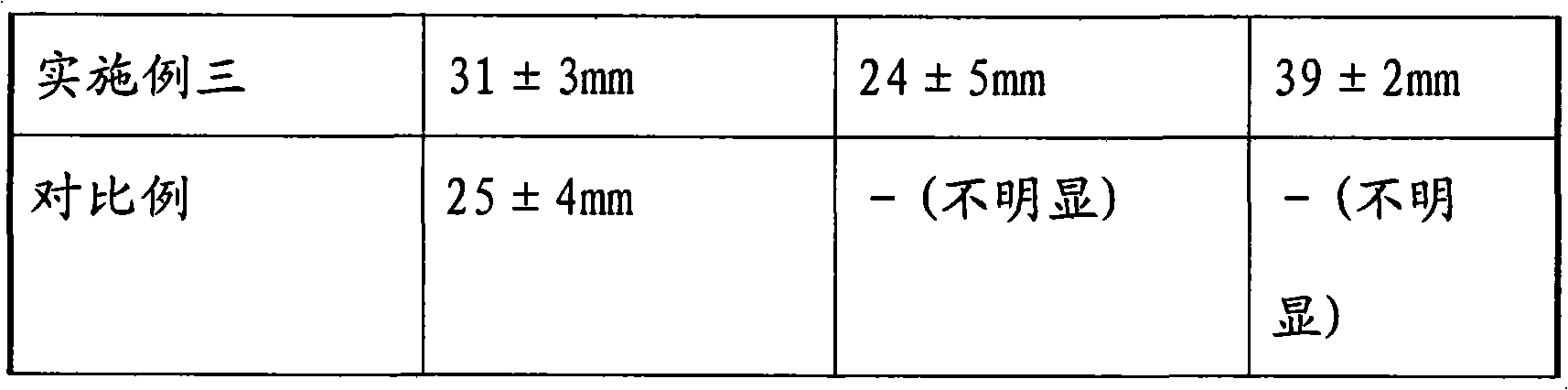

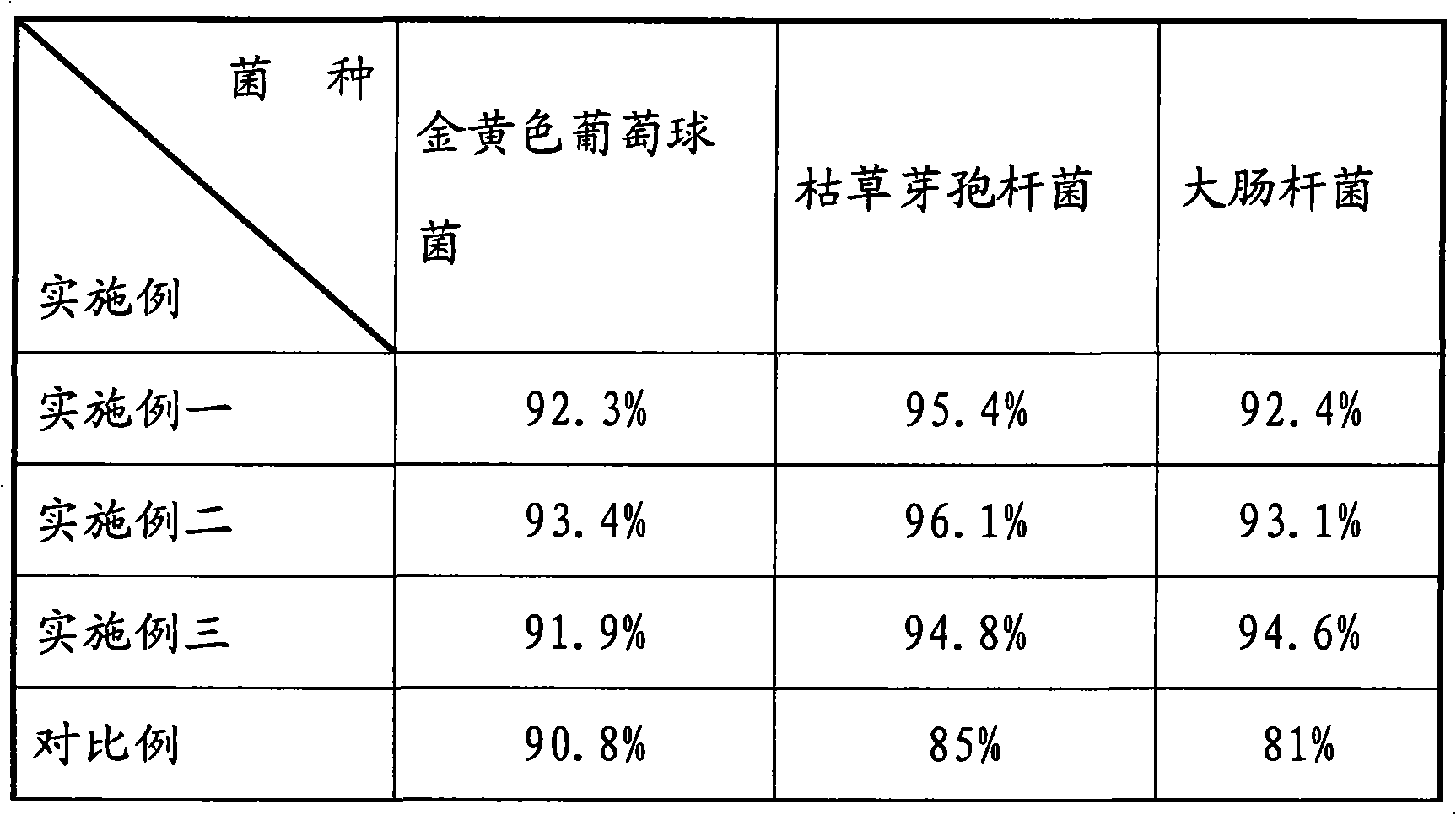

Examples

Embodiment 1

[0041] By the technological process shown in Fig. 1, the method for extracting natural antiseptic from bamboo leaf, comprises the following steps:

[0042] 1) Collect fresh bamboo leaves, wash and dry them for later use;

[0043] 2) Put 300kg of bamboo leaves into an extraction tank, add 30000ml of ethanol with a volume fraction of 60%, heat to 60°C, and assist 0.5 hours with ultrasonic waves with a frequency of 50KHz, then extract for 1.5 hours to make the active ingredients in the bamboo leaves fully Dissolve in ethanol solution, filter out the solution for later use;

[0044] 3) passing the above solution through a microporous filter device with a filtration accuracy of 0.5 μm to remove large particles of impurities to obtain a clarified filtrate;

[0045] 4) The above-mentioned filtrate is processed through a 2.5-inch tubular nanofiltration membrane module system made of polyamide, with a molecular weight cut-off of 300Da, an operating temperature below 30°C, a pressure o...

Embodiment 2

[0051] By the technological process shown in Fig. 1, the method for extracting natural antiseptic from bamboo leaf, comprises the following steps:

[0052] 1) Collect fresh bamboo leaves, wash and dry them for later use;

[0053] 2) Put 300kg of bamboo leaves into the extraction tank, add 21000ml of ethanol with a volume fraction of 60%, heat to 60°C, and use ultrasonic waves with a frequency of 100KHz for 0.75 hours, then extract for 2.0 hours, so that the active ingredients in the bamboo leaves are fully Dissolve in ethanol solution, filter out the solution for later use;

[0054] 3) passing the above solution through a microporous filter device with a filtration accuracy of 0.5 μm to remove large particles of impurities to obtain a clarified filtrate;

[0055] 4) The above-mentioned filtrate is treated by a 2.5-inch tubular nanofiltration membrane module system made of polyamide, with a molecular weight cut-off of 400Da, an operating temperature below 30°C, a pressure of 0...

Embodiment 3

[0061] By the technological process shown in Fig. 1, the method for extracting natural antiseptic from bamboo leaf, comprises the following steps:

[0062] 1) Collect fresh bamboo leaves, wash and dry them for later use;

[0063] 2) Put 300kg of bamboo leaves into the extraction tank, add 24000ml of ethanol with a volume fraction of 60%, heat to 60°C, and assisted with ultrasonic waves with a frequency of 120KHz for 1 hour, then extract for 0.75 hours to make the active ingredients in the bamboo leaves fully Dissolve in ethanol solution, filter out the solution for later use;

[0064] 3) passing the above solution through a microporous filter device with a filtration accuracy of 0.5 μm to remove large particles of impurities to obtain a clarified filtrate;

[0065] 4) The above-mentioned filtrate is treated by a 2.5-inch tubular nanofiltration membrane module system made of polyamide, with a molecular weight cut-off of 500Da, an operating temperature below 30°C, a pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com