Water-retaining high-molecular slow-release nitrogen-potassium fertilizer and preparation method thereof

A high-molecular, water-retaining technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of backwardness in the research field of water-retaining slow-release fertilizers, achieve excellent nutrient slow and controlled release performance, raw materials are cheap and easy to obtain, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

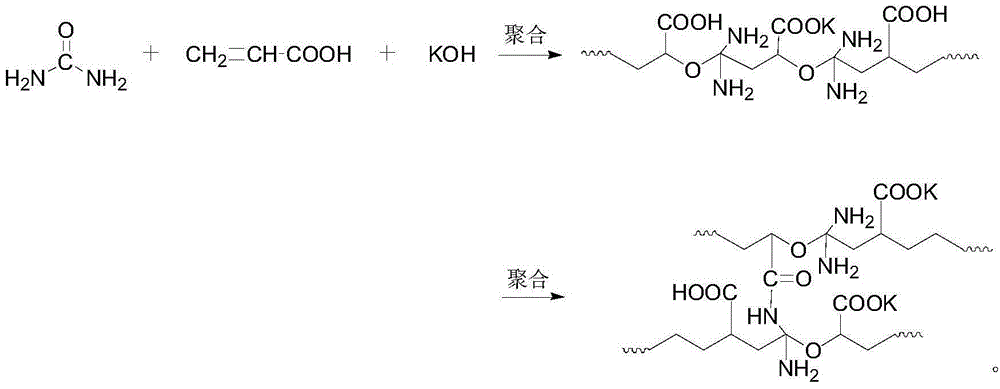

[0029] A preparation method of water-retaining polymer slow-release nitrogen and potassium fertilizer, the steps of which are:

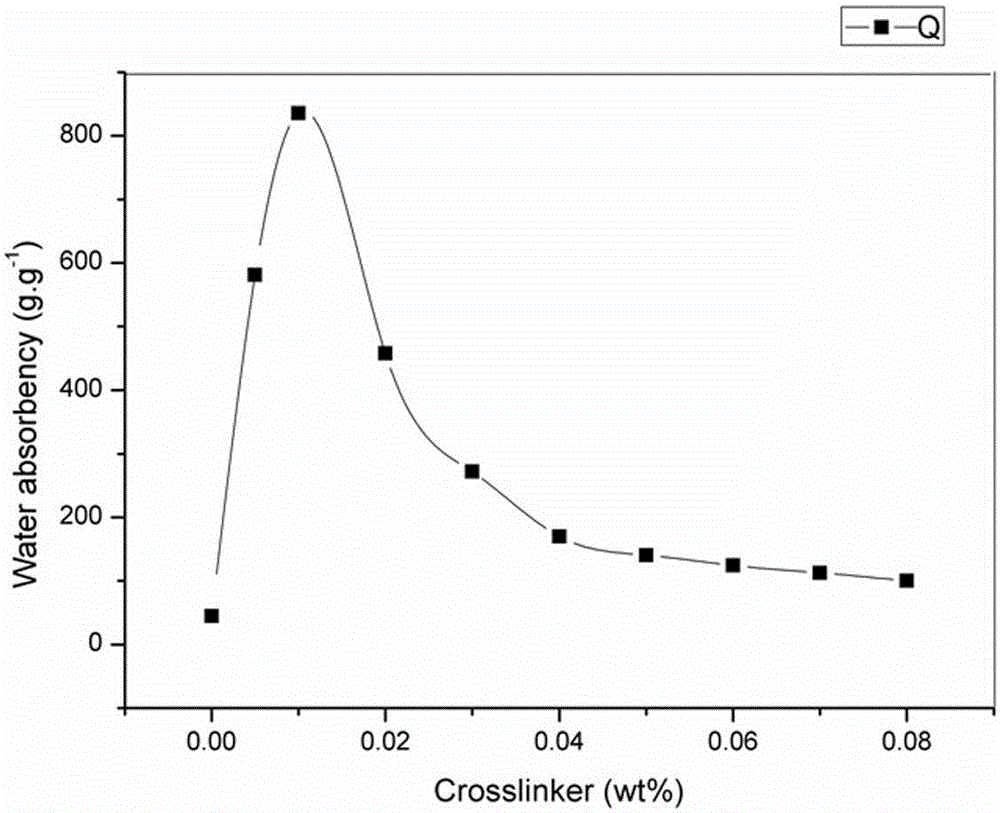

[0030] (1) Add potassium hydroxide solution and acrylic acid (the mass fraction of potassium hydroxide is 20%, and the molar ratio of potassium hydroxide and acrylic acid is 1:1) in the reaction vessel, and stir in an ice bath for 15 minutes until they are evenly mixed; then add The molar ratio of urea to acrylic acid is 1.8:1, stir for 20 minutes until the urea is completely dissolved; then add 0.5% of the mass of acrylic acid initiator potassium persulfate, and stir for 30 minutes until the potassium persulfate is completely dissolved; then add 0.02% of the mass of acrylic acid % cross-linking agent N,N'-methylenebisacrylamide, stir for 20 minutes until the cross-linking agent is completely dissolved, and continue stirring for 30 minutes until the solution is evenly mixed;

[0031] (2) The uniformly mixed solution is sealed, reacted at 75° C. for 2...

Embodiment 2

[0033] A preparation method of water-retaining polymer slow-release nitrogen and potassium fertilizer, the steps of which are:

[0034] (1) Add potassium hydroxide solution and acrylic acid (the mass fraction of potassium hydroxide is 20%, and the molar ratio of potassium hydroxide and acrylic acid is 0.85:1) in the reaction vessel, and stir in an ice bath for 30 minutes until they are evenly mixed; then add The molar ratio of urea to acrylic acid is 0.8:1, stir for 15 minutes until the urea is completely dissolved; then add 2.5% initiator potassium persulfate of the mass of acrylic acid, stir for 15 minutes until the potassium persulfate is completely dissolved; add 0.01% of the mass of acrylic acid % cross-linking agent N,N'-methylenebisacrylamide, stir for 20 minutes until the cross-linking agent is completely dissolved, and continue stirring for 30 minutes until the solution is evenly mixed;

[0035] (2) The uniformly mixed solution is sealed, reacted at 45°C for 4 hours, ...

Embodiment 3

[0037] A preparation method of water-retaining polymer slow-release nitrogen and potassium fertilizer, the steps of which are:

[0038] (1) Add potassium hydroxide solution and acrylic acid (the mass fraction of potassium hydroxide is 20%, and the molar ratio of potassium hydroxide and acrylic acid is 0.95:1) in the reaction vessel, stir in the ice bath for 20min until the mixture is uniform; then add The molar ratio of urea to acrylic acid is 1:1, stir for 20 minutes until the urea is completely dissolved; then add 2.5% initiator potassium persulfate of the mass of acrylic acid, stir for 20 minutes until the potassium persulfate is completely dissolved; add 0.01% of the mass of acrylic acid % cross-linking agent N,N'-methylenebisacrylamide, stir for 15 minutes until the cross-linking agent is completely dissolved, continue stirring for 30 minutes, until the solution is evenly mixed;

[0039] (2) The uniformly mixed solution is sealed, reacted at 45° C. for 4 hours, granulated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com