A kind of cog quality ceramic material for low temperature sintering thin dielectric multilayer ceramic capacitor

A multi-layer ceramic, low-temperature sintering technology, applied in ceramics, inorganic insulators, etc., can solve the problems of sintering furnace pollution, temperature stability of ceramic materials, withstand voltage characteristics, and adverse effects of internal electrode matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

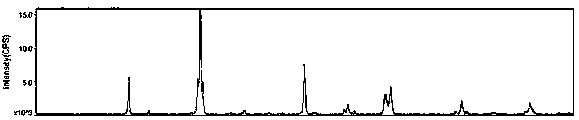

[0017] Refer to Table 1 to and Figures 1 to 4 The present invention is described further, a kind of low-temperature sintering thin-dielectric multilayer ceramic capacitor uses COG quality ceramic material, and its composition comprises main component (Ca 1-x Sr x ) z Zr y o 3 , where 0.2≤x≤0.4, 0.90≤y≤1.0; 0.9850≤z≤1.0030 and additive composition Al 2 o 3 , MnCO 3 , MgO, TiO 2 , SiO 2 、BaCO 3 , Two or more compounds in ZnO.

[0018] The molar content ratio of the components is: (Ca 1-x Sr x ) z Zr y o 3 1mol, Al 2 o 3 0-0.01mol, MnCO 3 0.02-0.1mol, MgO 0-0.01mol, SiO 2 0.02-0.1mol, TiO 2 0-0.005mol, BaCO 3 0-0.01mol for ZnO and 0-0.01mol for ZnO.

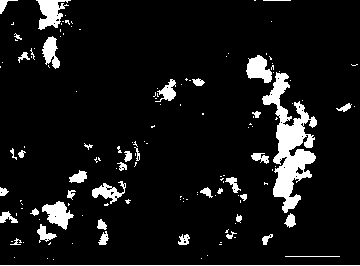

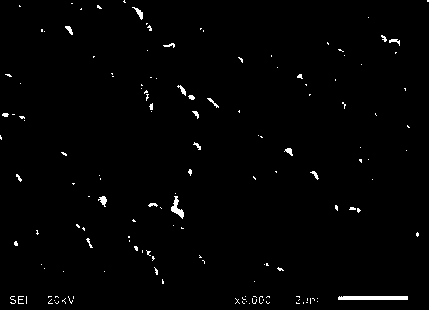

[0019] The (Ca 1-x Sr x ) z Zr y o 3 The manufacturing method adopts hydrothermal synthesis.

[0020] The (Ca 1-x Sr x ) z Zr y o 3 The average particle diameter of the main component material is 50-250 nm.

[0021] The (Ca 1-x Sr x ) z Zr y o 3 It is obtained by calcining at a temperature of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com