Multi-layer coextrusion cast film

A multi-layer co-extrusion and casting film technology, which is applied in the direction of lamination, layered products, lamination devices, etc., can solve the problems of high bonding degree of sealing film and packaging box, damage of sealing film, generation of water vapor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

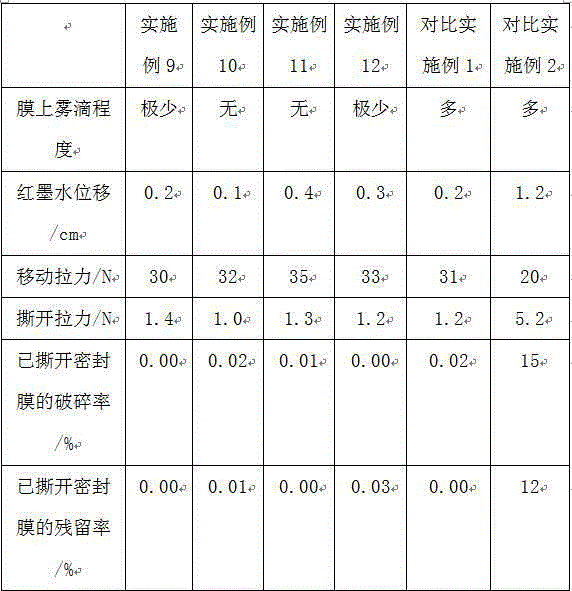

Examples

Embodiment 1

[0040] (1) In parts by weight, take 30 parts of hydrogenated C5 petroleum resin and add it into a reactor whose temperature is controlled at 120° C. After the material is melted, add 15 parts of paraffin, and control the rotating speed at 150 rad / min to start stirring until the sample is completely melted;

[0041] (2) Raise the temperature to 160°C, continue to stir for 0.5h, and then evenly add EVA resin to the reactor several times within 1.5h;

[0042] (3) Add calcium carbonate, control the rotation speed to 200rad / min, stir at a constant speed until uniform, and glue comes out.

Embodiment 2

[0044] (1) In parts by weight, take 35 parts of hydrogenated C5 petroleum resin and add it into a reactor whose temperature is controlled at 120° C. After the material is melted, add 7 parts of paraffin, and control the rotating speed at 100 rad / min to start stirring until the sample is completely melted;

[0045] (2) Raise the temperature to 160°C, continue stirring for 1 hour, and then evenly add EVA resin to the reactor several times within 1.5 hours;

[0046] (3) Add calcium carbonate, control the speed to 100rad / min, stir at a constant speed until uniform, and glue comes out.

Embodiment 3

[0048] (1) In parts by weight, take 40 parts of hydrogenated C5 petroleum resin and add it into a reactor whose temperature is controlled at 120° C. After the material is melted, add 10 parts of paraffin, and control the speed of rotation at 125 rad / min to start stirring until the sample is completely melted;

[0049] (2) Raise the temperature to 160°C, continue stirring for 1 hour, and then evenly add EVA resin to the reactor several times within 1.5 hours;

[0050] (iii) Add calcium carbonate, control the rotating speed to 125rad / min, stir at a constant speed until uniform, and glue comes out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com