Fe2O3/Ag3VO4 composite photocatalyst and preparation method thereof

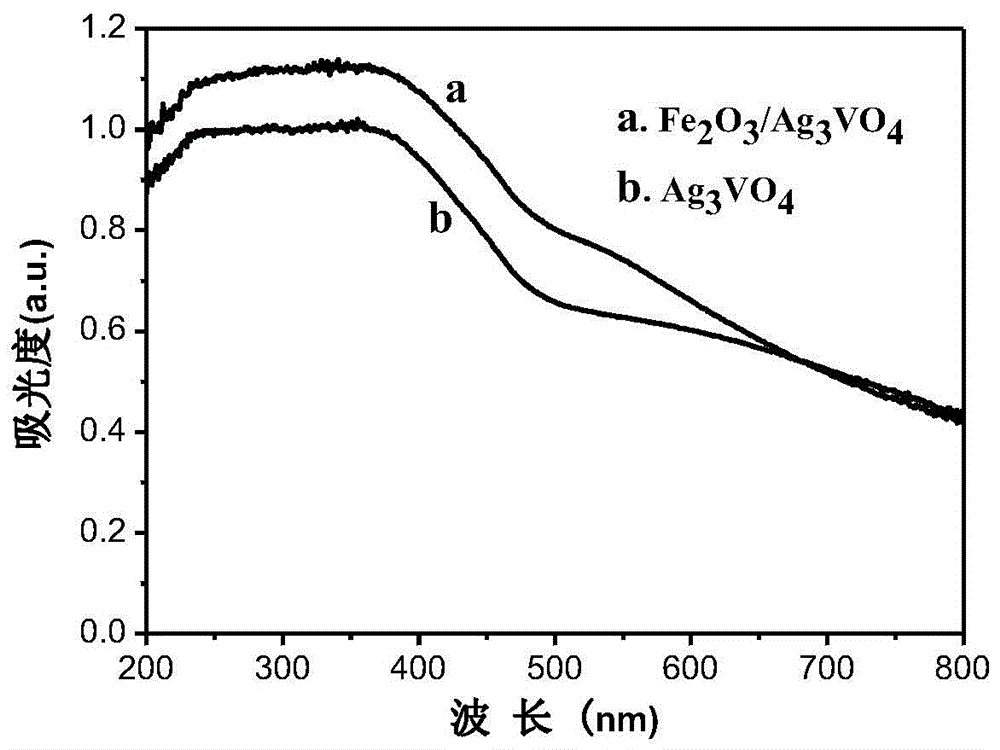

A composite light and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of poor stability, low degradation efficiency of organic dyes, and visible light utilization. It is not a problem such as low cost, the method is simple and easy to implement, and the absorption characteristics are improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

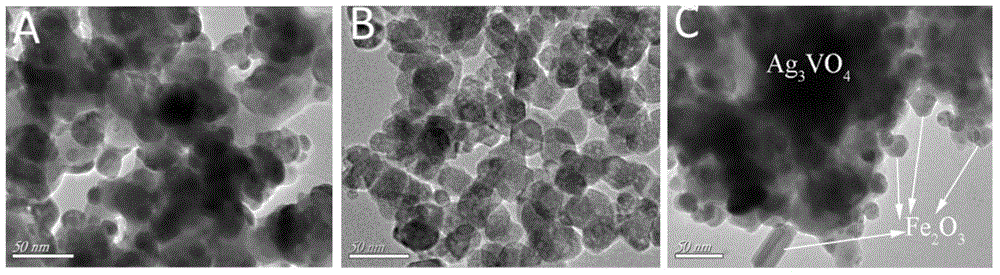

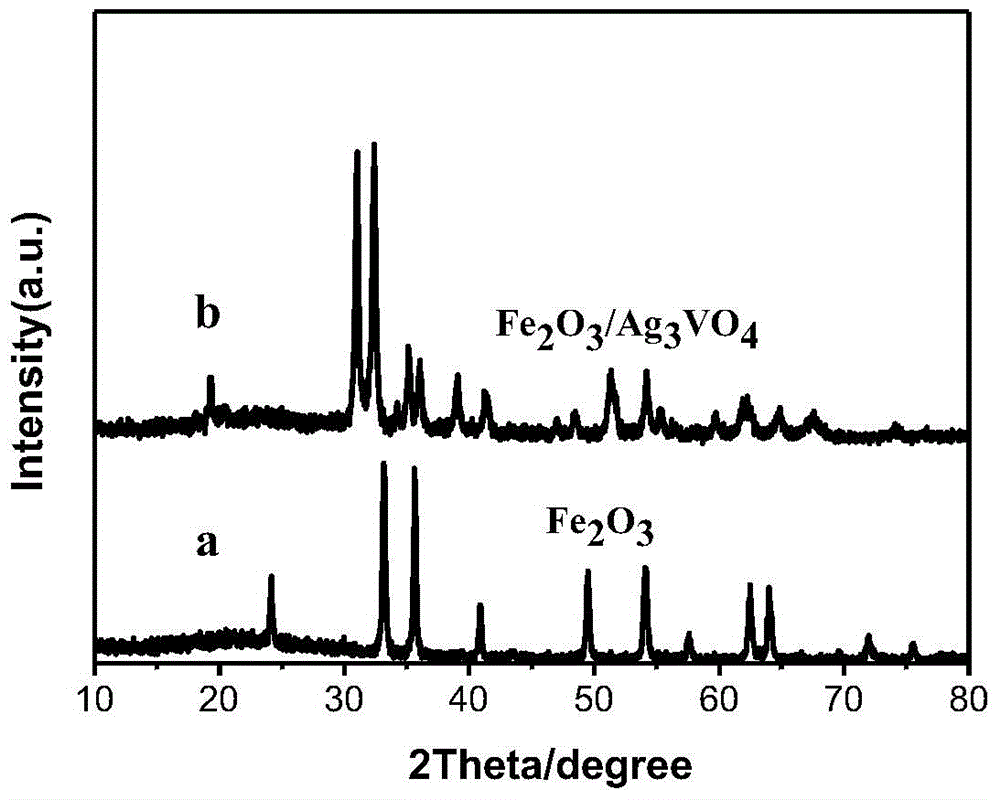

[0028] The iron oxide used was prepared by the following method: Synthesis of nano-particle Fe by hydrothermal method and calcination method 2 o 3 , weighed 8.08gFe(NO 3 ) 3 9H 2 O was placed in a beaker, 80 mL of ethylene glycol (EG) was added and stirred until the nitrate was completely dissolved. Then weigh 7.20gCH 3 COONa and 2g PEG-600 were added to the above solution, and magnetically stirred for 1.5h until a uniform suspension was formed. Then these suspensions were divided into 25mL high-temperature stainless steel reaction kettles, and placed in an oven and heated to 200°C for 22 hours. After the reaction kettle was cooled, the obtained solids were taken out, washed 10 times with water, and washed 10 times with ethanol. Dry in a 60°C oven. Then grind the obtained solid and put it into a crucible, put it in a muffle furnace and heat it up to 500°C for calcination for 2 hours to obtain Fe. 2 o 3 sample. The iron oxides used in Examples 2-5 were all prepared by ...

Embodiment 2

[0037] Put 0.0010g of iron oxide in 40mL of distilled water for ultrasonic dispersion for 10min, and stir in an ice-water bath (0°C) to obtain dispersion A of iron oxide; disperse 0.24g of silver nitrate in the above dispersion to obtain dissolved silver nitrate Iron oxide mixed solution B; at the same time, in an ice water (0°C) bath, dissolve 0.1884g sodium vanadate dodecahydrate in 40mL distilled water to obtain solution C; The prepared C solution was added dropwise to the B solution, and continued to stir in an ice-water bath (0°C) for 120 min; the obtained product was washed and dried to obtain the composite photocatalyst. The material can degrade 90.0% of rhodamine B in 60 minutes under visible light irradiation.

Embodiment 3

[0039] Put 0.0018g of iron oxide in 40mL of distilled water for ultrasonic dispersion for 40min, and stir in 40mL of 30°C constant temperature distilled water to obtain the dispersion A of iron oxide; disperse 0.24g of silver nitrate in the above dispersion to obtain the oxidation Iron mixed solution B; at the same time, under the condition of 30℃ constant temperature water bath, dissolve 0.1900g of sodium vanadate dodecahydrate in 40mL of 30℃ constant temperature water bath to obtain solution C; under the condition of uniform stirring in 30℃ constant temperature water bath, the prepared Add solution C to solution B dropwise, and continue to stir in a constant temperature water bath at 30°C for 120 minutes; wash and dry the obtained product to obtain the composite photocatalyst, which can degrade 88.0% of rhodamine B in 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com