Pulverized coal flow online measuring device and measuring method

A measuring device and technology of pulverized coal, applied in the direction of mass flow measuring device, indirect mass flowmeter, etc., can solve the problems of large measurement error, inability to realize online measurement, and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

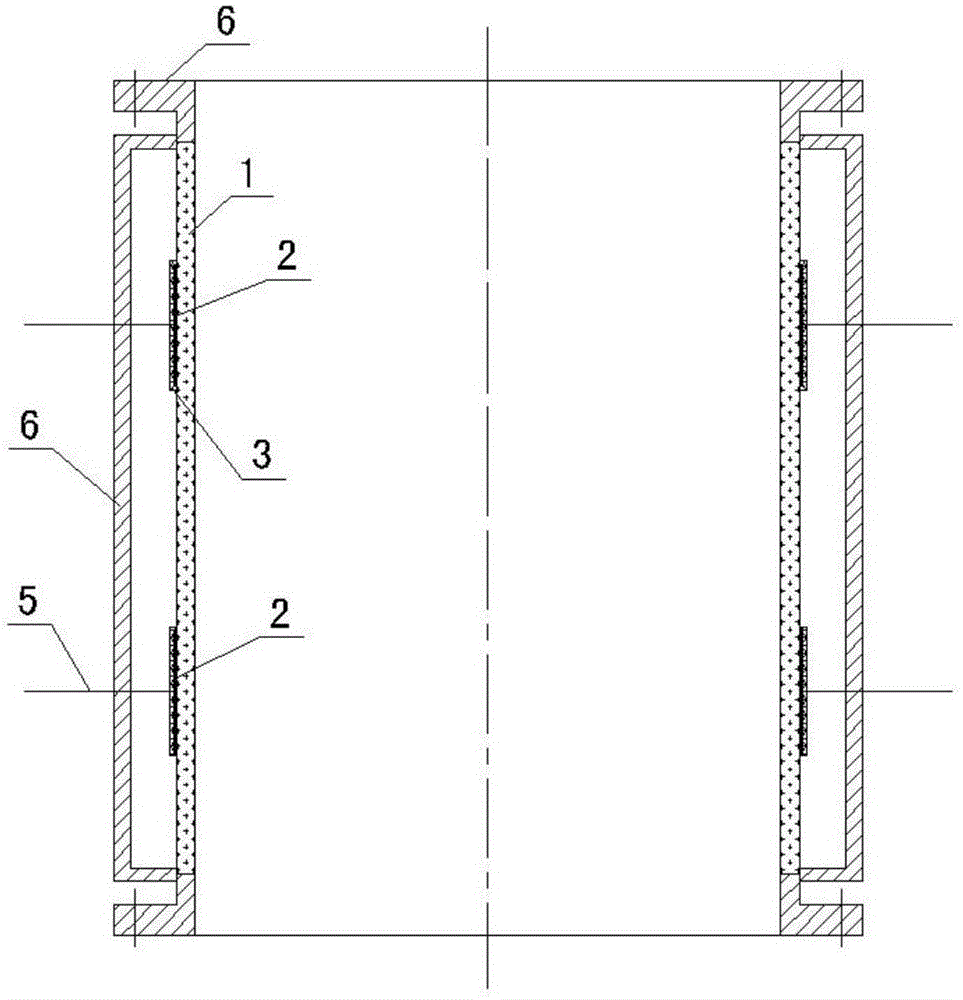

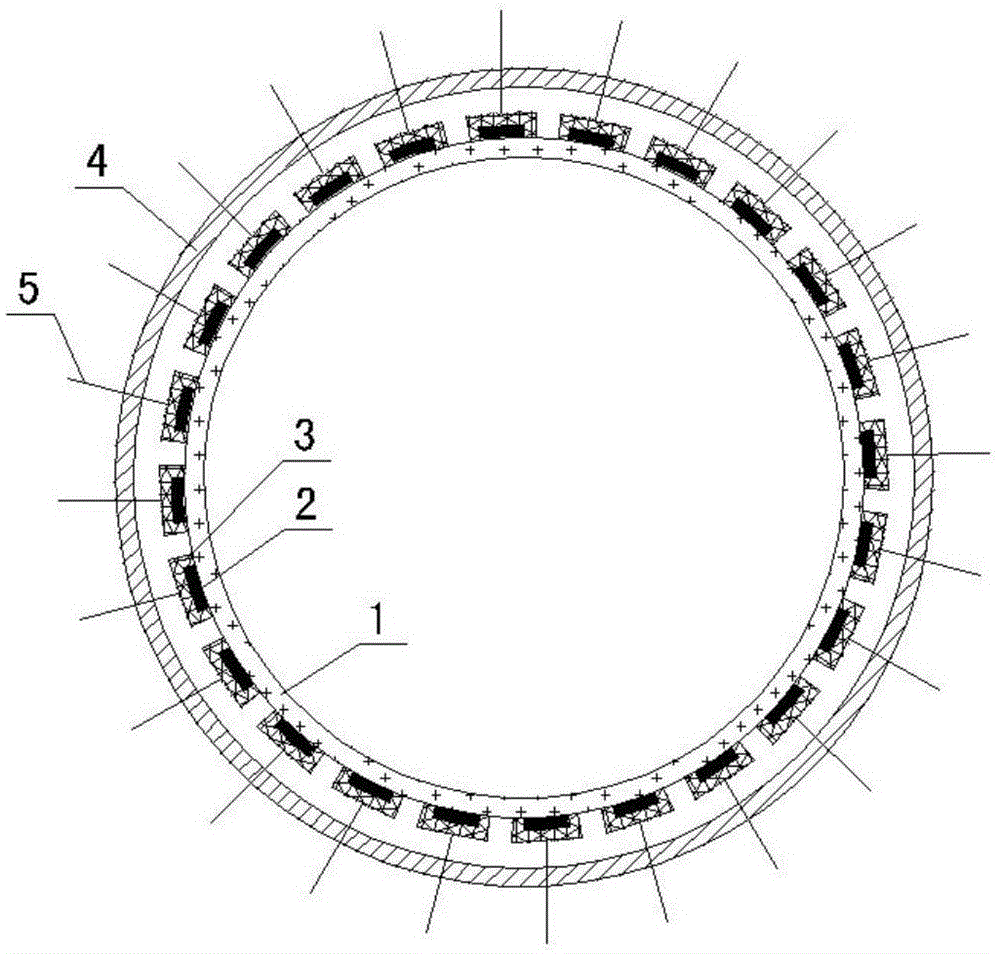

[0038] see figure 1 and figure 2 , the structure of the pulverized coal flow online measuring device in the present embodiment is:

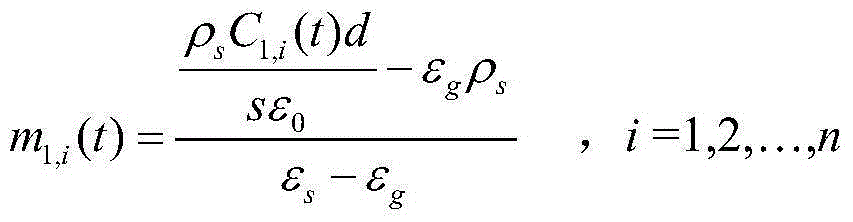

[0039] A section of measuring tube 1 is set in series on the primary air duct. The measuring tube 1 is made of ceramic material, which can prevent the erosion and wear of coal powder. 2n electrode plates 2 are evenly distributed in a circular shape on the outer wall of the measuring tube 1, and the 2n electrode plates 2 form n rectangular plate capacitors facing each other in pairs; the capacitance of the plate capacitors is used as the output signal of the measuring device.

[0040] like figure 1 and figure 2 As shown, in the present embodiment, each shielding case 3 is independently arranged on the outer wall of the measuring tube 1, and the shielding case 3 is a metal mesh covering layer, and each electrode plate 2 is independently enclosed in the shielding case 3 at its respective position; two groups of capacitors The axial distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com