High-moisture coal segmental dehydration drying system and its application method

A drying system and high-humidity technology, applied in the direction of drying machine combination, drying solid materials, heating to dry solid materials, etc., can solve the problems of high energy consumption and changing the physical characteristics of filter cakes, so as to save energy consumption and increase the temperature of raw coal , Improve the effect of energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

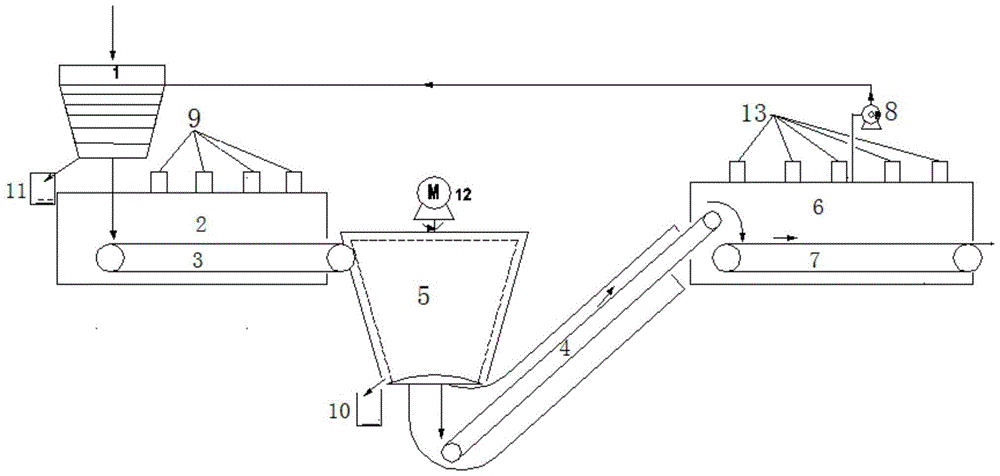

[0042] figure 1 It is a structural diagram of the segmental dehydration drying system in the present invention, the system includes a blanking mechanism for blanking (raw coal, particle size between 30-100mm) and preheating, and the blanking mechanism is a vertically arranged raw coal bunker 1. A heat exchange pipe is arranged along the inner wall of the raw coal bunker 1, and a condensate collection tank 11 is arranged at the bottom of the raw coal bunker 1, and the inlet end of the heat exchange pipe is connected to the outlet end of the dehumidification pump 8. A first microwave drying mechanism 2 is horizontally provided below the raw coal bunker 1, and a horizontally arranged first transmission mechanism 3 for transferring raw coal to the entrance of the solid-liquid separation mechanism 5 is arranged inside the first microwave drying mechanism 2 for solid-liquid separation. The mechanism 5 is arranged vertically or obliquely, the end of the first conveying mechanism 3 is...

Embodiment 2

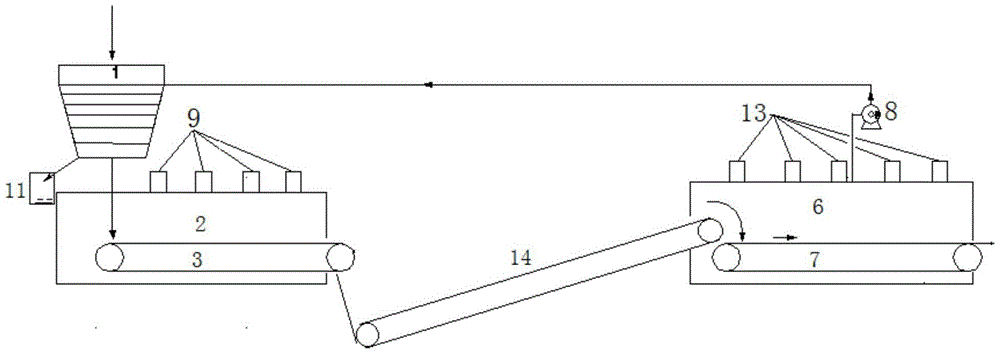

[0066] The segmental dehydration drying system includes a blanking mechanism 1, a first microwave drying mechanism 2, a first transmission mechanism 3, a solid-liquid separation mechanism, a second microwave drying mechanism 6 and a third transmission mechanism 7, wherein the first microwave drying mechanism 2, The structures of the first conveying mechanism 3, the third conveying mechanism 7 and the second microwave drying mechanism 2 are the same as those in Embodiment 1, and the solid-liquid separation mechanism is the fourth conveying mechanism 14 arranged obliquely, and the fourth conveying mechanism 14 includes two Two rollers, a mesh conveyor belt is set between the two rollers, and a vibrating motor fixed to the conveyor belt is arranged under the upper conveyor belt. When the coal material falls from the first conveying mechanism 3 to the fourth conveying mechanism 14, the fourth conveying mechanism The conveying mechanism 14 transports the coal material to the third c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com