Cartridge vane pump and its integrated block

A vane pump, cartridge technology, applied in the direction of rotary piston pumps, pumps, rotary piston/oscillating piston pump components, etc. Integrated installation and other issues, to achieve the effect of promoting promotion and application, light weight, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

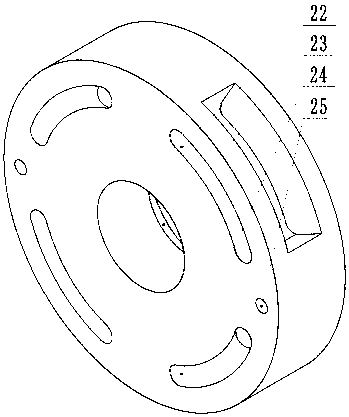

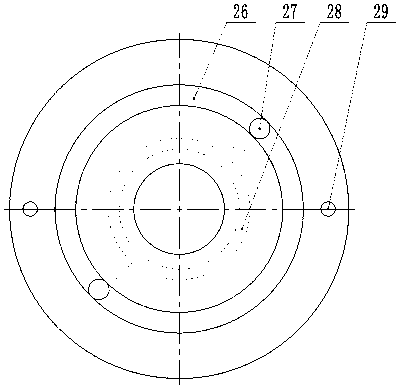

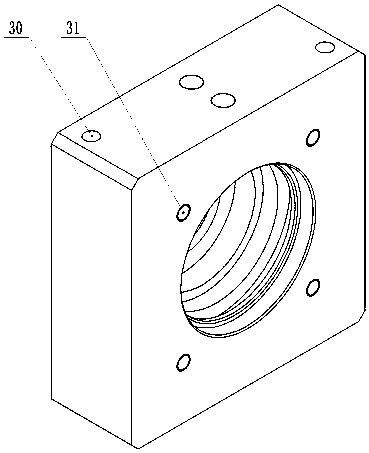

[0018] Such as figure 1 The plug-in vane pump shown is mainly composed of end cover 1, bearing 2, mounting screw 3, pin 4, balance cover plate 5, sealing ring 6, fastening screw 7, blade 8, stator 9, sealing gasket 10, O-ring 11, distribution plate 12, rotor 13, oil inlet and outlet pump housing 14, spring collar 15, oil seal 16 and pump shaft 17; it is characterized in that bearing 2, distribution plate 12, rotor 13, stator 9, balance The cover plate 5 and another bearing are worn on the pump shaft 17 in turn, and after being fixed with the pin 4, the oil seal 16 is installed in the bottom of the pump casing 14 at the inlet and outlet ports, and the spring collar 15 is installed in the collar groove of the pump casing 14 at the inlet and outlet ports. Inside, install the pump shaft 17 in the pump casing 14 of the inlet and outlet ports, install the sealing ring 6 in the sealing ring groove of the end cover 1, cover the end cover 1, and fix it with the fastening screw 7, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com