Novel rotor engine

A rotor engine and rotor technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problem that the applicability of the technical solution does not exceed the comprehensive performance of the piston engine, and the transmission system and gas distribution system of the piston engine are complex and difficult to obtain Reliability and durability and other issues, to achieve the effect of low noise, complementary power, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. Mechanical structure

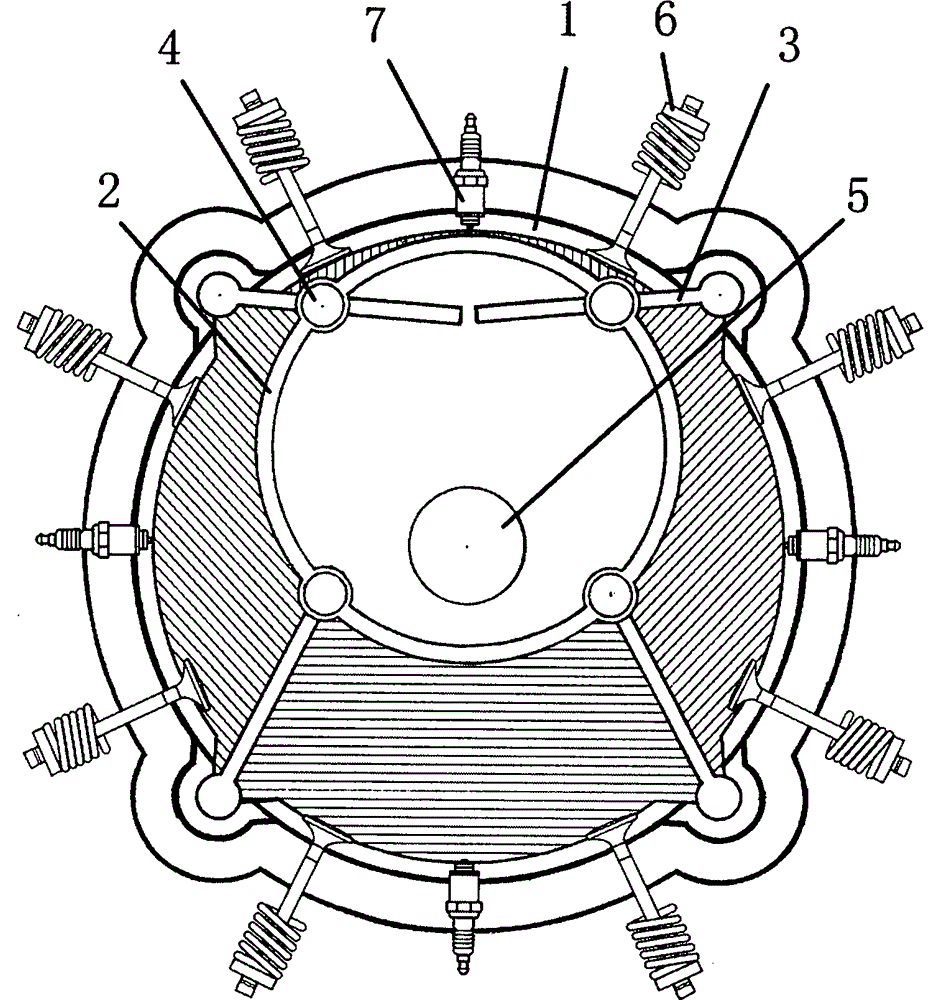

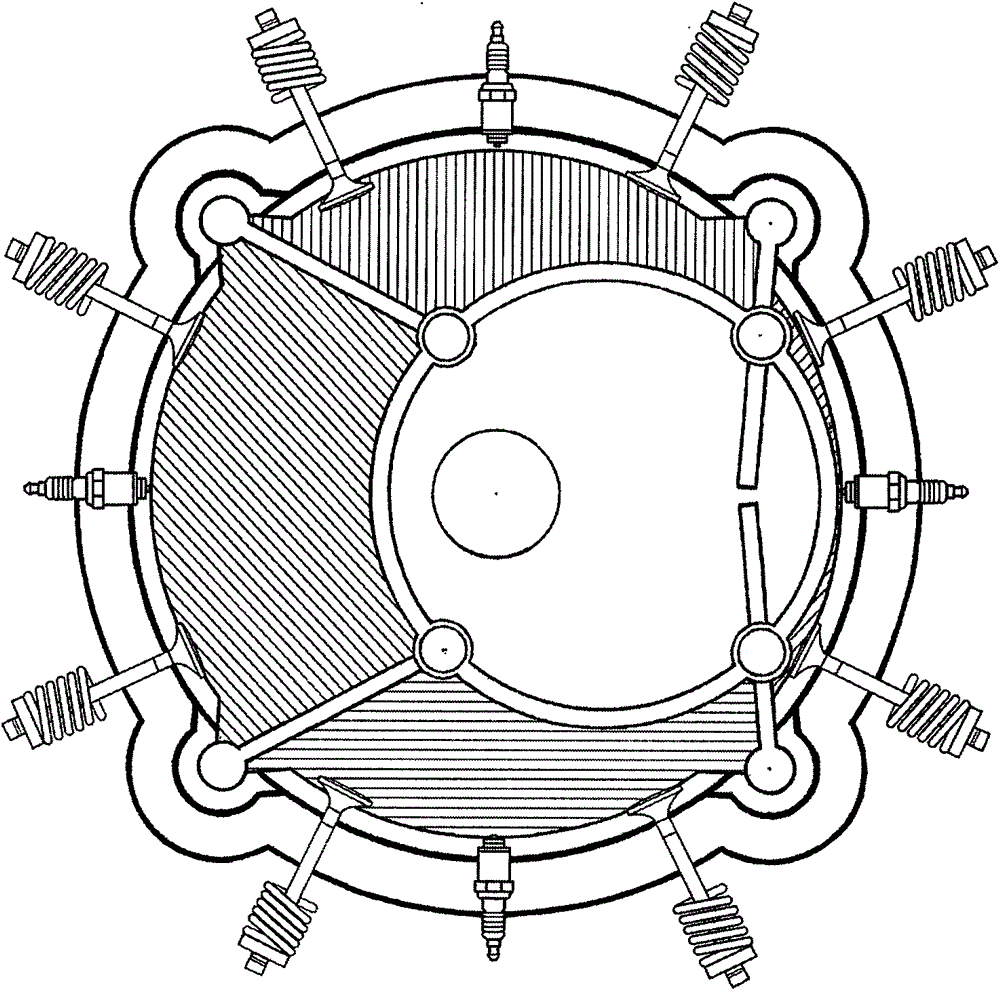

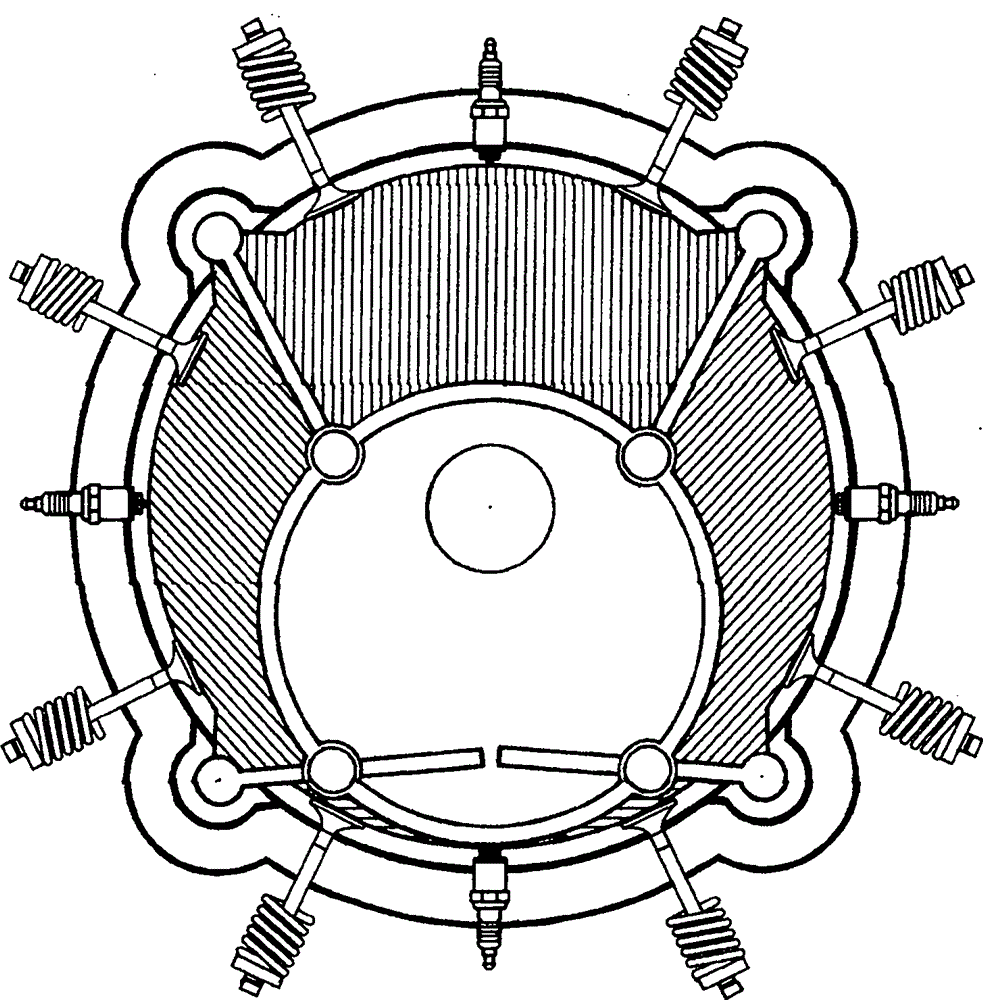

[0019] figure 1 —— Figure 8 It shows 4 combustion chambers in a cylinder, each combustion chamber has a complete four-stroke space change process and the movement of the rotor, as well as the distribution of spark plugs and intake and exhaust mechanisms; Figure 9 Shows the structural shape of the rotor collar (ring type, hollow hole in the middle); Figure 10 The structure and shape of the output shaft turntable are shown; Figure 11 It shows the state of the rotor collar embedded in the output shaft turntable; Figure 12 Another way to show the combination of the isolation plate, the rotor and the cylinder as claimed in claim 8; Figure 13 A perspective view showing the distribution and combination of the main mechanisms of the engine; Figure 14 A three-dimensional view showing the combination of the rotor, the isolation plate, and the airtight bearing; Figure 15 Another way of combining the isolation plate and the rotor described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com