Titanium-aluminum alloy preparation method and preparation device

A technology for preparing equipment and titanium-aluminum alloys, which is applied in the field of preparation equipment and titanium-aluminum alloys, can solve the problems of severe reaction of the thermite reduction method, prolong the holding time, etc., reduce the probability of invasion, increase the density, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

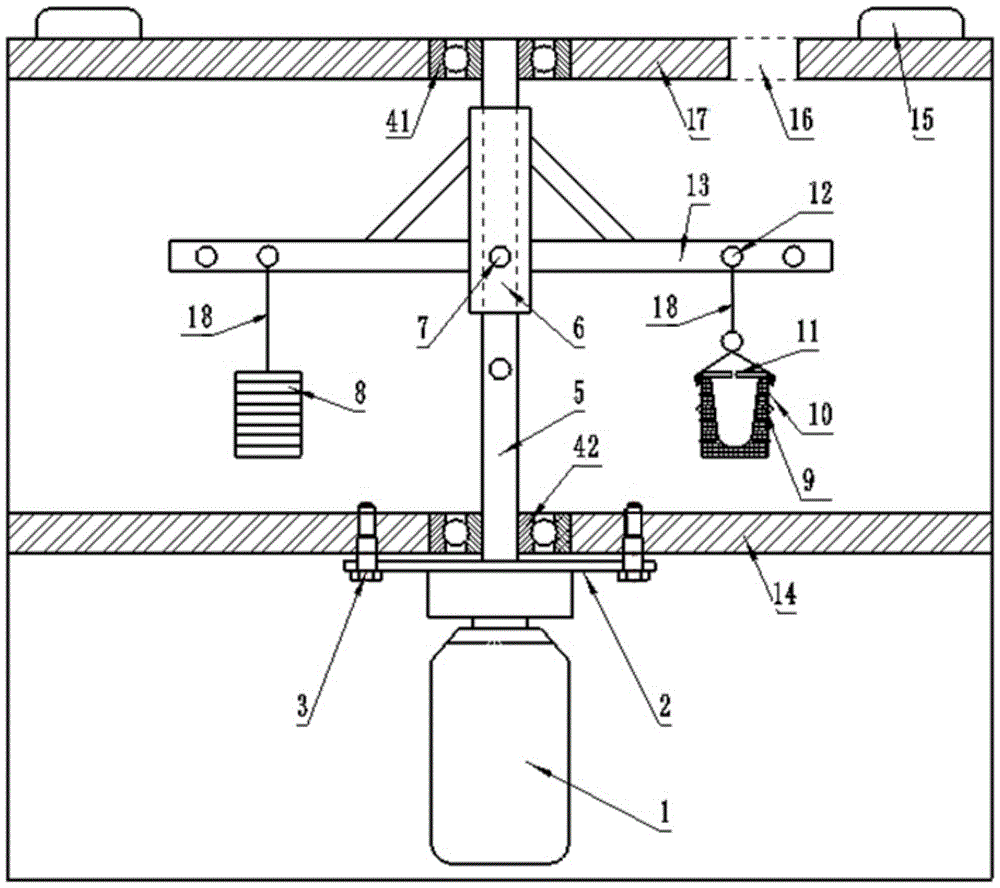

[0030] Take high-titanium slag and aluminum powder in a certain proportion, add absolute ethanol to grind and mix on a ball mill to obtain raw materials, then weigh 2 kg of raw materials, add lime and heating agent potassium chlorate, mix with raw materials evenly, and then put them into the reaction in the can. Add a layer of igniting agent on the surface of the mixture, start the stepless motor 1 after the ignition triggers the reaction, the stepless motor 1 drives the center shaft 5 to rotate, adjust the speed to 1500 rpm, turn off the motor after 30 minutes, and the reaction tank 9 follows the center shaft Slowly decelerate until the rotation stops, and return to the vertical state from the inclined state. After the reactant was cooled to room temperature, it was taken out, and the product was clearly divided into upper and lower layers with a clear interface, the upper layer was slag, and the lower layer was titanium-aluminum alloy. The product with the upper and lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com