Low-VOC (volatile organic compounds) anti-scratch transparent matte varnish and preparation method thereof

A matte varnish, anti-scratch technology, applied in the field of coatings, can solve the general weather resistance problems of aldehyde and ketone resins, and achieve the effect of improving scratch resistance, ensuring hardness and toughness, and excellent high-hardness paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The low-VOC anti-scratch transparent matte varnish of this embodiment is formed by combining the resin paint of component A and the curing agent of component B in a weight ratio of 2:1;

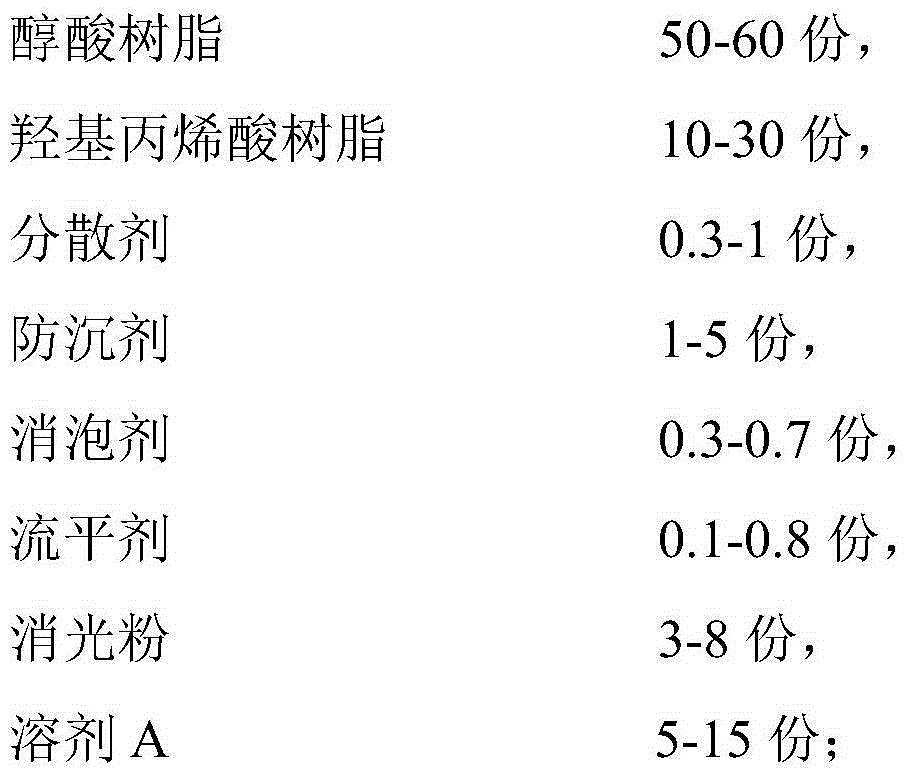

[0047] Wherein, the component A resin paint comprises the following components and parts by weight:

[0048]

[0049] Described component B curing agent comprises following components and weight part content:

[0050] N339070 copies,

[0051] 30 parts of solvent B.

[0052] Solvent A is formed by mixing 5 parts of isobutyl acetate, 5 parts of propylene glycol methyl ether acetate and 3 parts of DBE (divalent ester).

[0053] Solvent B is prepared by mixing 20 parts of isobutyl acetate and 10 parts of DBE (dibasic acid ester).

[0054] The preparation method of the low VOC anti-scratch transparent matte varnish of the present embodiment specifically comprises the following steps:

[0055] (1) Add solvent A to the dispersing kettle in parts by weight, add alkyd resin and hydroxyacry...

Embodiment 2

[0062] The low-VOC anti-scratch transparent matte varnish of this embodiment is formed by combining the resin paint of component A and the curing agent of component B in a weight ratio of 2:1;

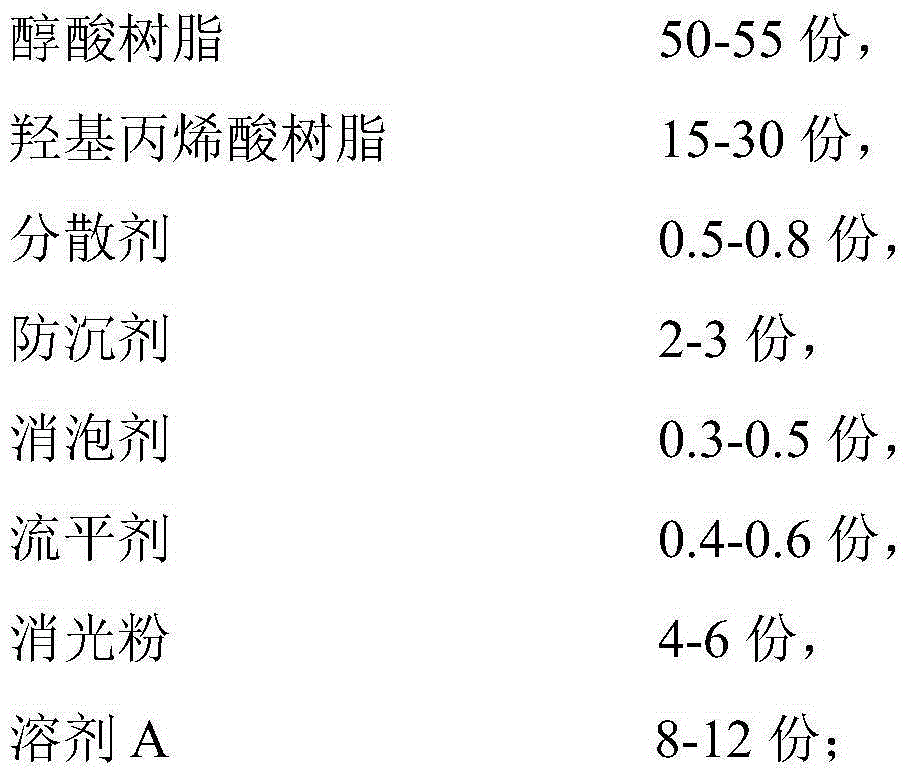

[0063] Wherein, the component A resin paint comprises the following components and parts by weight:

[0064]

[0065]

[0066] Described component B curing agent comprises following components and weight part content:

[0067] N339065 copies,

[0068] 35 parts of solvent B.

[0069] Solvent A and solvent B are mixed solvents composed of isobutyl acetate, propylene glycol methyl ether acetate and divalent ester in a weight ratio of 2:1:1.

[0070] The preparation method of the low VOC anti-scratch transparent matte varnish of the present embodiment specifically comprises the following steps:

[0071] (1) Add solvent A to the dispersing kettle in parts by weight, add alkyd resin and hydroxyacrylic resin and stir evenly, then add matting powder and dispersant, stir at 400 rpm for...

Embodiment 3

[0075] The low-VOC anti-scratch transparent matte varnish of this embodiment is formed by combining the resin paint of component A and the curing agent of component B in a weight ratio of 2:1;

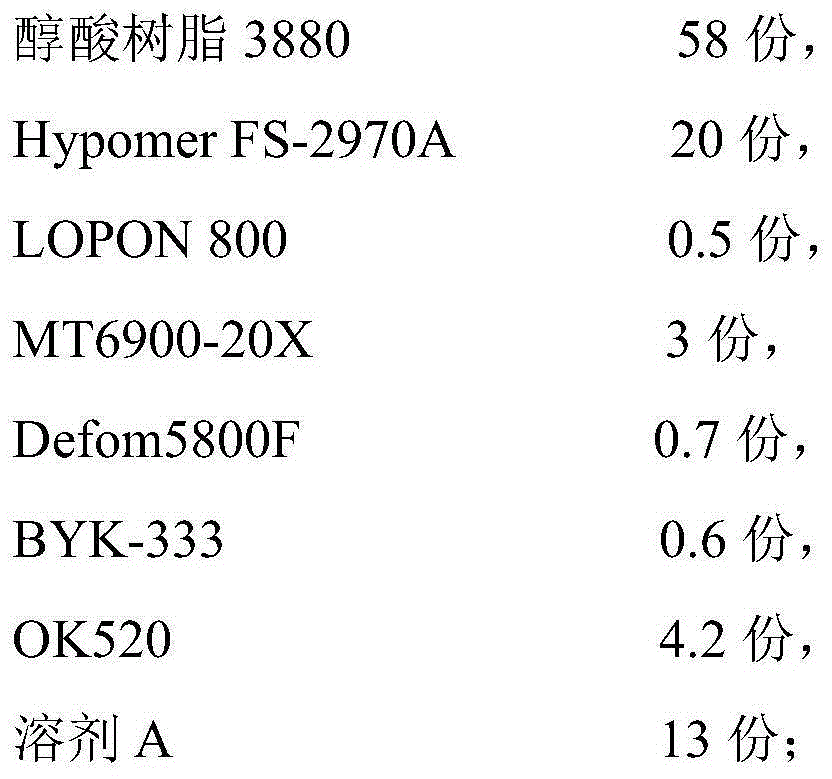

[0076] Wherein, the component A resin paint comprises the following components and parts by weight:

[0077]

[0078] Described component B curing agent comprises following components and weight part content:

[0079] N339055 copies,

[0080] 20 parts of solvent B.

[0081] Solvent A and solvent B are mixed solvents composed of isobutyl acetate, propylene glycol methyl ether acetate and divalent ester in a weight ratio of 2:1:1.

[0082] The preparation method of the low VOC anti-scratch transparent matte varnish of the present embodiment specifically comprises the following steps:

[0083] (1) Add solvent A into the dispersing kettle in parts by weight, add alkyd resin and hydroxyacrylic resin and stir evenly, then add matting powder and dispersant, stir at 500 rpm for 25 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com