Efficient treatment system of oil sludge

A treatment system and technology for sludge, applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of not being able to deal with sludge in time, increasing equipment operation failures, increasing environmental pollution, etc. problems, to achieve the effect of high degreasing and dust removal efficiency, high oil-water separation efficiency, and water conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

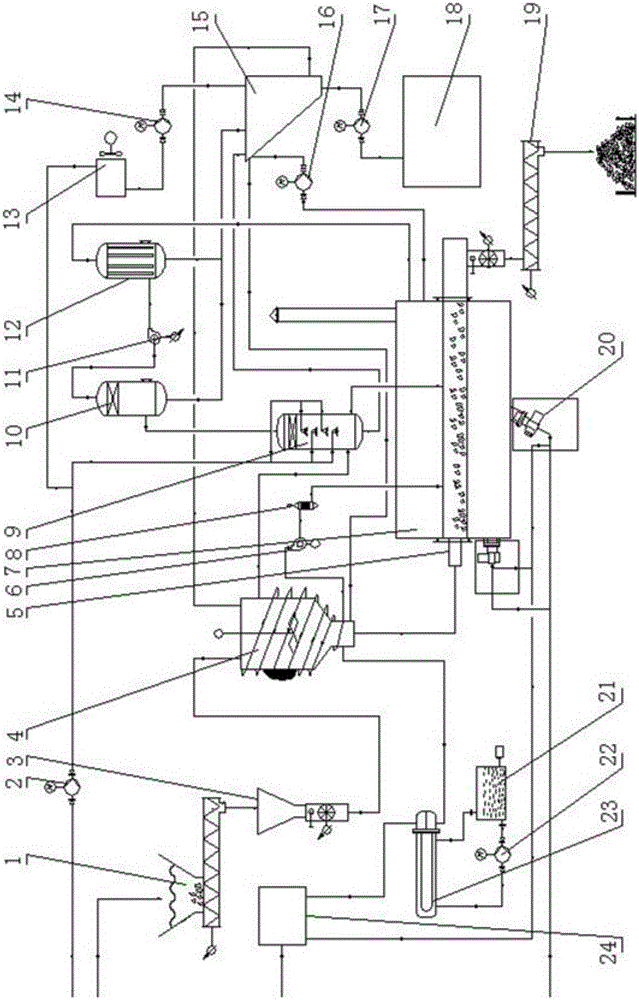

[0019] Such as figure 1 As shown, the high-efficiency sludge treatment system includes a sludge delivery unit, a drying unit, a thermal analysis unit, a combustion unit, a gas treatment unit, a condensate treatment unit, and a sludge output unit; the sludge delivery unit includes a screw conveyor 1 connected in sequence and an air belt Locked material storage bin 3; the drying unit includes a dryer 4 with an agitator and an external heating coil, a flue gas blower 6, an electrical filter 8, an oil tank 21 with an electric heater, an oil pump 22, a heat exchanger 23 and a system Nitrogen machine 24, nitrogen generator 24, heat exchanger 23, drier 4 with agitator and external heating coil, flue gas blower 6, electrical filter 8 are connected in sequence, oil pump 22, oil tank 21 with electric heater It is connected to the heat exchanger 23, and the oil pump 22 is connected to the oil tank 21 with an electric heater, and the dryer 4 with an agitator and an external heating coil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com