Method for preparing SiO2-coated Au@Ag core-shell nanorod

A nanorod and core-shell technology, applied in the direction of coating, etc., can solve the problems of easy mutual aggregation of AuAg core-shell nanorods, cumbersome preparation process, strong biological toxicity, etc., and achieve good dispersion, simple method, and low biological toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of Au nanorods by seed growth method

[0028] Add 200 μL 0.01mol / L chloroauric acid aqueous solution and 48 μL 0.1mol / L sodium borohydride aqueous solution (stored in the refrigerator at 0-4°C) to 8 mL of 0.1mol / LCTAB aqueous solution, the color becomes brownish yellow, stir evenly, and then put Standing and reacting in an oven at 30° C. for 2 hours to obtain gold seed sol.

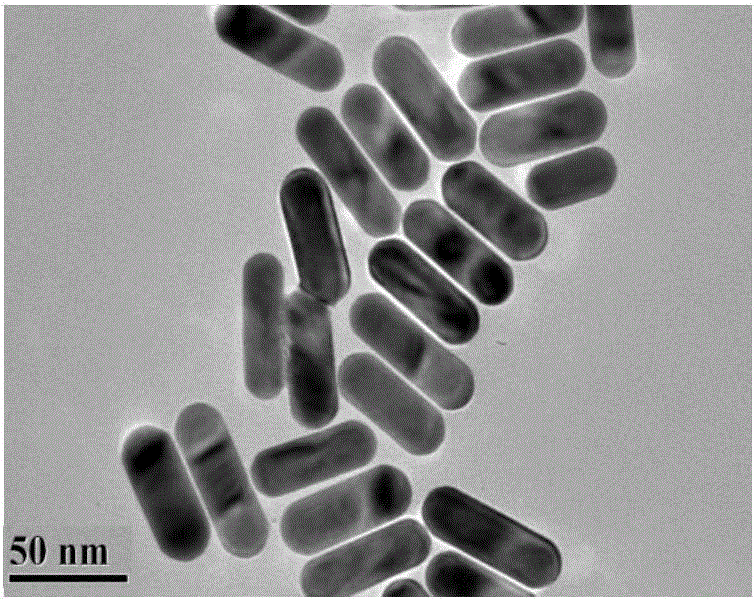

[0029] To 20 mL of 0.1 mol / L cetyltrimethylammonium bromide aqueous solution, add 1 mL of 0.01 mol / L chloroauric acid aqueous solution, 250 μL of 0.01 mol / L silver nitrate aqueous solution, 33.5 μL of 38% hydrochloric acid aqueous solution, 160 μL of 0.1 mol / L ascorbic acid aqueous solution was stirred evenly to obtain a seed growth solution. Add 10 μL of gold seed sol to the obtained seed growth solution, stir evenly, then put it in an oven and let it stand for 12 hours at 30°C to react for 12 hours, centrifuge, wash with deionized water, and obtain Au nanorods (see figure 1 ).

...

Embodiment 2

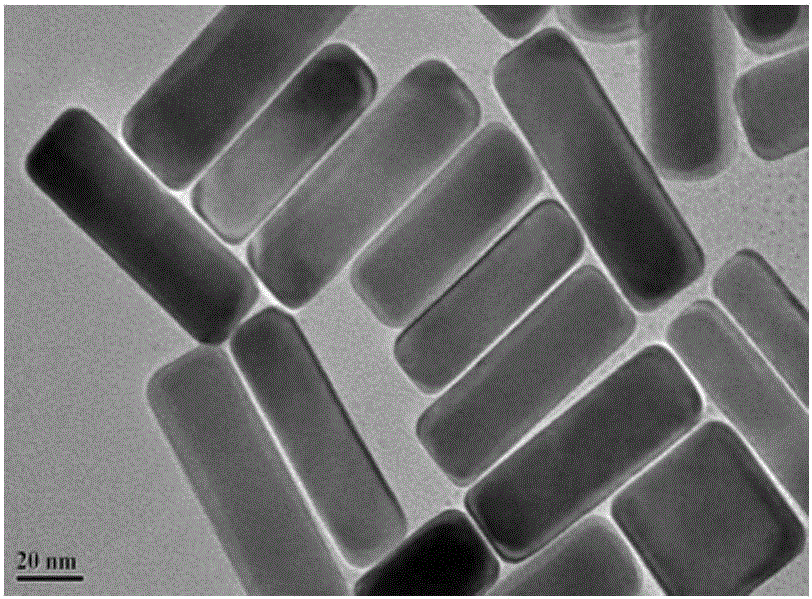

[0035] Step 1 and Step 2 of this embodiment are the same as those of Embodiment 1. In the preparation of AuAgSiO 2In step 3 of core-shell nanorods, add 2mL of AuAg core-shell nanorods into 16mL of deionized water, ultrasonically disperse evenly, add 0.05g of polyvinylpyrrolidone with a number average molecular weight of 10,000, stir at room temperature for 1 hour, add 50mL of isopropanol, and ultrasonically disperse Evenly, add 2.5mL ammonia water, and dropwise add 20μL tetraethyl orthosilicate, react at 40°C for 3.5 hours, wash with deionized water and ethanol, respectively, to obtain SiO 2 AuAgSiO coated with a thickness of about 30nm 2 Core-shell nanorods (see Figure 4 ).

Embodiment 3

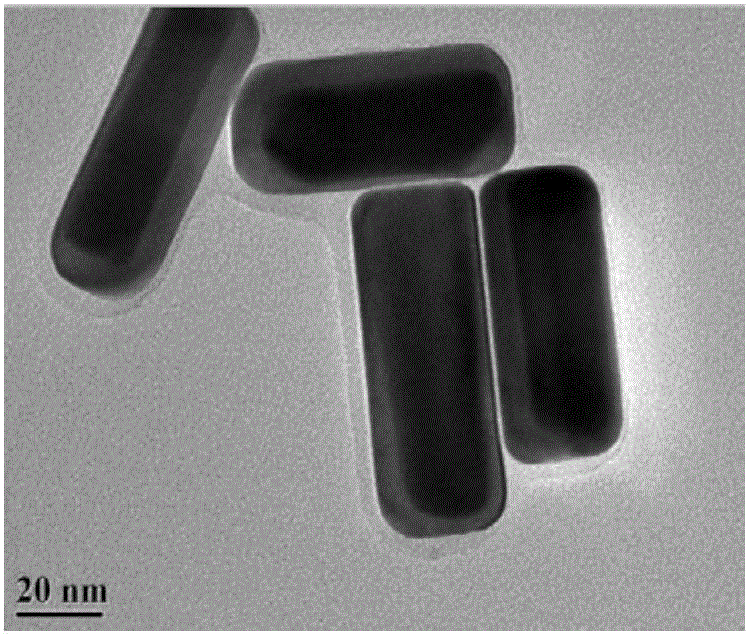

[0037] Step 1 and Step 2 of this embodiment are the same as those of Embodiment 1. In the preparation of AuAgSiO 2 In step 3 of core-shell nanorods, add 2mL of AuAg core-shell nanorods into 16mL of deionized water, ultrasonically disperse evenly, add 0.05g of polyvinylpyrrolidone with a number average molecular weight of 10,000, stir at room temperature for 1 hour, add 50mL of isopropanol, and ultrasonically disperse Evenly, add 4 mL of ammonia water, and dropwise add 40 μL of tetraethyl orthosilicate, react at 40 °C for 3.5 hours, wash with deionized water and ethanol, respectively, to obtain SiO 2 AuAgSiO coated with a thickness of about 70nm 2 Core-shell nanorods (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com