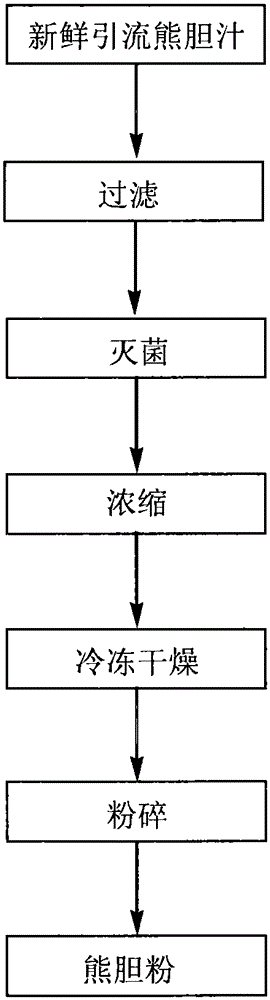

Preparation method for bear bile powder

A technology of bear bile powder and bear bile, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, and unknown raw materials, can solve problems such as inactivation of active enzymes, changes in the structure of active ingredients, and affect the effectiveness of drugs, so as to improve The effect of quality and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1 kg of freshly drained bear bile, vacuum filter it to obtain the filtrate; add ethanol to the filtrate to make the ethanol content in the liquid 75%, stir for 20 minutes, and let it stand for 24 hours; concentrate the liquid under reduced pressure at 35°C to remove ethanol , to obtain sterilized bear bile liquid; the sterilized bear bile liquid is cooled to -35°C at a cooling rate of 4°C / min, kept at a constant temperature for 0.5h, vacuumed to 1Pa, and then heated to room temperature at a heating rate of 3°C / min. Freeze-drying operation; after freeze-drying, pulverize to obtain bear bile powder.

[0024] After testing, the content of tauroursodeoxycholic acid in the obtained bear bile powder was 28.9%, and no Staphylococcus aureus, Bacillus aeruginosa and Salmonella were detected through hygienic inspection.

Embodiment 2

[0026] Take 2kg of freshly drained bear bile, filter it under reduced pressure to obtain the filtrate; add ethanol to the filtrate to make the ethanol content in the liquid medicine 85%, stir for 40 minutes, and let stand for 72 hours; concentrate the liquid medicine under reduced pressure at 45°C to remove Ethanol to obtain sterilized bear bile liquid; the sterilized bear bile liquid is cooled to -40°C at a cooling rate of 2°C / min, kept at a constant temperature for 3.5 hours, vacuumed to 15Pa, and then heated to room temperature at a heating rate of 3°C / min The freeze-drying operation is realized; after the freeze-drying is completed, it is pulverized into golden yellow bear bile powder with transparent luster.

[0027] After testing, the content of tauroursodeoxycholic acid in the obtained bear bile powder was 29.4%, and no Staphylococcus aureus, Bacillus aeruginosa and Salmonella were detected through hygienic inspection.

Embodiment 3

[0029] Take 4kg of freshly drained bear bile, filter it under reduced pressure to obtain the filtrate; add ethanol to the filtrate to make the ethanol content in the liquid medicine 80%, stir for 30 minutes, and let stand for 48 hours; concentrate the liquid medicine under reduced pressure at 40°C to remove Ethanol to obtain sterilized bear bile liquid; the sterilized bear bile liquid is cooled to -38°C at a cooling rate of 1°C / min, kept at a constant temperature for 2 hours, vacuumed to 10Pa, and then heated to room temperature at a heating rate of 2°C / min. Freeze-drying operation; after freeze-drying, it is pulverized into golden-yellow bear bile powder with transparent luster.

[0030] After testing, the content of tauroursodeoxycholic acid in the obtained bear bile powder was 29.2%, and no Staphylococcus aureus, Bacillus aeruginosa and Salmonella were detected through hygienic inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com