Aloe tobacco substitute product and manufacturing method thereof

A production method and substitute technology, which is applied in the field of aloe vera tobacco substitutes and its production, can solve the problems of damage and cancer, and achieve the effects of low addiction, reduction of myocardial infarction, and moderate energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

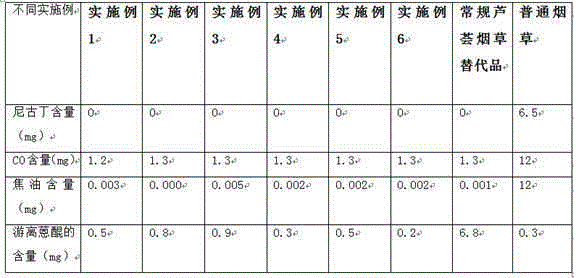

Examples

Embodiment 1

[0052] An aloe tobacco substitute is processed from aloe leaves, and its specific production steps are:

[0053] 1) Preparation of materials:

[0054] The leaves and stems of fresh aloe are used to remove impurities and spoiled parts, washed with clean water that meets the national drinking water standards, and the cortex and fleshy parts are separated, and the cortex is made into 1mm wide aloe silk, and the fleshy part of aloe is passed through Grinding into pulp, removing fiber, ethanol precipitation, centrifugal filtration and freeze-drying to obtain aloe extract, which is stored for later use;

[0055] 2) Pretreatment of material preparation:

[0056] Mix and soak the chopped aloe vera and licorice, soak in an organic solvent with a concentration of 5-25% for 60 minutes at a temperature of 45°C, fish out the soaked aloe vera, wash and drain the aloe vera;

[0057] 3) Baking:

[0058] Bake the washed and drained aloe silk at a temperature of 40°C for 48 hours, and contro...

Embodiment 2

[0064] An aloe tobacco substitute is processed from aloe leaves, and its specific production steps are:

[0065] 1) Preparation of materials:

[0066] The leaves and stems of fresh aloe are used to remove impurities and spoiled parts, washed with water that meets the national drinking water standards, the cortex and fleshy parts are separated, and the cortex is made into 3mm wide aloe silk, and the fleshy part of aloe is passed through Grinding into pulp, removing fiber, ethanol precipitation, centrifugal filtration and freeze-drying to obtain aloe extract, which is stored for later use;

[0067] 2) Pretreatment of material preparation:

[0068] The cut aloe vera and licorice are mixed and soaked, soaked in an organic solvent with a concentration of 25% for 180 minutes, and the soaking temperature is 85°C, and the soaked aloe is taken out, and the aloe is washed and drained;

[0069] 3) Baking:

[0070] Baking the washed and drained aloe silk at a temperature of 90°C for 96...

Embodiment 3

[0076] An aloe tobacco substitute is processed from aloe leaves, and its specific production steps are:

[0077] 1) Preparation of materials:

[0078] The leaves and stems of fresh aloe are used to remove impurities and spoiled parts, washed with water that meets the national drinking water standards, the cortex and fleshy parts are separated, and the cortex is made into 2mm wide aloe silk, and the fleshy part of aloe is treated Grinding into pulp, removing fiber, ethanol precipitation, centrifugal filtration and freeze-drying to obtain aloe extract, which is stored for later use;

[0079] 2) Pretreatment of material preparation:

[0080] Mix and soak the chopped aloe vera and licorice, soak in hot ethanol solution with a concentration of 15% for 150min at a temperature of 70°C, fish out the soaked aloe and licorice, and wash the aloe and licorice drying;

[0081] 3) Baking:

[0082] Baking the washed and drained aloe vera silk at a temperature of 80°C for 72 hours, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com