Piston ring and method for producing same

A piston ring and annular technology, which is applied in the field of piston rings and its manufacturing, can solve the problems of adverse effects of the working environment, not easy to increase the film thickness, etc., achieve excellent long-term preservation, improve the working environment, and suppress the generation of microcracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1 and 2

[0067] The components shown in Table 1 below were added to water to prepare a trivalent chromium plating solution having the composition shown in the table. Using the obtained plating solution, electroplating was performed under the conditions shown in the table to form a plated film on the surface of the base material. As the anode, a high-density graphite plate is used. As the cathode, low-chromium steel, which is one of the base materials of piston rings, is used.

[0068] In addition, as the base material for plating, low-chromium steel (front end 10R with size 5×5×20) is used for wear resistance evaluation of the plating film, etc., and SUS304 (size 50×100×5mm) is used for corrosion resistance sex evaluation. After the plating treatment, the obtained plated product was heat-treated at 200° C. for 30 minutes in the air, and then each evaluation was performed.

Embodiment 4

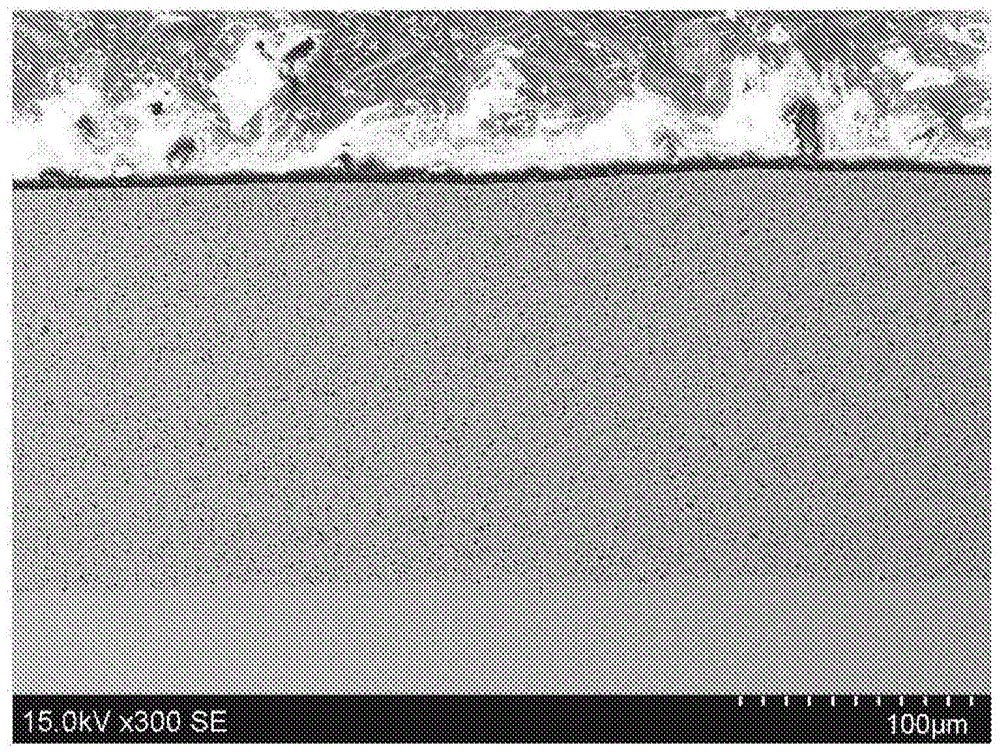

[0109]Prepare a plating solution with trivalent chromium having the same composition as in Example 1 except that scale-like molybdenum disulfide particles with an average thickness of 1 μm and an average diameter of 6 μm at 30 g / liter are added as particles with self-lubricating properties. The same method as Example 1 was used to make a piston ring with coating. The scanning electron micrograph of the longitudinal section of the manufactured piston ring is shown in Figure 4 . Figure 4 The dark parts are molybdenum disulfide particles, and it was confirmed that a good plating film was formed in which scale-like molybdenum disulfide particles were arranged laterally so as to block current. The surface friction of this coating was measured, and the value was 23% of the surface friction of the coating of Example 1. In addition, a piston ring was produced using the same plating solution as in Example 1 except that spherical molybdenum disulfide particles having an average part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com