High-voltage battery containing aqueous electrolyte

A water-based electrolyte and high-voltage technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of high price, battery safety, and high working voltage of lithium-ion batteries, achieving cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Negative electrode: Zn;

[0007] Negative electrode electrolyte: 4mol / LNaOH and 0.5mol / LNa 2 SO 4 mixture;

[0008] Positive electrode: MnO 2 :superPLi:PVDF=90:5:5;

[0009] Positive electrode production method: mix manganese dioxide, conductive agent (superPLi), and binder (PVDF) according to the mass ratio of 90:5:5, and then use a suitable solvent to make slurry, stir evenly and apply it on a specific current collector Just dry;

[0010] Positive electrode electrolyte: 1mol / LH 2 SO 4 and 0.5mol / LNa 2 SO 4 mixture;

[0011] Diaphragm: Nafion—Na + (sodium ion exchange membrane).

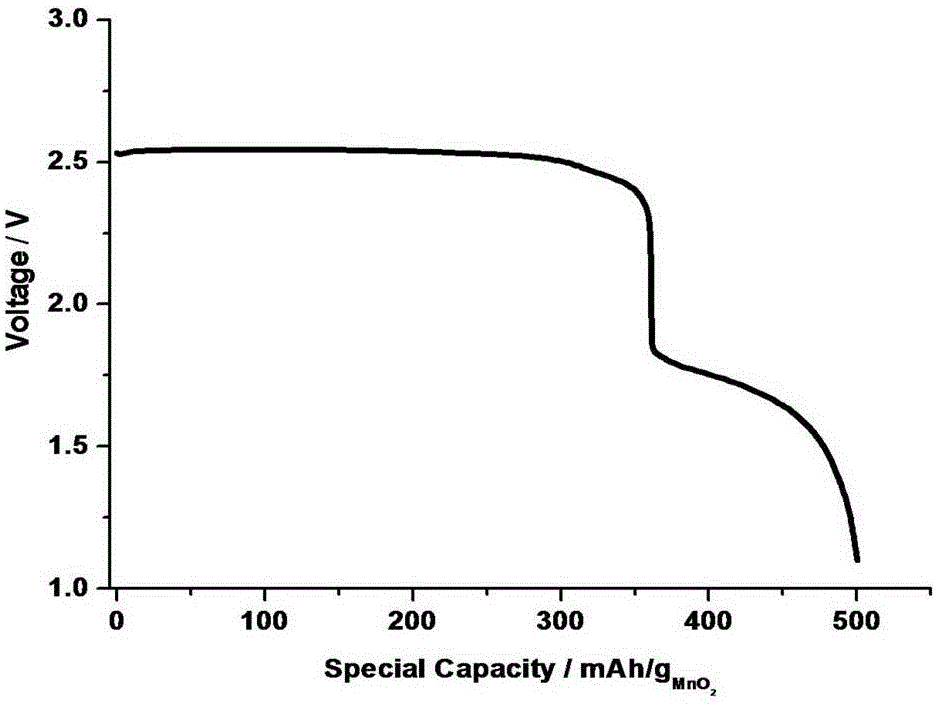

[0012] Battery at 123.2mA / g MnO2 Discharge to 1.1V under the current density, the discharge medium voltage is 2.52V, and the capacity reaches 500mAh / g MnO2 . See the attached discharge curve figure 1 .

Embodiment 2

[0014] Negative electrode: Zn;

[0015] Negative electrode electrolyte: 8mol / L ammonia water and 0.5mol / LNa 2 SO 4 mixture;

[0016] Positive electrode: MnO 2 :superPLi:PVDF=90:5:5;

[0017] Positive electrode production method: mix manganese dioxide, conductive agent (superPLi), and binder (PVDF) according to the mass ratio of 90:5:5, and then use a suitable solvent to make slurry, stir evenly and apply it on a specific current collector Just dry;

[0018] Positive electrode electrolyte: 1mol / LH 2 SO 4 and 0.5mol / LNa 2 SO 4 mixture;

[0019] Diaphragm: Nafion—Na + (sodium ion exchange membrane).

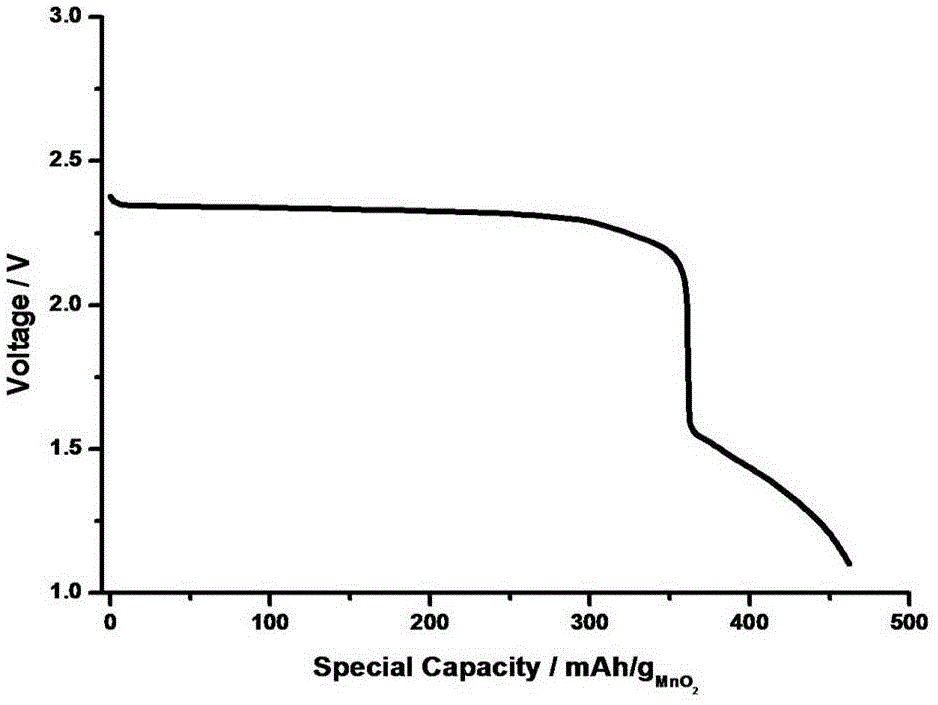

[0020] Battery at 246.4mA / g MnO2 Discharge to 1.1V under current density, discharge medium voltage is 2.32V, capacity reaches 462mAh / g MnO2 . See the attached discharge curve figure 2 .

Embodiment 3

[0022] Negative electrode: Mg;

[0023] Negative electrolyte: V(DMSO):V(EtOH)=1:3 saturated NH 4 Cl solution;

[0024] Positive electrode: MnO 2 :superPLi:PVDF=90:5:5;

[0025] Positive electrode production method: mix manganese dioxide, conductive agent (superPLi), and binder (PVDF) according to the mass ratio of 90:5:5, and then use a suitable solvent to make slurry, stir evenly and apply it on a specific current collector Just dry;

[0026] Positive electrode electrolyte: 1mol / LH 2 SO 4 and 0.5mol / LNa 2 SO 4 mixture

[0027] Diaphragm: Nafion—Na + (sodium ion exchange membrane).

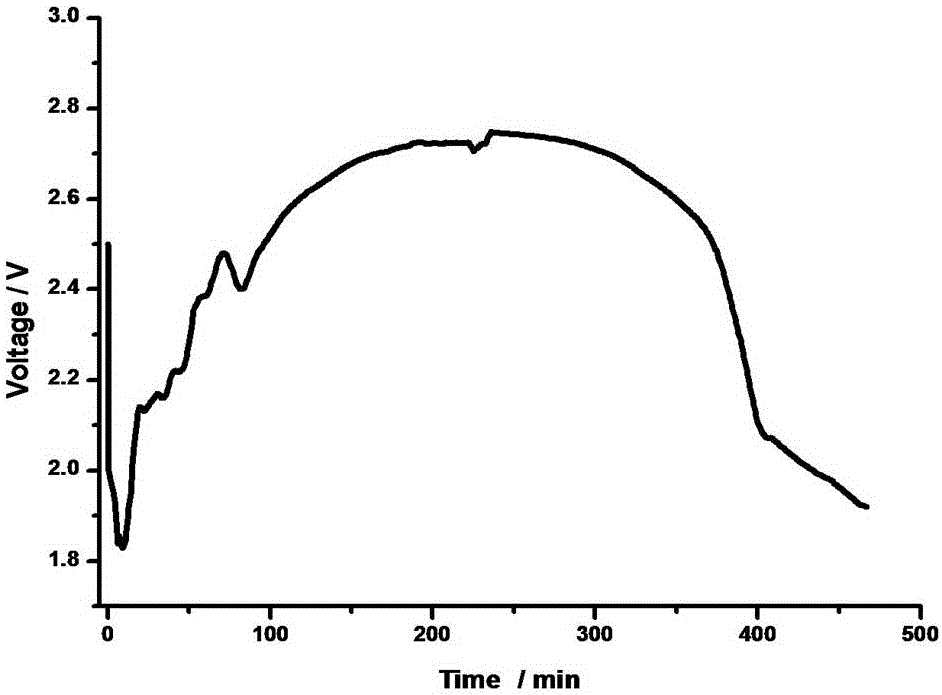

[0028] Battery at 60mA / g MnO2 The discharge curve under the current density is shown in the appendix image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com