Metallurgical lime calcium oxide content determination method

A measurement method, calcium oxide technology, is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, which can solve the problems of long detection cycle, reduced detection cost, and cumbersome steps. Achieve the effects of shortened detection cycle, shortened measurement time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

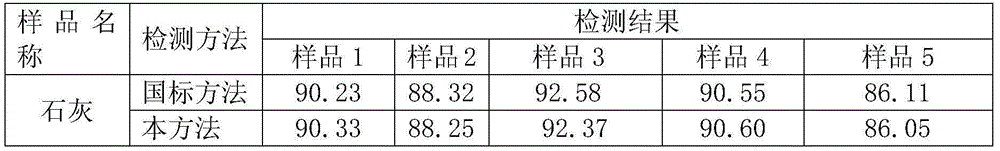

Examples

Embodiment Construction

[0018] The present invention will be described in detail below by way of examples.

[0019] The assay method of calcium oxide content in described metallurgical lime, concrete steps are as follows:

[0020] (1) Weigh 0.25g sample and place it in a 100ml beaker, add 25ml of hydrochloric acid with a volume fraction of 20% for heating and dissolving, then transfer it into a 250ml volumetric flask, constant volume, and mix for subsequent use;

[0021] (2) Take 25ml from the 250ml sample solution obtained in step (1) and place it in a 300ml conical flask, add 5ml of triethanolamine with a volume fraction of 33.33%, 10ml of sodium hydroxide with a concentration of 200g / L and 0.1g Calcium indicator, titrate with EDTA standard solution from red to blue as the end point, record the volume V;

[0022] (3) According to the formula: Calculate the result, where m is the sample weight g, c is the EDTA concentration, and r is the fractionation ratio.

[0023] The calcium indicator in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com