Nondestructive test method for microhardness of metal surface layer subjected to laser shock processing

A laser shock strengthening and microhardness technology, applied in the direction of testing the hardness of materials, can solve the problems of surface integrity and surface topography, and achieve the effect of improving the surface topography and damage to the surface integrity, and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, but the present invention should not be limited to the examples.

[0016] The base material of the metal part used in this embodiment is 316L stainless steel, and its geometric size is 120mm×60mm×15mm. A square area of 30mm×30mm is selected in the middle of the surface for laser shock strengthening treatment.

[0017] An example of the surface hardness of a metal part after laser shock strengthening of an example measured using the above method, the steps are:

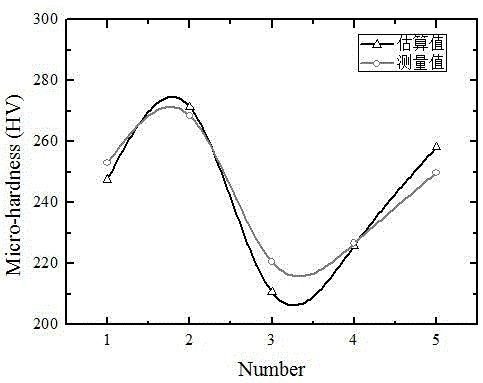

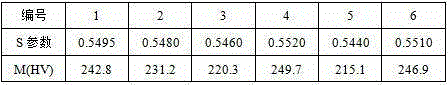

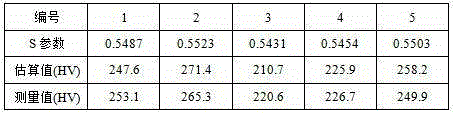

[0018] (1) Select 316L stainless steel metal parts after laser shock strengthening, first select 6 points on the surface of the impact area, and measure the S parameter value of Doppler broadening spectrum at each point after laser shock strengthening, which is regarded as S1, S2······S6, its values are shown in Table 1, and the process parameters in the process o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com