Dynamic pressure sensor chip

A sensor chip and dynamic pressure technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, fluid pressure measurement using optical methods, etc., can solve the problem of large acceleration effect, low working temperature, and aggravated p-n junction leakage, etc. problems, to achieve the effect of ensuring dynamic characteristics, excellent performance and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

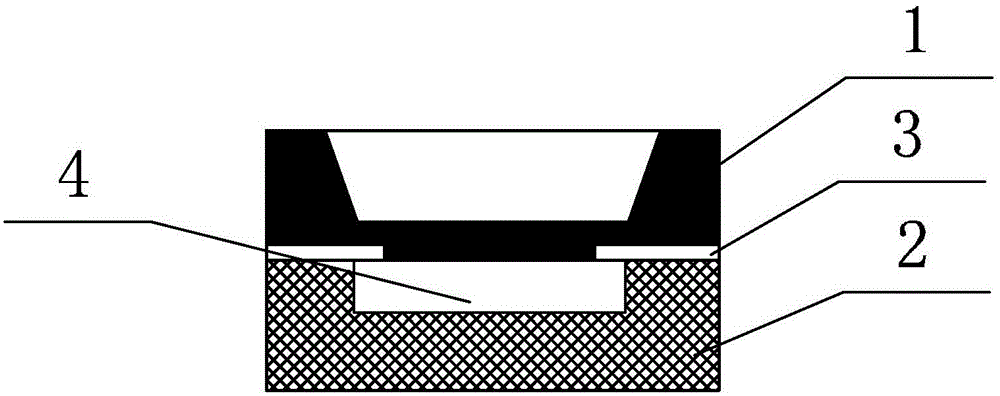

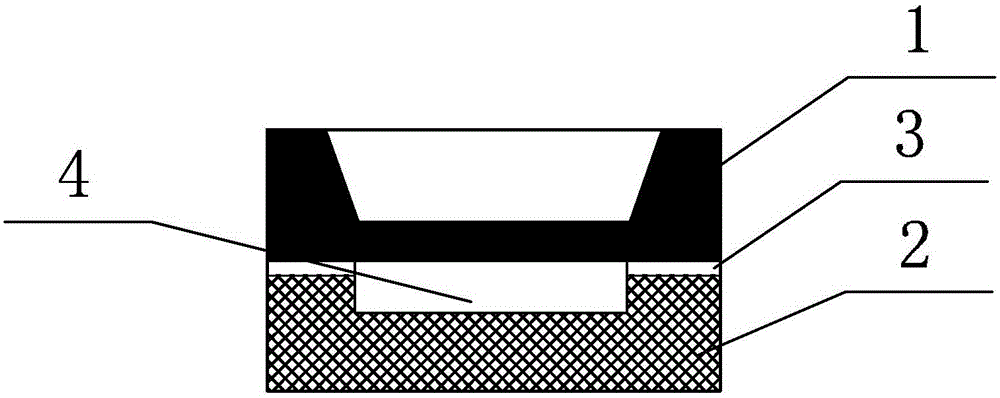

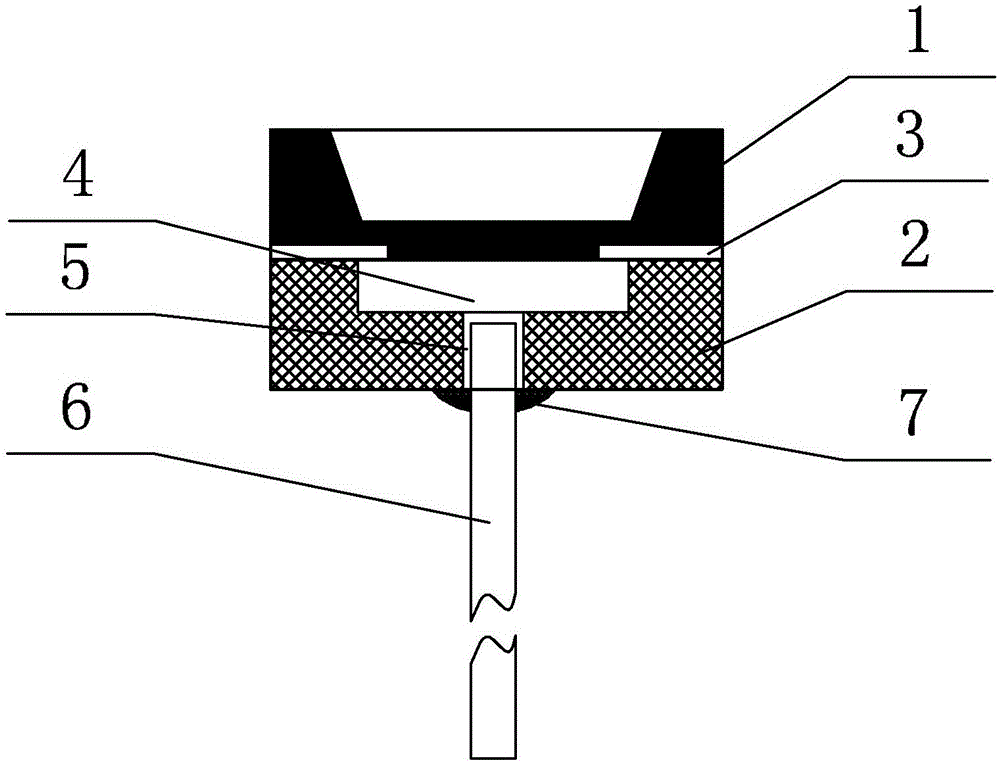

[0016] Specific implementation mode 1. Combination Figure 1 to Figure 8 Illustrate following specific implementation mode, it comprises pressure-sensitive chip 1 and glass substrate 2, and the bonding surface of pressure-sensitive chip 1 is electrostatically sealed and bonded on the bonding surface of glass substrate 2; In pressure-sensitive chip 1 and glass substrate 2, the four sides of the bonding surface of the pressure sensitive chip 1 or the four sides of the bonding surface of the glass substrate 2 are evenly and symmetrically provided with microfluidic channels 3.

specific Embodiment approach 2

[0017] Embodiment 2. The difference between this embodiment and the dynamic pressure sensing chip described in Embodiment 1 is that the material of the pressure sensitive chip 1 is a silicon wafer or a high temperature resistant SOI wafer made by oxygen injection isolation technology.

specific Embodiment approach 3

[0018] Embodiment 3. The difference between this embodiment and the dynamic pressure sensing chip described in Embodiment 1 or 2 is that the pressure sensitive chip 1 adopts a flat membrane or beam membrane piezoresistive structure or a flat membrane with an optical mirror surface. Or corrugated membrane structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com