Wind-water atomizing aspirating device for mines

An atomization dust reduction and geomancy technology, applied in safety devices, parts of pumping devices for elastic fluids, dust prevention, etc., can solve problems such as destroying mines, loss of life and property, and heavy casualties, and improve atomization efficiency , to overcome the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

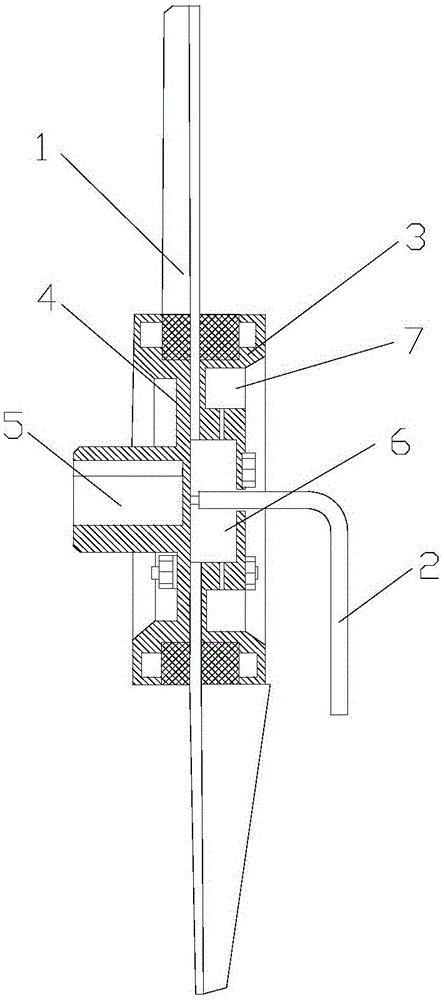

[0025] This embodiment provides a wind water atomization and dust suppression device for mining, the structure is as follows figure 1 As shown, it includes an atomizer, a blade 1 and a water receiving pipe 2. The atomizer includes a front hub 3 and a rear hub 4 fixedly connected by bolts. The water inlet cavity 6 and the atomization cavity 7 communicated through the water guide tube. The atomization cavity is a ring-shaped structure set outside the water inlet cavity. Bolts are fixed between the front hub and the rear hub, and the blades are integrally injection-molded with high-strength polyethylene plastic; the front hub is made of titanium alloy, which has strong corrosion resistance; the composition and mass percentage of titanium alloy are: C: 0.32%, Al : 4.2%, Mg: 1.1%, Cr: 1.7%, Mn: 0.55%, Si: 0.05%, Ni: 2.2%, Ru: 0.11%, Nb: 0.09%, V: 0.14%, B: 0.15%, Zr : 0.7%, W: 0.056%, Cu: 0.17%, Mo: 0.33%, La: 0.02%, Ce: 0.01%, Pm: 0.05%, Tb: 0.03%, Dy: 0.015%, and the balance is ...

Embodiment 2

[0037]This embodiment provides a wind and water atomization and dust suppression device for mining. The structure is the same as that of Embodiment 1, the difference lies in the composition of the titanium alloy. The composition and mass percentage of the titanium alloy are: C: 0.36%, Al: 4.9%, Mg: 1.3%, Cr: 1.8%, Mn: 0.59%, Si: 0.06%, Ni: 2.5%, Ru: 0.17%, Nb: 0.10%, V: 0.15%, B: 0.20%, Zr: 0.8%, W: 0.057%, Cu: 0.18%, Mo: 0.34%, La: 0.03%, Ce: 0.02%, Pm: 0.06%, Tb: 0.05%, Dy: 0.019%, and the balance is Ti;

[0038] Among them, the impurity content is controlled at N≤0.002%, H≤0.004%, P: 0.008%, S: 0.003%.

[0039] The heat treatment method of the titanium alloy parts in the mine-used Fengshui atomization and dust suppression device comprises the following steps:

[0040] 1) Clean titanium alloy parts with acetone;

[0041] 2) Place the cleaned titanium alloy parts on the base of the fixture for positioning, position the clamping block assembly and pressing assembly on the ti...

Embodiment 3

[0049] This embodiment provides a wind and water atomization and dust suppression device for mining. The structure is the same as that of Embodiment 1, the difference lies in the composition of the titanium alloy. The composition and mass percentage of the titanium alloy are: C: 0.39%, Al: 5.7%, Mg: 1.5%, Cr: 1.9%, Mn: 0.63%, Si: 0.07%, Ni: 2.8%, Ru: 0.21%, Nb: 0.11%, V: 0.16%, B: 0.25%, Zr: 0.9%, W: 0.058%, Cu: 0.19%, Mo: 0.35%, La: 0.04%, Ce: 0.02%, Pm: 0.07%, Tb: 0.06%, Dy: 0.025%, and the balance is Ti;

[0050] Among them, the impurity content is controlled at N≤0.002%, H≤0.004%, P: 0.009%, S: 0.004%.

[0051] The heat treatment method of the titanium alloy parts in the mine-used Fengshui atomization and dust suppression device comprises the following steps:

[0052] 1) Clean titanium alloy parts with acetone;

[0053] 2) Place the cleaned titanium alloy parts on the base of the fixture for positioning, position the clamping block assembly and pressing assembly on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com