Modacrylic carbon-doped fiber gray fabric after-treatment process and device

A technology of acrylic fiber mixed with carbon and fiber fabric, which is applied in the field of textiles, and can solve the problems of poor textile processing characteristics of acrylic fiber mixed with carbon fiber, affecting the reliability of product protection, and reducing the adsorption performance of fabrics, so as to improve the appearance quality and reduce Effects of damage to fabric strength and recovery of absorbency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

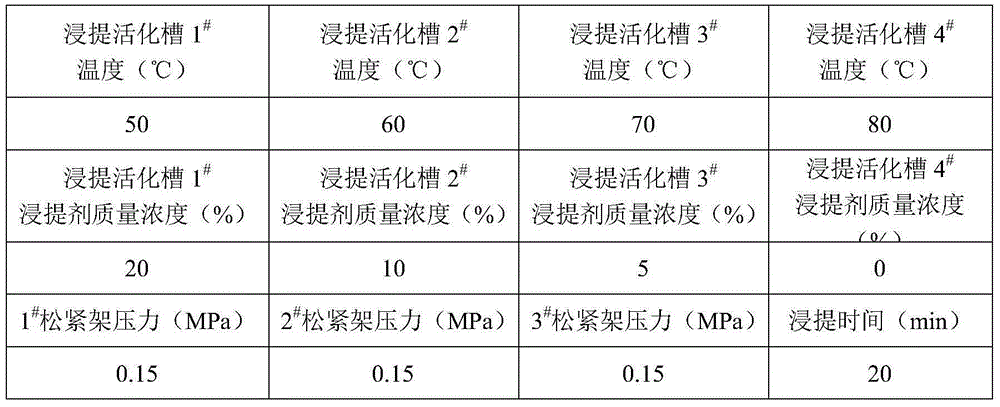

Embodiment 1

[0024] The acrylic-chlorinated fiber-doped carbon fiber fabric gray fabric finishing device is composed of cloth feeding equipment 1, leaching and activation tank 2, pre-drying equipment 3, tenter setting equipment 4 and cloth falling equipment 5, and the whole set of devices is an integrated linkage type; The extraction and activation tank 2 is connected by four levels of extraction and activation tanks. Water baffles are installed between the extraction and activation tanks of each level to make the extraction agent flow back in a serpentine shape. Rollers are installed at the fabric outlets of each level and adjacent to each other. Pneumatic swing elastic frame is installed between the four-stage leaching activation tank, pre-drying equipment 3 and tenter setting equipment 4.

[0025] When the above-mentioned device is used for post-finishing, the acrylic-chlorinated fiber-doped carbon fiber fabric gray cloth is first subjected to extraction treatment, then the treated fabri...

Embodiment 2

[0036] The acrylic-chlorinated fiber-doped carbon fiber fabric gray fabric finishing device is composed of cloth feeding equipment 1, leaching and activation tank 2, pre-drying equipment 3, tenter setting equipment 4 and cloth falling equipment 5, and the whole set of devices is an integrated linkage type; The extraction and activation tank 2 is connected by four levels of extraction and activation tanks. Water baffles are installed between the extraction and activation tanks of each level to make the extraction agent flow back in a serpentine shape. Rollers are installed at the fabric outlets of each level and adjacent to each other. Pneumatic swing elastic frame is installed between the four-stage leaching activation tank, pre-drying equipment 3 and tenter setting equipment 4.

[0037] When the above-mentioned device is used for post-finishing, the acrylic-chlorinated fiber-doped carbon fiber fabric gray cloth is first subjected to extraction treatment, then the treated fabri...

Embodiment 3

[0048] The acrylic-chlorinated fiber-doped carbon fiber fabric gray fabric finishing device is composed of cloth feeding equipment 1, leaching and activation tank 2, pre-drying equipment 3, tenter setting equipment 4 and cloth falling equipment 5, and the whole set of devices is an integrated linkage type; The extraction and activation tank 2 is connected by four levels of extraction and activation tanks. Water baffles are installed between the extraction and activation tanks of each level to make the extraction agent flow back in a serpentine shape. Rollers are installed at the fabric outlets of each level and adjacent to each other. Pneumatic swing elastic frame is installed between the four-stage leaching activation tank, pre-drying equipment 3 and tenter setting equipment 4.

[0049] When the above-mentioned device is used for post-finishing, the acrylic-chlorinated fiber-doped carbon fiber fabric gray cloth is first subjected to extraction treatment, then the treated fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com