Method for producing functional microbes with glutathione waste liquid

A technology of functional microorganisms and glutathione, applied in the field of microorganisms, can solve the problems of high capital construction investment and operation and maintenance costs, low utilization rate of waste recycling, and unreported research results, so as to improve the comprehensive utilization rate and added value. , Solve the effect of unstable product performance and quality, and solve the problem of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0036] Bacillus licheniformis (provided in the form of ampoule freeze-dried powder) was purchased from the China Industrial Microorganism Culture Collection Management Center, number CICC23584;

[0037] Lactobacillus acidophilus (provided form: freeze-dried powder in ampoules) was purchased from China Industrial Microorganism Culture Collection Management Center, No. CICC6074);

[0038] Candida utilis (provided in the form of ampoule freeze-dried powder) was purchased from the China Industrial Microorganism Culture Collection Management Center, No. CICC31188);

[0039] Bacillus subtilis (provided in the form of ampoule freeze-dried powder) was purchased from China Industrial Microorganism Culture Collection Management Center, number CICC20872).

[0040] 1) Activation of strains

[0041] (1-1) Activation of Bacillus licheniformis

[0042] Slant medium preparation: 0.5% peptone, 0.3% beef extract, 1.5% NaCl, 1.5% agar, pH 7.0, 121°C, 0.103MPa, sterilized for 30min, and prepare...

preparation Embodiment 2

[0088] Horizontal twin-shaft paddle mixer model SSHJ-4, total volume 4m 3 , each batch of mixing capacity is 2 tons, wherein the bran (water content 8.5%) of filling 1.7 tons, fermented liquid 0.3 tons, mixing time 60s, the material moisture that comes out from the mixer is 21.58%, Bacillus licheniformis bacteria content 2.60 ×10 8 CFU / mL; Bacillus subtilis content 2.54×10 8 CFU / mL; Candida utilis bacteria content 2.72×10 8 CFU / mL; Lactobacillus acidophilus content 4.87×10 8 CFU / mL; total number of viable bacteria 12.73×10 8 CFU / mL

[0089] Put the materials coming out of the mixer into trays, the depth of each tray is 4cm, send the trays to the three-dimensional rack of the drying room, the drying room is 12m×12m×3m, turn over the materials every 1h, and dry The drying room temperature is controlled at 37°C, and the drying time is 20 hours. 1.7 tons of dried solid functional microbial products are obtained. 8 CFU / mL; Bacillus subtilis content 2.26×10 8 CFU / mL; Candida ...

experiment example 1

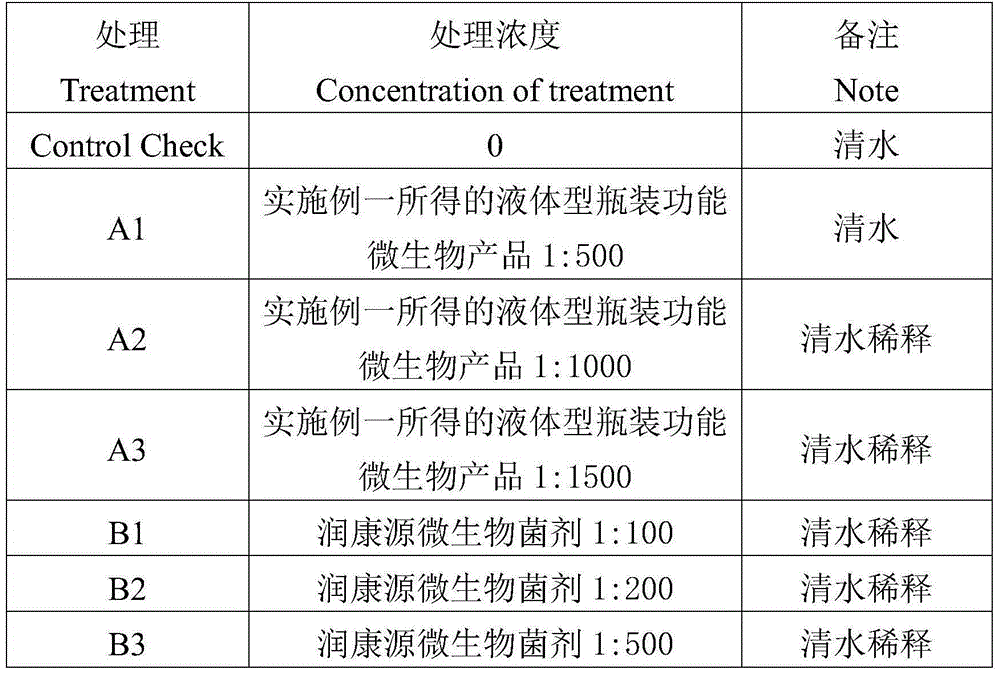

[0091] A comparative test was carried out with the liquid type bottled functional microorganism product obtained in Preparation Example 1 and the commercially available products produced by other companies.

[0092] Test site: located in the lettuce greenhouse of Jinan Agricultural High-tech Industry Demonstration Park

[0093] Trial period: September 30, 2014 to December 18, and March 1, 2015 to May 11. Sowing seedlings were carried out on September 30, 2014 and March 1, 2015; planting was carried out on October 28, 2014 and March 25, 2015, respectively, and the planting density was 20-25 cm in rows and plants; in December 2014 Harvested on the 10th and May 15th, 2015 respectively.

[0094] Varieties of lettuce to be tested: American fast-growing.

[0095] Test bacterial fertilizer and test design:

[0096] The liquid-type bottled functional microbial product obtained in Example 1 of the present invention is represented by A; Runkangyuan microbial bacterial agent (the stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com