Composite organic bacterial manure and preparation method of composite organic bacterial manure

A technology of organic bacteria and fertilizer, which is applied in the field of compound organic bacterial fertilizer and its preparation, can solve the problems of poor product quality, achieve the effects of promoting release, reducing the occurrence probability of viral diseases, and improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

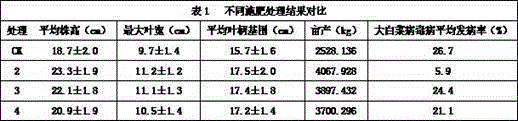

Image

Examples

Embodiment 1

[0015] Embodiment 1: a, 9 kilograms of medical stone, 11 kilograms of shell powder, 38 kilograms of camellia oleifera cake, 31 kilograms of goose manure, 36 kilograms of pig manure, 19 kilograms of potassium feldspar are pulverized and mixed evenly, then add Sporosporium thermophila 1.2 kg, fermented for 15 to 20 days at 44°C to 48°C;

[0016] b. Add 0.5 kg of Streptomyces luteus and 0.7 kg of Pediococcus pentosaceae to the mixture in step a, and ferment for 15 to 20 days at 34°C to 38°C; then add 1.1 kg of Trichoderma viride, ammonium chloride 23 kg fermented for 12-17 days at 27°C-30°C;

[0017] c. Mix the mixture in step b with 40 kilograms of sodium nitrate and 1.8 kilograms of azadirachtin, mix and stir evenly, dry and pack in bags.

Embodiment 2

[0018] Embodiment 2: a, 8 kilograms of medical stones, 10 kilograms of shell powder, 35 kilograms of camellia oleifera cake, 30 kilograms of goose manure, 33 kilograms of pig manure, 18 kilograms of potassium feldspars are pulverized and mixed evenly, then add Sporosporium thermophila 1 kg, fermented for 15 to 20 days at 44°C to 48°C;

[0019] b. Add 0.5 kg of Streptomyces luteus and 0.6 kg of Pediococcus pentosaceae to the mixture in step a, and ferment for 15 to 20 days at 34°C to 38°C; then add 1 kg of Trichoderma viride, ammonium chloride 22kg fermented for 12-17 days under the condition of 27℃~30℃; water can be added according to the situation during the fermentation process;

[0020] c. Mix the mixture in step b with 38 kilograms of sodium nitrate and 1 kilogram of azadirachtin, mix and stir evenly, dry and pack in bags.

Embodiment 3

[0021] Embodiment 3: a, 10 kilograms of medical stone, 12 kilograms of shell powder, 42 kilograms of camellia oleifera cake, 35 kilograms of goose manure, 38 kilograms of pig manure, 22 kilograms of potassium feldspar are pulverized and mixed evenly, then add Sporosporium thermophila 1.2 kg, fermented for 15 to 20 days at 44°C to 48°C;

[0022] b. Add 0.6 kg of Streptomyces luteus and 0.8 kg of Pediococcus pentosaceae to the mixture in step a, and ferment for 15 to 20 days at 34°C to 38°C; then add 1.2 kg of Trichoderma viride, ammonium chloride 25kg fermented for 12-17 days at 27°C-30°C;

[0023] c. Mix the mixture in step b with 45 kilograms of sodium nitrate and 2 kilograms of azadirachtin, mix and stir evenly, dry and pack in bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com