In-situ reinforcement method of recycled aggregate

A recycled aggregate and in-situ strengthening technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve equipment investment and production cost increase, non-in-situ strengthening of recycled aggregate, cement slurry Problems such as small water-cement ratio to achieve the effect of improving bond strength, avoiding production costs, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

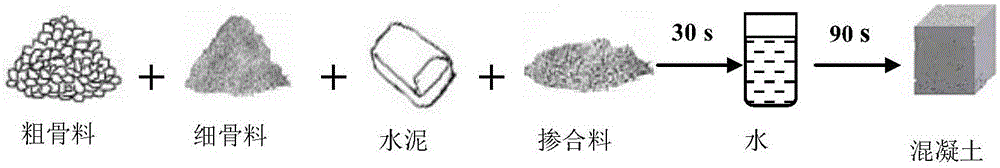

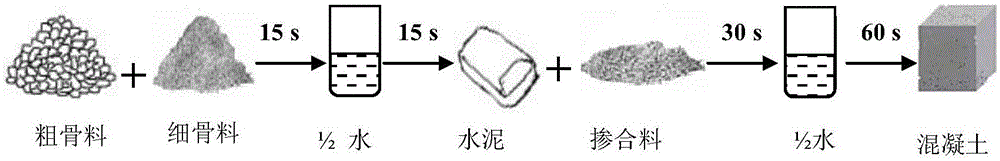

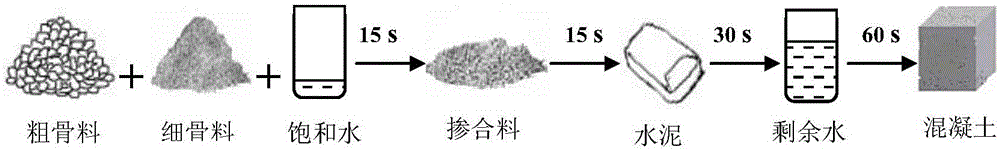

Method used

Image

Examples

Embodiment 1~8

[0026] Examples 1-8: In-situ strengthening and interface strengthening simulation of recycled aggregates

[0027] (1) Prepare old concrete with a slump of 30-50mm and a design strength grade of C30. After 60 days of natural curing, use a coring machine to drill a cylindrical core sample with a diameter of 100mm and a height of 150mm from the old concrete, and use it as a simulation recycled aggregate.

[0028] (2) Disperse the admixture in water to prepare an admixture dispersion. During preparation, add a water reducer in advance, and the mass ratio of the admixture, water and water reducer is 1:1:0.01. The types of admixtures are detailed in Table 1. The water reducer is a polycarboxylate high performance water reducer.

[0029] (3) After drying the simulated recycled aggregate, soak it in the admixture dispersion for 1min, then place it in the middle of the 150mm×150mm×150mm test mold, pour new concrete around it, and the concrete mix ratio used is the same as that of the...

Embodiment 9~16

[0039] Examples 9-16: Simulation test of in-situ strengthening of recycled aggregates and the effect of in-situ strengthening on the strength of recycled aggregate concrete

[0040] (1) Prepare old concrete with a slump of 30-50mm and a design strength grade of C30. After 60 days of natural curing, use a coring machine to drill a cylindrical core sample with a diameter of 50mm and a height of 100mm from the old concrete, and use it as a simulation recycled aggregate. At the same time, the rest of the old concrete is crushed, screened, and dried to obtain recycled coarse aggregate with a nominal particle size of 5-20mm and recycled fine aggregate with a nominal particle size of less than 5mm.

[0041] (2) The designed new concrete mix ratio is (mass ratio): (cement + admixture): water: fine aggregate: coarse aggregate = 1:0.50:1.71:2.58, and the fine aggregate used is natural medium sand and A mixture of one or two kinds of regenerated fine aggregates in step (1), the coarse a...

Embodiment 17~18

[0064] Examples 17-18: In-situ strengthening of different recycled aggregates

[0065] (1) Cylinder core samples with a diameter of 50mm and a height of 53mm were drilled in the sintered ordinary brick and the autoclaved lime-sand brick, respectively, and used as simulated recycled aggregate. Sintered ordinary bricks and autoclaved lime-sand bricks are crushed, screened and dried to prepare recycled coarse aggregate with a nominal particle size of 5-20mm and recycled fine aggregate with a nominal particle size of <5mm.

[0066] (2) New concrete mix ratio (cement+admixture) designed: water: fine aggregate: coarse aggregate = 1:0.50:1.71:2.58, and the admixture used is 20% fly ash (20% refers to powder The ratio of coal ash to the total mass of all admixtures and cement) and 20% slag micropowder (20% refers to the ratio of slag micropowder to the total mass of all admixtures and cement) are compounded, and the mass of all admixtures ( That is, the mass ratio of fly ash and slag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com