A kind of preparation method of self-supporting three-dimensional graphene

A graphene, self-supporting technology, applied in the field of preparation of self-supporting three-dimensional graphene, can solve the problems of waste of resources, complex preparation process, environmental pollution, etc., and achieves the improvement of current transmission capacity, the improvement of usability, and the good foaming effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using hexamethylenetetramine as a foaming agent and glucose as a carbon source to prepare three-dimensional graphene, the first step is to mix hexamethylenetetramine and glucose, stir into a uniform powder, and the second step is to heat up to a specified temperature and keep it for a certain period of time to prepare Self-supporting three-dimensional graphene foam.

[0021] Step 1. Mix glucose and hexamethylenetetramine at a mass ratio of 1:0.5.

[0022] Step 3. Under an inert atmosphere, heat the mixed powder to 1000°C at 4°C / min, and keep it warm for 0.5h;

[0023] Step 4, after the reaction is finished, take out the sample.

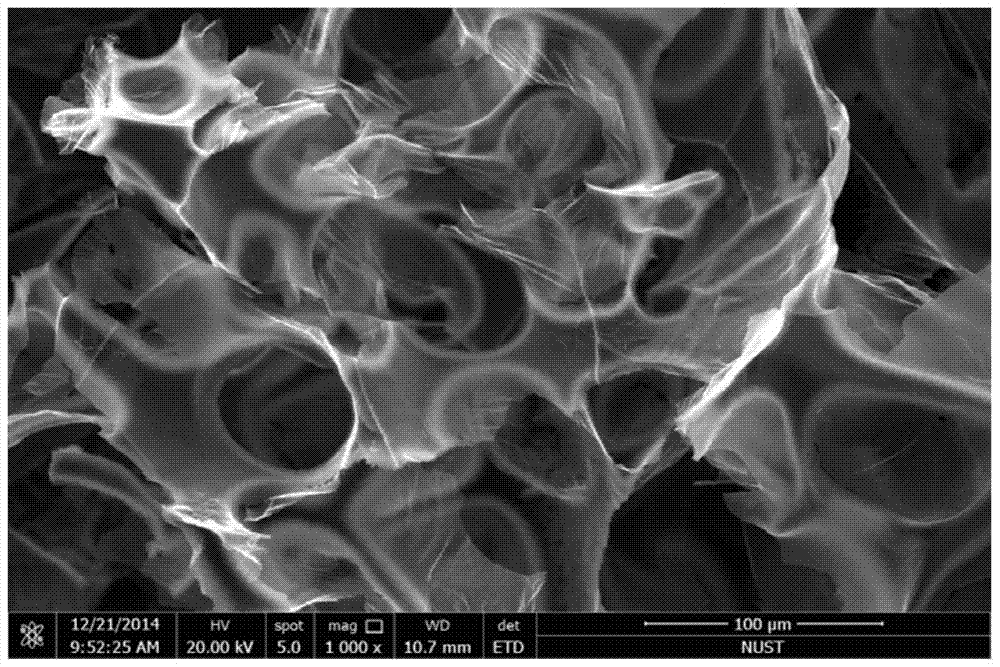

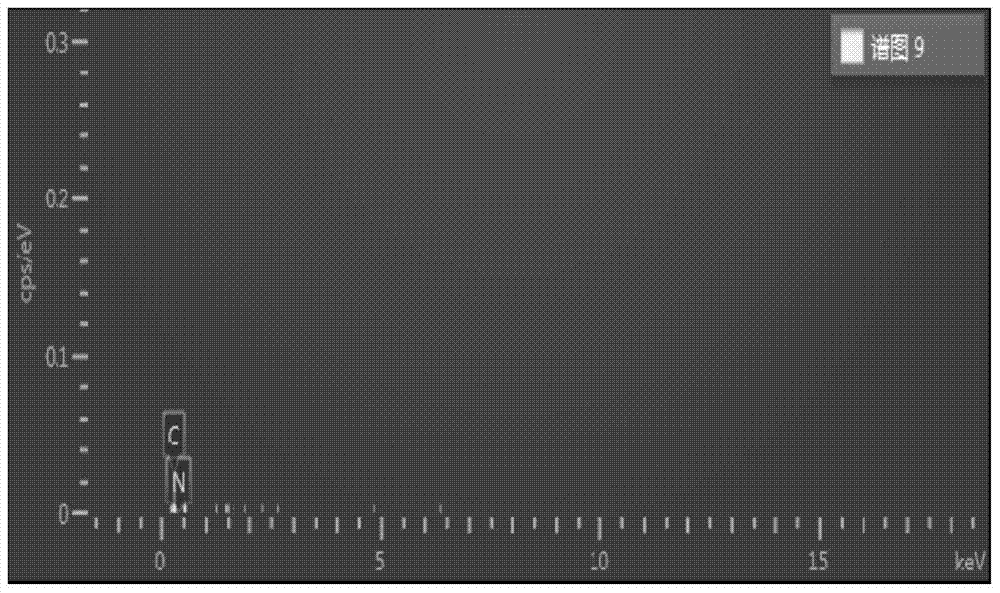

[0024] The samples were characterized by SEM and EDS as figure 1 , 2 shown. The results show that, according to the process parameters of Example 1, a three-dimensional graphene with a pore diameter of about 100 um, good light transmission, and self-supported by a carbon skeleton can be obtained.

Embodiment 2

[0026] Three-dimensional graphene is prepared by using hexamethylenetetramine as a foaming agent. The first step is to mix the carbon source and the foaming agent, and the second step is to raise the temperature to a specified temperature and keep it for a certain period of time to prepare a self-supporting three-dimensional graphene foam.

[0027] Step 1, mix glucose and hexamethylenetetramine with a mass ratio of 1:1, and place in the furnace body;

[0028] Step 2. Under an inert atmosphere, heat the powder at 8°C / min to 1200°C and keep it warm for 2 hours;

[0029] Step 3, the reaction furnace is cooled to room temperature, and after the reaction is completed, the sample is taken out.

[0030] The samples were characterized by SEM and EDS as in case 1.

Embodiment 3

[0032] Three-dimensional graphene is prepared by using hexamethylenetetramine as a foaming agent. The first step is to mix the carbon source and the foaming agent, and the second step is to raise the temperature to a specified temperature and keep it for a certain period of time to prepare a self-supporting three-dimensional graphene foam.

[0033] Step 1, mix glucose and hexamethylenetetramine with a mass ratio of 1:2, and place in the furnace body;

[0034] Step 2. Under an inert atmosphere, heat the powder at 10°C / min to 1400°C and keep it warm for 5 hours;

[0035] Step 3, the reaction furnace is cooled to room temperature, and after the reaction is completed, the sample is taken out.

[0036] The samples were characterized by SEM and EDS as in case 1.

[0037] The invention adopts a chemical foaming method and uses small nitrogen-containing organic molecules as a foaming agent to prepare nitrogen-doped three-dimensional graphene. Compared with the original plan using am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com