Highly-ordered mesoporous carbon spheres and preparation method thereof

A highly ordered, mesoporous carbon technology, applied in the field of inorganic materials, can solve problems such as complex steps, and achieve the effects of large preparation, high order, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

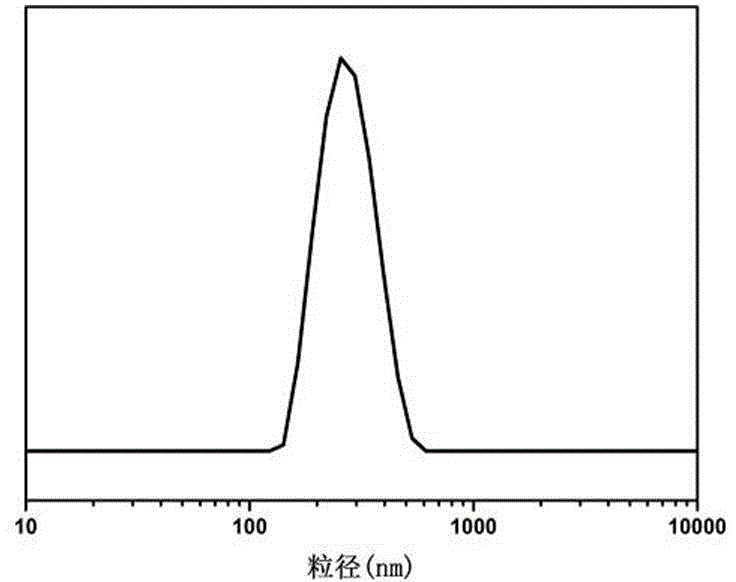

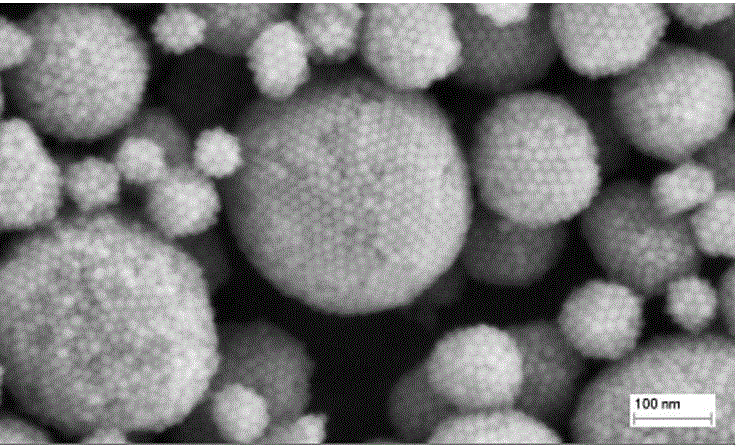

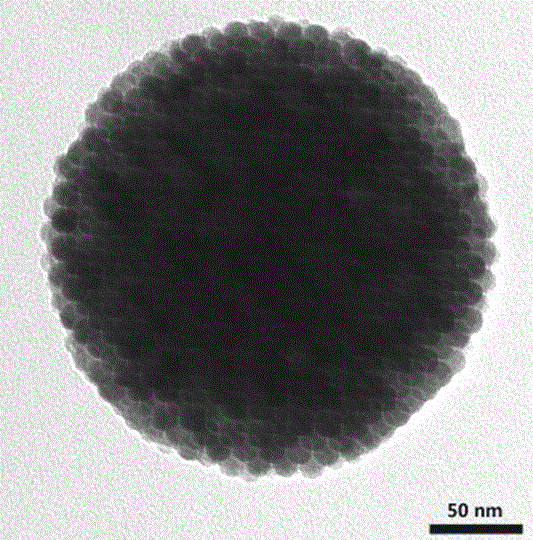

[0024] Example 1: 36g of iron oleate and 8.5g of oleic acid were dissolved in 200g of octadecene, and reacted at 320° C. for 1 hour under the protection of nitrogen to obtain ferric oxide nanoparticles with a particle size of about 14nm. Dissolve the obtained nanoparticles in 40ml of n-hexane, and then drop 20ml of this solution into 200ml of water containing 4g of dodecyltrimethylammonium bromide under stirring to form an O / W (oil-in-water) type emulsion, heat up and blow After the organic solvent is evaporated, the product is adsorbed by a magnet or centrifuged, the supernatant is discarded, and the obtained precipitate is washed with ethanol to obtain nanoparticle microspheres with a particle size of about 300nm and a highly ordered secondary structure. The obtained nanoparticle microspheres were calcined at 500° C. for 2 hours under nitrogen, so that the oleic acid molecules coated on the surface of the nanoparticles were carbonized, and the microspheres formed by stacking ...

Embodiment 2

[0025] Example 2: Dissolve 36 g of iron oleate and 8.5 g of oleic acid in 200 g of octadecene, and react at 320° C. for 1 hour under nitrogen protection to obtain ferric oxide nanoparticles with a particle size of about 14 nm. Dissolve the obtained nanoparticles in 40ml of n-hexane, and then drop 40ml of this solution into 200ml of water containing 8g of dodecyltrimethylammonium bromide under stirring to form an O / W (oil-in-water) type emulsion, heat up and blow After the organic solvent is evaporated, the product is adsorbed by a magnet or centrifuged, the supernatant is discarded, and the obtained precipitate is washed with ethanol to obtain spherical shells of nanoparticles with a particle size of about 1 μm and a highly ordered secondary structure. hollow microspheres. The obtained nanoparticle microspheres were calcined at 500° C. for 2 hours under nitrogen, so that the oleic acid molecules coated on the surface of the nanoparticles were carbonized, and the microspheres f...

Embodiment 3

[0026] Example 3: Dissolve 36 g of iron oleate and 8.5 g of oleic acid in 200 g of octadecene, and react at 280° C. for 1 hour under nitrogen protection to obtain ferric oxide nanoparticles with a particle size of about 6 nm. Dissolve the obtained nanoparticles in 40ml of n-hexane, and then drop 20ml of this solution into 200ml of water containing 4g of dodecyltrimethylammonium bromide under stirring to form an O / W (oil-in-water) type emulsion, heat up and blow After the organic solvent is evaporated, the product is adsorbed by a magnet or centrifuged, the supernatant is discarded, and the obtained precipitate is washed with ethanol to obtain nanoparticle microspheres with a particle size of about 300nm and a highly ordered secondary structure. The obtained nanoparticle microspheres were calcined at 500° C. for 2 hours under nitrogen, so that the oleic acid molecules coated on the surface of the nanoparticles were carbonized, and the microspheres formed by stacking highly order...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com