An ion desorption device and its operating method

A technology of desorption and ionization, which is applied in the field of ion desorption devices and desorption devices, can solve the problems of complex pipelines, few reports, and many valves, and achieve the effects of continuous operation process, simple equipment structure, and flexible process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

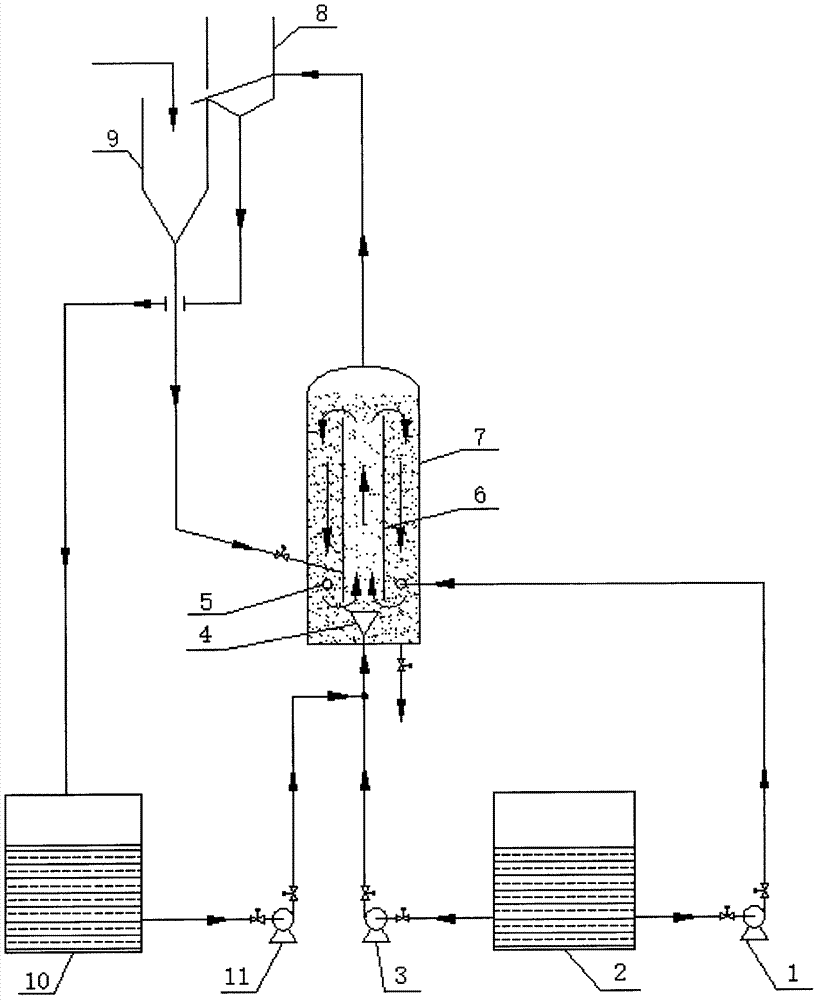

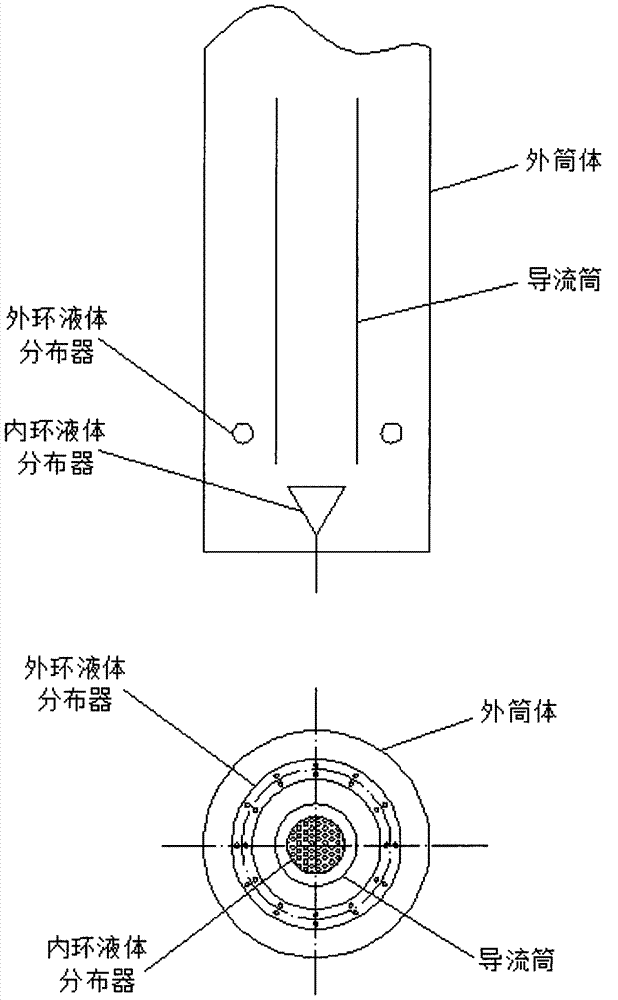

[0023] See attached figure 1 - attached image 3 , an ion desorption device of this embodiment is characterized in that it includes at least an ion desorption system, a liquid-solid separation system, a resin delivery system and a liquid delivery system. The ion desorption system mainly includes an inner ring liquid distributor 4, an outer ring liquid distributor 5, a guide cylinder 6 and an outer cylinder 7; the guide tube 6 and the outer cylinder 7 are coaxially placed inside the outer cylinder 7, and the inner ring The liquid distributor 4 is placed directly under the guide tube 6 inside the outer cylinder 7, and the outer ring liquid distributor 5 is placed inside the annular gap between the outer cylinder 7 and the guide tube 6; the liquid-solid separation system 8 is placed in the ion The top of the outer cylinder 7 of the desorption system is connected to it through a delivery pipeline; the resin delivery system includes at least a resin feeder 9 to be desorbed, and is...

Embodiment 2

[0030] See attached figure 1 , attached figure 2 And attached Figure 4 , an ion desorption device of this embodiment is the same as that of Embodiment 1.

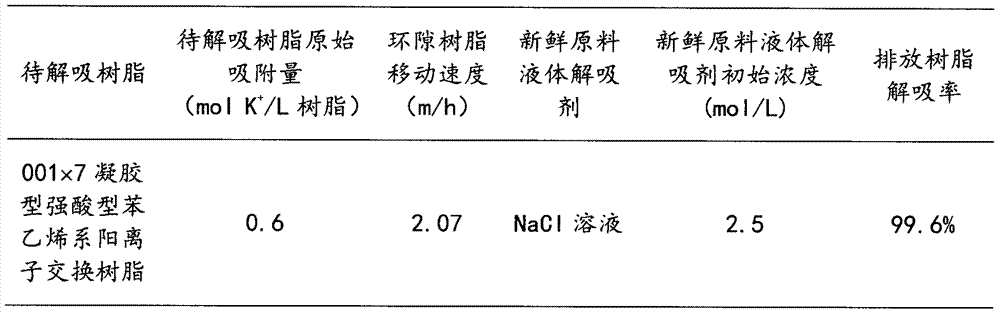

[0031] See attached figure 1 , attached figure 2 And attached Figure 4 , the operation method of an ion desorption device in this embodiment is characterized in that: the delivery pump 11 is turned on, the delivery pump 3 is turned off, and the first liquid desorbent from the desorption liquid storage tank 10 enters the guide via the inner ring liquid distributor 4 In the flow tube 6, the solid resin to be desorbed in the flow guide tube 6 is in contact with the turbulent bed state; the delivery pump 1 is turned on, and the second liquid desorbent from the fresh raw material liquid desorbent storage tank 2 passes through the outer ring liquid distributor 5 enters the annular gap between the outer cylinder 7 and the guide tube 6, and contacts with the solid resin to be desorbed in the annular gap in a moving bed sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com