Self-locking medical puncture needle and using method

A puncture needle and self-locking technology, applied in the field of self-locking medical puncture needles, can solve the problems of inability to fix the vein needle wing, change of the inner diameter of the hose, patient injury, etc. The effect of small product loss and stable sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

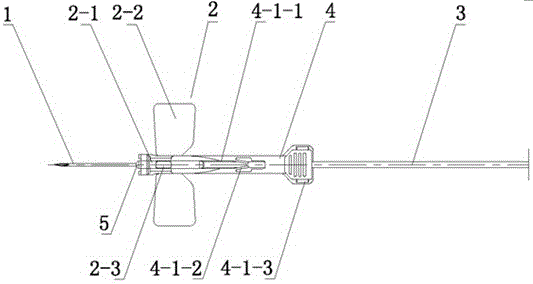

[0027] Such as Figure 1 to Figure 8 As shown, the self-locking medical puncture needle includes a puncture needle steel needle 1, a puncture needle needle holder 2, a hose 3, and a safety device 4. The puncture needle needle holder 2 includes a puncture needle seat 2-1 integrally formed by injection molding And puncture needle wing 2-2, puncture needle holder 2-1 is sleeved with hose 3 at the rear end; safety device 4 is composed of a strip bottom holder 4-2 and an upper cover 4-1, strip bottom holder 4-2 The upper cover 4-1 and the upper cover 4-1 are injection-molded into one body by two plastic hinges 4-3. The upper cover 4-1 is U-shaped, and a cantilever hook is provided on both sides of the end of the upper cover 4-1. 4-1-5, on the surface of the tail end of the strip bottom bracket 4-2, two rectangular holes 4-2- matched with the two cantilever hooks 4-1-5 of the upper cover 4-1 are respectively provided 2. When the cantilever hook 4-1-5 is engaged with the rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com