ZnSnN2 pn junction and preparation method thereof

A zinc tin nitride, pn junction technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., to achieve the effect of improving accuracy, reducing edge discharge effect, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

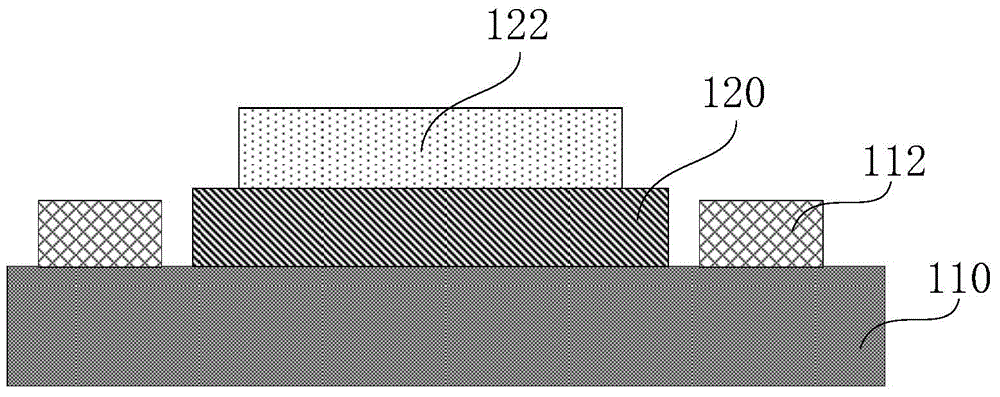

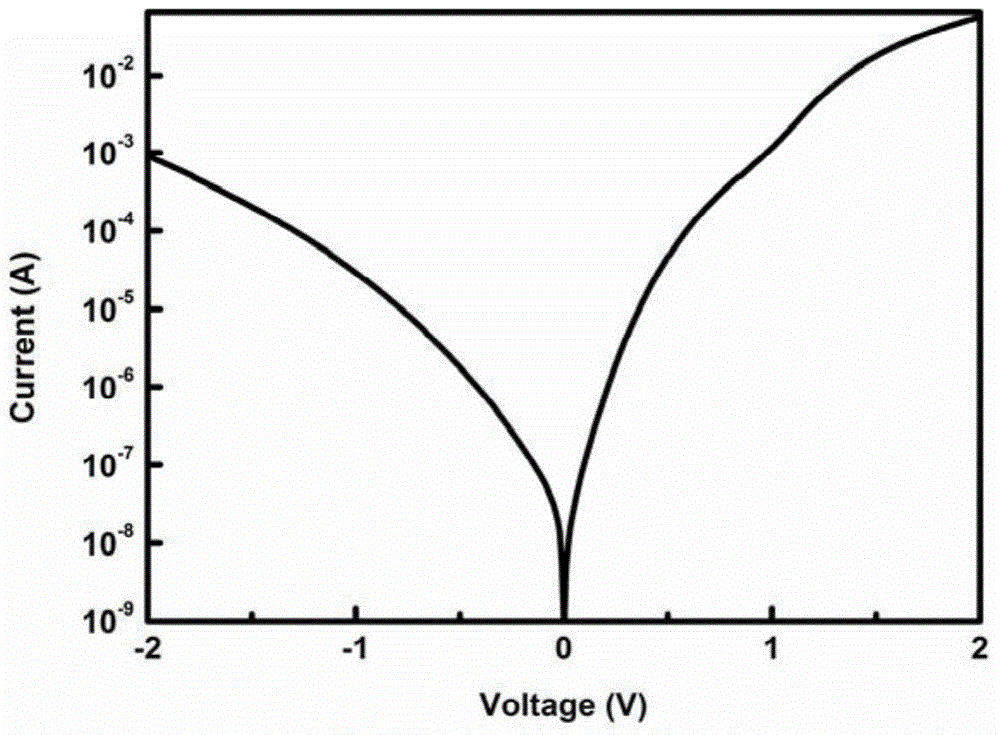

[0054] In the preparation process of the pn junction of the present invention, the n-type ZnSnN 2 If the deposition thickness of the semiconductor layer 120 is too small, the formed pn junction has poor performance and cannot meet practical applications; if the deposition thickness is too large, it not only increases the cost, but also is not conducive to the development trend of device miniaturization. Therefore, n-type ZnSnN 2 The thickness of the semiconductor layer 120 is preferably 60nm-300nm, within this thickness range, the obtained pn junction has obvious rectifying effect.

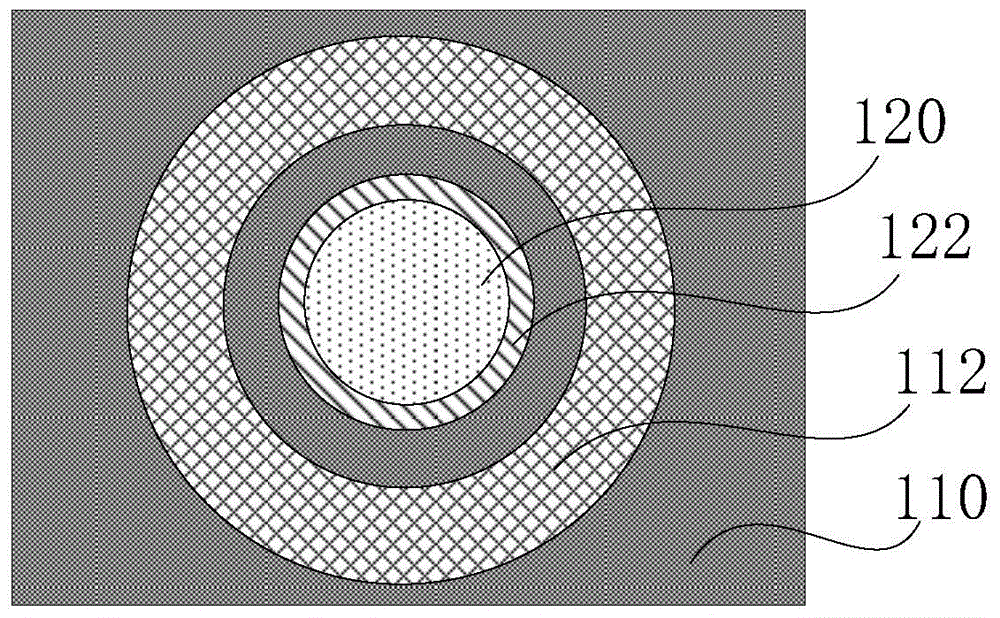

[0055] In the pn junction of the present invention, if the cross-sectional area of the electrode is too small, large resistance will be generated, and the preparation is difficult; if the cross-sectional area of the electrode is too large, electric leakage will easily occur and the safety performance of the device will be reduced. Preferably, as an implementation mode, n-type ZnSnN 2 The dia...

Embodiment 1

[0101] (1) Cut the p-type single-polished silicon wafer with ρ2 Sample silicon wafers, washed and dried;

[0102] (2) Deposit ZnSnN on p-type Si 2 . Sputtering at room temperature, set the background vacuum to 6×10 -4 Pa. The magnetron sputtering method is adopted under vacuum conditions, the sputtering power is 120W, and the working pressure is 2.0Pa. The cathode zinc-tin alloy target is bombarded with N ions, so that the target atoms are sputtered and react with N ions to form ZnSnN 2 , ZnSnN 2 The thickness is 120nm.

[0103] (3) In the sample ZnSnN 2 A layer of photoresist is spin-coated on the surface to form the first mask;

[0104] (4) Utilize the first mask of ultraviolet lithography;

[0105] (5) Corrosion of ZnSnN not protected by photoresist with etching solution 2 , to get the ZnSnN 2 The diameter of the cross-sectional circle is 100 μm.

[0106] (6) Utilize acetone and deionized water to clean the remaining photoresist in step (5);

[0107] (7) In Si-Zn...

Embodiment 2

[0112] (1) Cut the p-type single-polished silicon wafer with ρ2 Sample silicon wafers, washed and dried;

[0113] (2) Deposit ZnSnN on p-type Si 2 . Sputtering at room temperature, set the background vacuum to 6×10 -4 Pa. The magnetron sputtering method is adopted under vacuum conditions, the sputtering power is 120W, and the working pressure is 2.0Pa. The cathode zinc-tin alloy target is bombarded with N ions, so that the target atoms are sputtered and react with N ions to form ZnSnN 2 , ZnSnN 2 The thickness is 120nm.

[0114] (3) In the sample ZnSnN 2 A layer of photoresist is spin-coated on the surface to form the first mask;

[0115] (4) Utilize the first mask of ultraviolet lithography;

[0116] (5) Corrosion of ZnSnN not protected by photoresist with etching solution 2 , to get the ZnSnN 2 The diameter of the cross-sectional circle is 100 μm.

[0117] (6) Utilize acetone and deionized water to clean the remaining photoresist in step (5);

[0118] (7) In Si-Zn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com