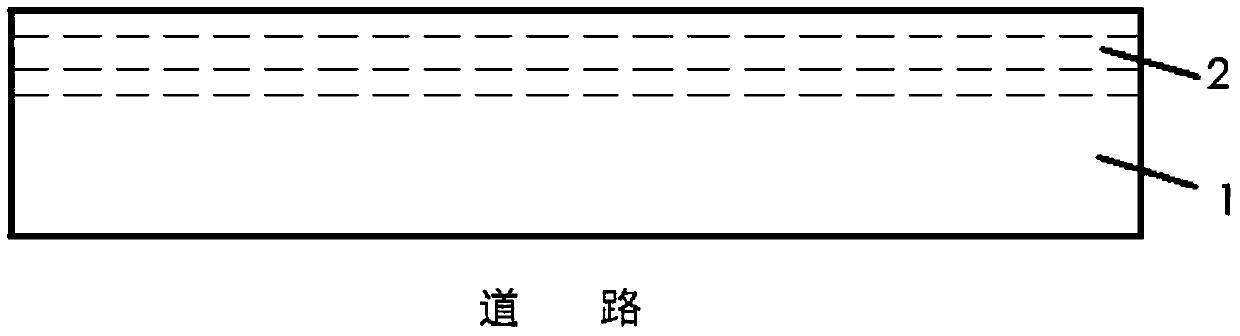

A semi-rigid composite beam anti-collision guardrail and its construction method

A technology of anti-collision guardrails and superimposed beams, applied in the directions of roads, road safety devices, roads, etc., can solve the problems of low service life, high maintenance cost, corrosion, etc., achieve high strength and durability, reduce maintenance times, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

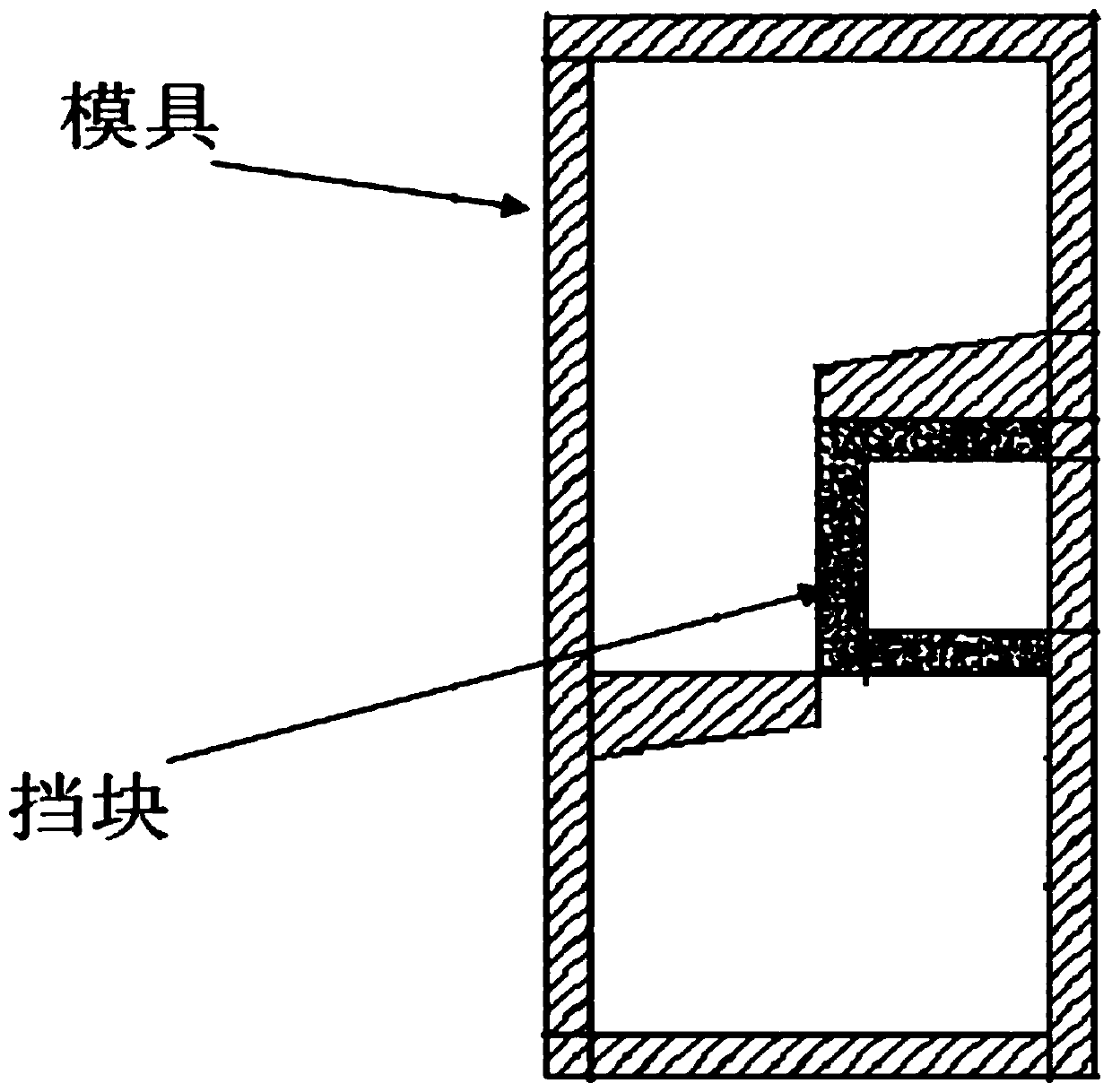

Method used

Image

Examples

Embodiment 1

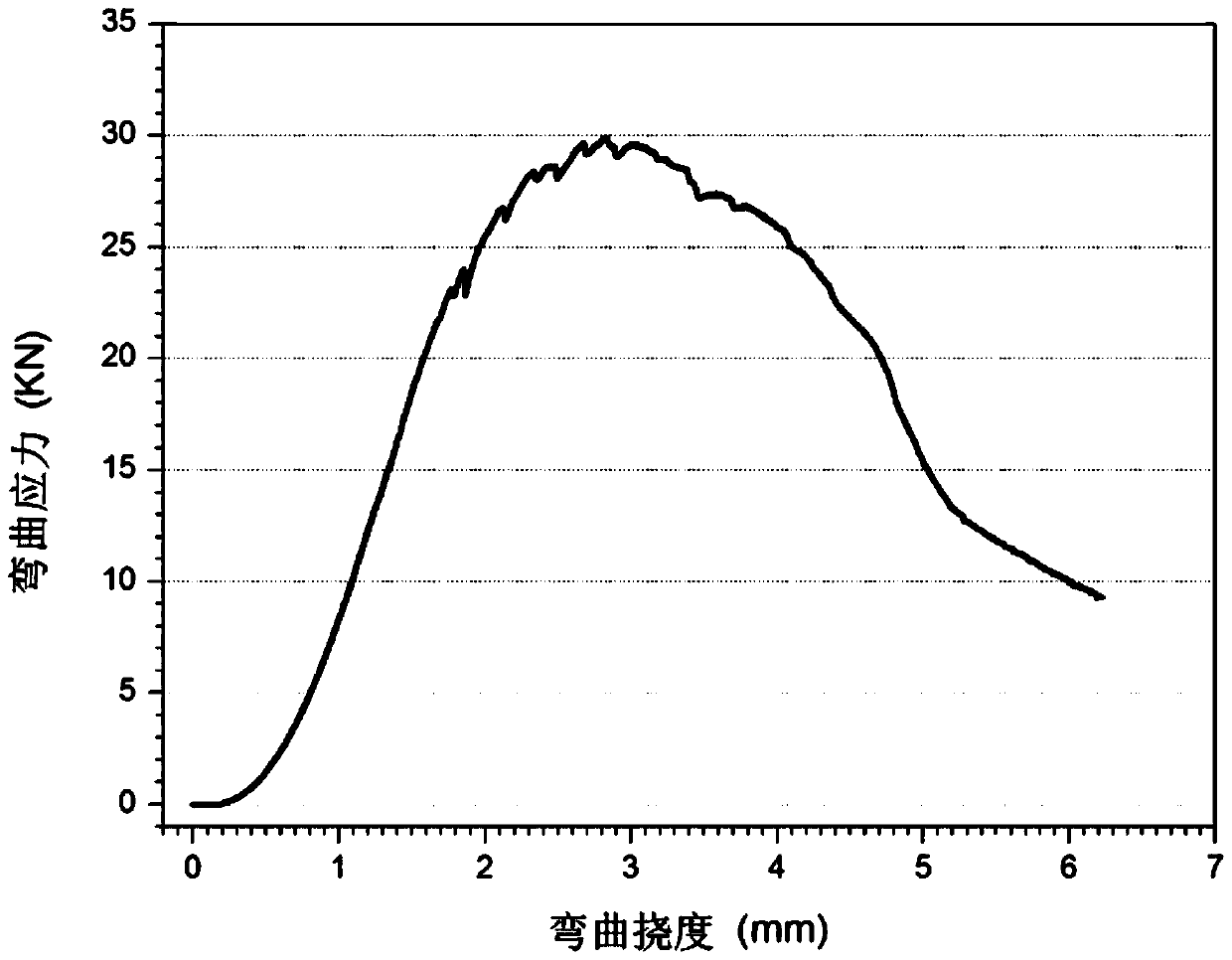

[0041] 1. Raw materials and mix ratio design:

[0042] The cementitious materials selected for the preparation of ecological nanoparticle-reinforced cement-based composites are P·II 52.5 Portland cement, Class I fly ash, and silica fume; the fine aggregate is continuous graded ordinary river with a maximum particle size of 2.36mm Sand; the steel fiber is ultra-fine steel fiber with a length of 13mm, an aspect ratio of 65, and a maximum tensile strength of 2850MPa; the solid percentage of high-performance water reducing agent is 40%, and the tax reduction rate is more than 40%. The ratio of raw materials is shown in Table 1.

[0043] Table 1. Mixing ratio of ecological nanoparticle-reinforced cement-based composites (kg / m 3 )

[0044]

[0045] (Note: SP refers to high-performance water reducer, the value in the table is the mass of active ingredients in the water reducer)

[0046] The cementitious materials selected for the preparation of ultra-high ductility cement-based...

Embodiment 2

[0062] 1. Raw materials and mix ratio design:

[0063] The cementitious materials selected for the preparation of ecological nanoparticle-reinforced cement-based composites are P·I 52.5 Portland cement, Class 1 fly ash, and silica fume; Sand; the steel fiber is ultra-fine steel fiber with a length of 13mm, an aspect ratio of 65, and a maximum tensile strength of 2850MPa; the solid percentage of the high-performance water reducer is 40%, and the water reducing rate is above 40%. The ratio of raw materials is shown in Table 3.

[0064] Table 3. Mixing ratio of ecological nanoparticles reinforced cement-based composites (kg / m 3 )

[0065]

[0066] (Note: SP refers to high-performance water reducer, the value in the table is the mass of active ingredients contained in the water reducer)

[0067] The cementitious materials selected for the preparation of ultra-high ductility cement-based composite materials are P II 42.5 Portland cement; Class I fly ash; S95 class granulated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com