Hard copper busbar annealing method, processed hard copper busbar product and conductive part

An annealing treatment and copper busbar technology, which is applied in the field of hard copper busbar annealing treatment, conductive parts, and hardened copper busbar processed products. Scrap rate and the effect of improving elongation after break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The hard copper busbar annealing treatment method of this embodiment includes placing the hard copper busbar after blanking in an ordinary box-type resistance furnace, annealing at an annealing temperature of 340 ° C for 240 minutes, and then cooling naturally in the air to room temperature.

[0038] The hard copper busbar processed product of this embodiment is that the hard copper busbar after blanking is placed in an ordinary box-type resistance furnace, annealed at an annealing temperature of 340 ° C for 240 minutes, and then naturally cooled in the air to Serve at room temperature.

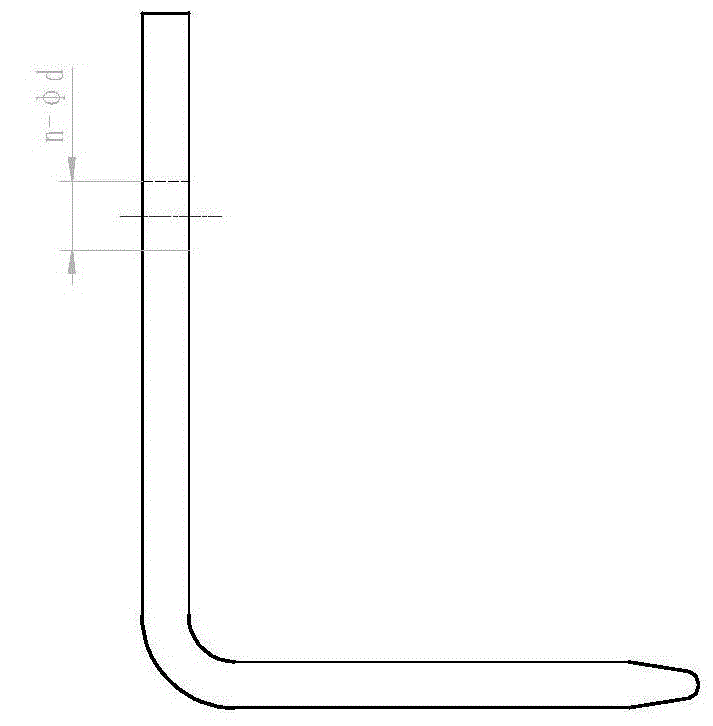

[0039] The conductive part of the present embodiment is made by cold stamping of the hard copper bus bar processed product obtained above, and the formed conductive part is figure 1 High voltage switch contacts shown.

Embodiment 2

[0041] The hard copper bus bar annealing treatment method of the present embodiment comprises placing the hard copper bus bar after blanking in a well-type resistance furnace, annealing at an annealing temperature of 350° C. for 180 min, and then cooling naturally in air to room temperature.

[0042] The processed hard copper busbar in this embodiment is to place the blanked hard copper busbar in a well-type resistance furnace, heat it at an annealing temperature of 350°C for 180min for annealing treatment, and then cool it naturally in the air to room temperature , that is.

[0043] The conductive part of the present embodiment is made by cold stamping of the hard copper bus bar processed product obtained above, and the formed conductive part is figure 2 terminal block shown.

Embodiment 3

[0045] The method for annealing the hard copper busbar in this embodiment includes placing the blanked hard copper busbar in a vacuum annealing furnace, annealing at an annealing temperature of 350° C. for 180 minutes, and then naturally cooling to room temperature in clear water .

[0046] The processed hard copper busbar of this embodiment is to place the blanked hard copper busbar in a vacuum annealing furnace, heat it at an annealing temperature of 350° C. for 180 minutes for annealing treatment, and then cool it naturally in clear water to room temperature. Instantly.

[0047]The conductive part of the present embodiment is made by cold stamping of the hard copper bus bar processed product obtained above, and the formed conductive part is image 3 The shunt row shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com